7

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

1.12

Nameplate data

Two plates are applied on the MaxX:

1) Logo and data referring to the identification of the

manufacturer, serial number, production date, weight of the

MaxX, symbology in compliance with the laws in force

(example Fig.1.12A).

2) Load / force curves, data referring to the performances and

dimensions and types of load to be magnetically anchored

(example Fig.1.12B).

3) The plates are indelible and must not be removed for any

reason even should the MaxX be sold.

In the event the plate

has been damaged or lost after coming away from its

housing, contact TECNOMAGNETE S.p.A. to obtain a

replacement. When communicating with TECNOMAGNETE

S.p.A., always quote the model on the plate. Failure to

comply with these provisions exempts

TECNOMAGNETE S.p.A. from any liability for damage or

injury to persons or property that may arise, which shall

remain the sole responsibility of the user with regard to the

competent bodies.

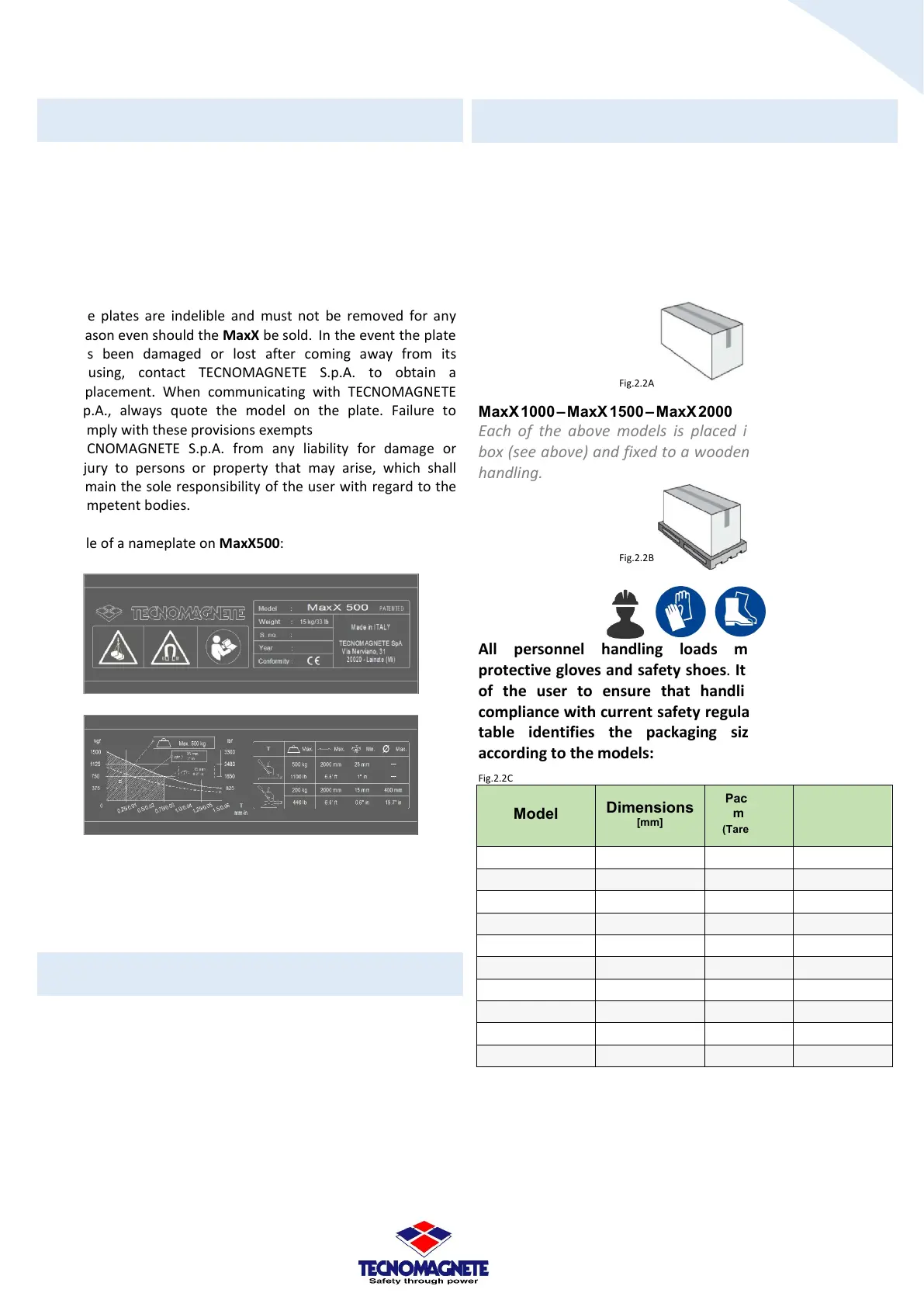

Example of a nameplate on MaxX500:

Fig.1.12A

Fig.1.12B

2 TRANSPORT AND

HANDLING

2.1

Receipt

MaxX are thoroughly checked before shipment. On receipt, the

integrity of the package and the material contained therein must

be checked (unless other instructions are issued by

TECNOMAGNETE S.p.A.), in order to confirm that no damage

occurred during transport and that the consignment complies

with the order specifications.

Otherwise, report any irregularities

to TECNOMAGNETE S.p.A. and the Carrier responsible for any

damage during transport.

Notification of damage or defects must be given within ten days

from receipt of the supply. After that period, TECNOMAGNETE

S.p.A. will consider the provision free of defects.

