21

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

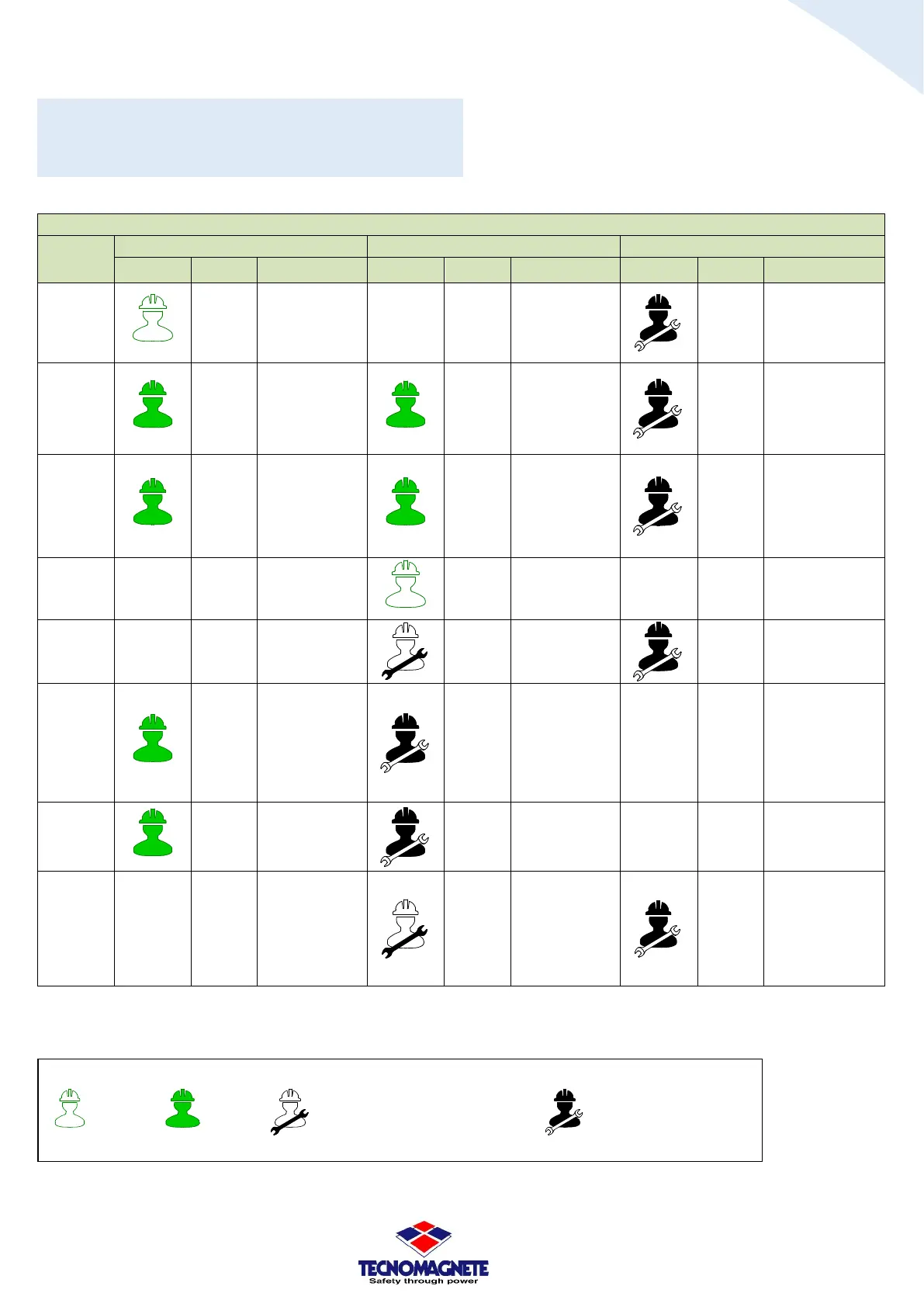

CHECKS and MAINTENANCE tabel

Component

subject to

control

skill

method objective

skill

method objective skill

method objective

Labels

Visual check

Checking integrity and

legibility

Within 6

months

Visual

inspection

Checking the presence of

the labels and their

legibility. Clean or, if

necessary, ask

TECNOMAGNETE to

replace it with equivalent

labels.

Pin lever

(for lever lock)

Operational

test

Check for slip and spring

return.

Keep the operating area

of the lever lock pin

clean.

Monthly

Operational

test

Checking of the sliding

and the spring return.

Carefully clean the

operating area of the

lever lock pin.

Within 6

months

Visual

inspection +

Operational

test

Check for the presence of

dust and dirt that could

obstruct the fluid

movement of the locking

pin. Clean with care or ask

TECNOMAGNETE for an

adequate technical

intervention.

Lever

Operational

test

Check the smoothness

of the lever rotation

(subject to the

conditions described in

chapter 9). Keep the

lever operating area

clean

Monthly

Operational

test

Checking of the sliding

and the spring return.

Carefully clean the

operating area of the

lever lock pin

Within 6

months

Visual

inspection +

Operational

test

Check for the presence of

dust and dirt that inhibit

the smooth rotation of the

lever (subject to the

conditions described in

chapter 9). Clean carefully

or ask TECNOMAGNETE for

adequate technical

assistance if necessary.

Body and

lever

Weekly

Visual

inspection

Checking the state of

wear and the absence of

oxidation

Body and

lever

Weekly

Visual

inspection

Verification of the

absence of oxidation (if

necessary, lubricate

with suitable product

and dose)

Annual

Visual

inspection

If the method proves to be

inefficient, ask

TECNOMAGNETE for

adequate technical

assistance.

