Use and Maintenance Manual

MaxX

9

MAXX

The following is the basic operating procedure for

using the MaxX

9.1

Operating procedure

Magnetizing and handling

Before using MaxX

, check that the poles and the contact

surface of the load to be lifted (Fig.9.1.1

) are clean so that

there is no residue of heavy dust and/or chips.

Also clean and check the correct function

stop lever (Fig.9.1.2

) in order to guarantee its functioning

in optimal conditions (check of the spring return).

Fig.9.1.1

Position MaxX

on the load to be handled paying attention

to its characteristics, with attention to the thickness, as

indicated in paragraph 5.1.

The poles of the MaxX

must be in perfect and total contact

with the load to be handled.

Make sure that the poles of the

centered on the load with g

anchoring of a round or a pipe.

Now proceed with the following steps:

a) Activate MaxX

by turning the lever to the MAG

position.

Fig.9.1A

PROPER USE OF

The following is the basic operating procedure for

Operating procedure

-

, check that the poles and the contact

) are clean so that

there is no residue of heavy dust and/or chips.

Also clean and check the correct function

ing of the pin-

) in order to guarantee its functioning

in optimal conditions (check of the spring return).

1.2

on the load to be handled paying attention

to its characteristics, with attention to the thickness, as

must be in perfect and total contact

MaxX

are perfectly

reater attention to the

by turning the lever to the MAG

b)

Turn the lever until it locks into the mechanical

lever lock.

Fig.9.1B

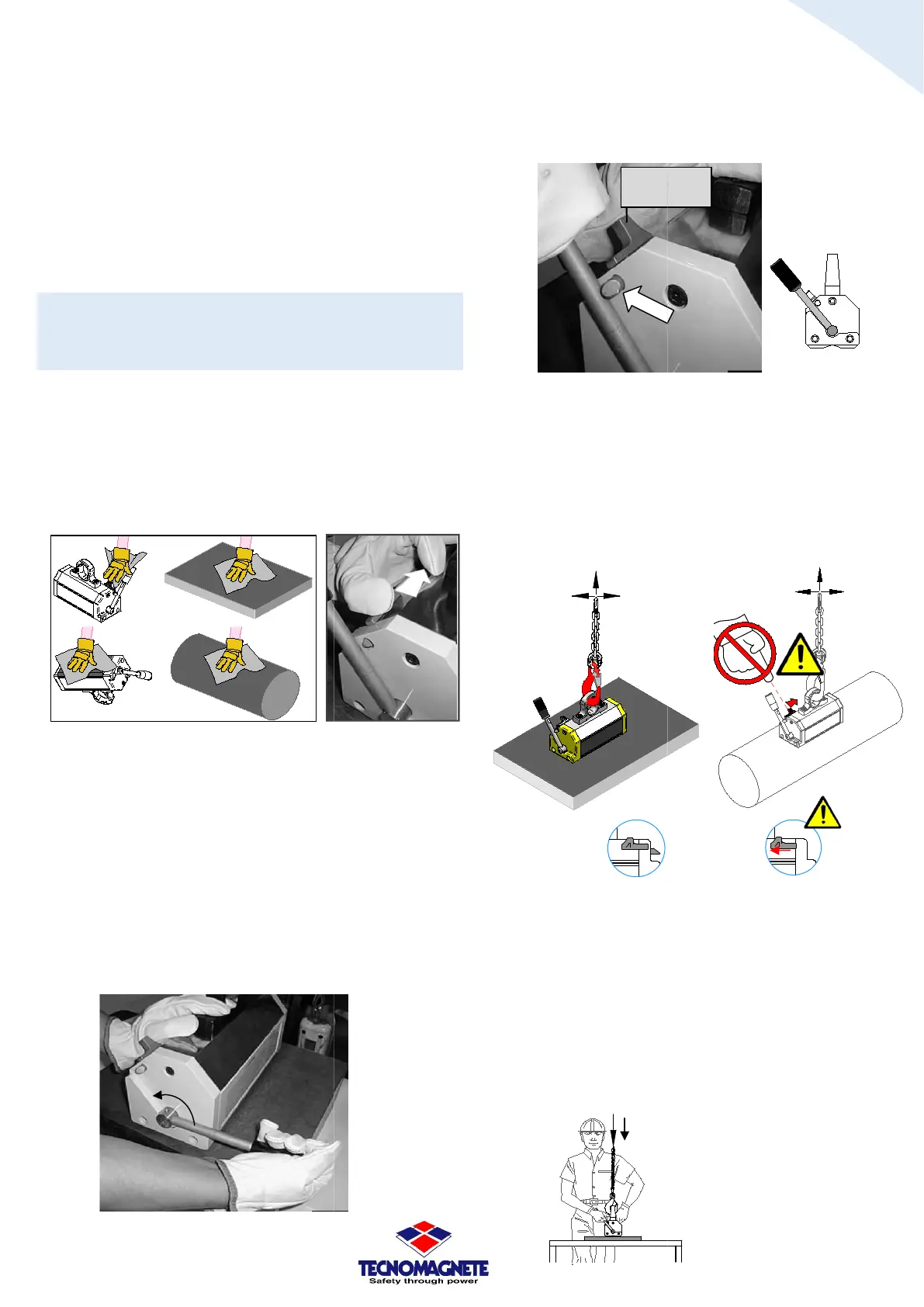

c)

Pay attention to the weight of the

(see paragraph 5.2 in the table Fig.5.2B) plus the

addition of the weight of the load, after which lift,

by means of a suitable lifting device, and move by

hooking MaxX

from the eyebolt/

the conditions suggested in paragraphs 2.2 a

5.1).

Fig.9.1C1

CAUTION: DO NOT ACIDENTALLY MOVE THE STOP

WITH THE SUSPENSION LOAD, especially for loads with a

high air gap (e.g.: rounds, tubes) because it could cause

the load to come

off and fall accidentally (with the load

anchored NOT in optimal conditions if you move the lever

stop device, bringing it to the OUT service position

Fig.9.1C4

, it could cause the sudden rotation of the lever

from the MAG position to the DEMAG position).

d)

Place the load perfectly on the ground or on a

support suitable for supporting the weights of both

the load and the

Fig.9.1D

Pin lever

(for lever lock)

18

codice 09MAXX001

versione EN

revisione 01

Turn the lever until it locks into the mechanical

Pay attention to the weight of the

MaxX model

(see paragraph 5.2 in the table Fig.5.2B) plus the

addition of the weight of the load, after which lift,

by means of a suitable lifting device, and move by

from the eyebolt/

load ring (observe

the conditions suggested in paragraphs 2.2 a

nd

Fig.9.1C2

CAUTION: DO NOT ACIDENTALLY MOVE THE STOP

-LEVE

WITH THE SUSPENSION LOAD, especially for loads with a

high air gap (e.g.: rounds, tubes) because it could cause

off and fall accidentally (with the load

anchored NOT in optimal conditions if you move the lever

stop device, bringing it to the OUT service position

, it could cause the sudden rotation of the lever

from the MAG position to the DEMAG position).

Place the load perfectly on the ground or on a

support suitable for supporting the weights of both

MaxX

.

IN

service

OUT

service

Loading...

Loading...