2.2

Handling

MaxX

125

–

MaxX

250

–

MaxX

300E

–

MaxX

500

–

MaxX

600E

MaxX

TG

150

–

MaxX

TG

300

Each of the above models is placed inside cardboard boxes,

protected by a sheet and wrapped in a layer of

polyurethane foam that guarantees the absolute

mechanical integrity in case of shocks or incidents of the

packaging.

Fig.2.2A

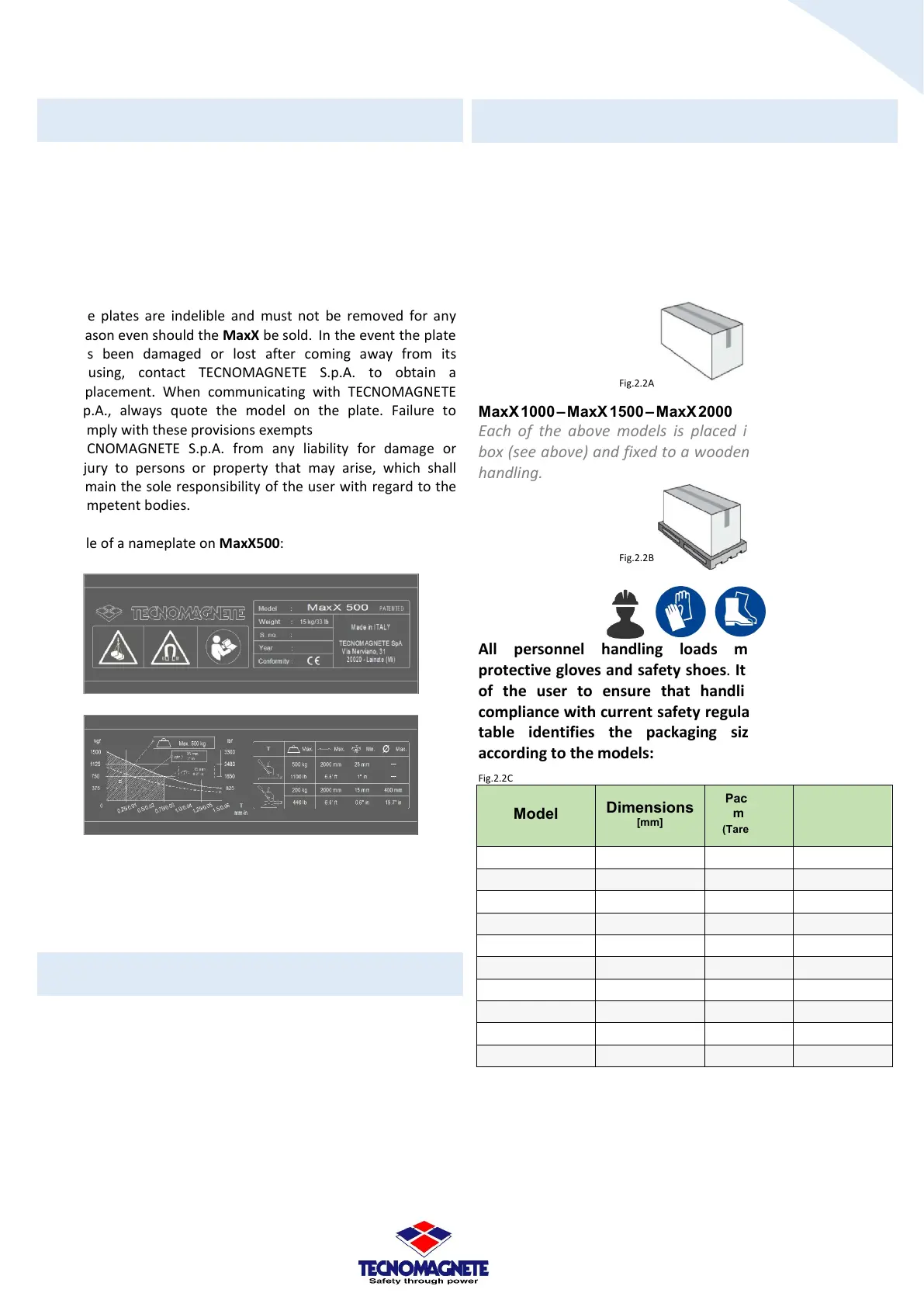

MaxX

1000

–

MaxX

1500

–

MaxX

2000

Each of the above models is placed inside the cardboard

box (see above) and fixed to a wooden pallet to allow easy

handling.

Fig.2.2B

All personnel handling loads must operate with

protective gloves and safety shoes. It is the responsibility

of the user to ensure that handling is conducted in

compliance with current safety regulations. The following

table identifies the packaging size and its weight

according to the models:

Fig.2.2C

Model

Dimensions

[mm]

Packing

mass

(Tare) [kg]

Complete

packing

(Gross) [kg]

MaxX 125

130x130x200 0.3 4

MaxX 250

195x145x200 0.5 7

MaxX 300E

195x145x200 0.5 7

MaxX 500

255x190x245 1 16

MaxX 600E

255x190x245 1 16

MaxX 1000

350x230x250 3.5 36

MaxX 1500

400x300x300 5 66

MaxX 2000

460x300x300 6 82

MaxX TG150

195x145x200 0.5 7

MaxX TG300

255x190x245 1 16

Loading...

Loading...