Eyebolt /

Load ring

Visual check

Verification of the

absence of deformation

Quarterly

Visual

inspection

Check that there are no

dimensional

deformations beyond

10% of the values

indicated in the table

Fig.5.2B of paragraph

5.2.

See note below (

❋

).

If necessary, contact

TECNOMAGNETE

Poles

Visual check

Verification of the

absence of deformation

Quarterly

Visual

inspection

Check that there are no

deformations, dents,

roughness, roughness in

a value >10%. If

necessary, contact

TECNOMAGNETE

Complete

MaxX

Monthly

Operational

test

Check the tightening of

all screws in according

to Fig.10.10 of

paragraph 10.10

Annual

Functional

test and/or

operational

test

Where possible, carry out a

tear-off test with a

dynamometric machine to

measure the magnetic

clamping force. If possible,

contact TECNOMAGNETE

to request adequate

technical assistance with a

suitable measuring

instrument.

(❋)

verify that the value

M

indicated in the table Fig.5.2B paragraph 5.2 concerning the eyebolt

/

load ring does not decrease by

more than 10% (the eyebolt and the load ring are subject to wear / dent / consumption)

10.11 Summary table

Maintenance/Checks

Fig.10.11

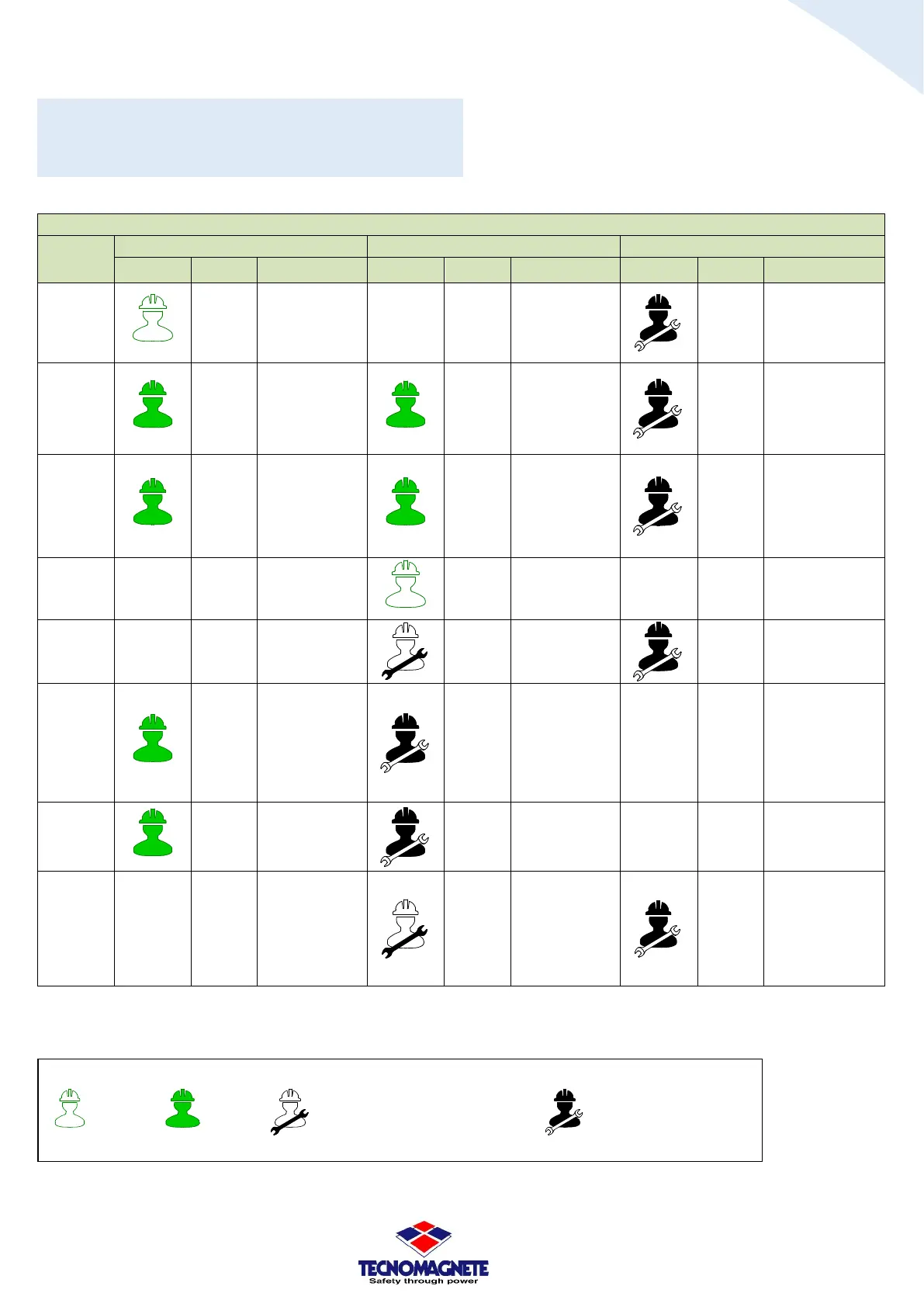

Legend of competences as per paragraph 1.7 TRAINED PERSONNEL

OPERATOR HANDLER

MECHANICAL MAINTENANCE TECHNICIAN SPECIALIZED TECHNICIAN

Loading...

Loading...