Use and Maintenance Manual

MaxX

9.2

Demagnetisation

Demagnetize with the load perfectly on the

ground or on a support suitable for supporting the

weights of both the load and the MaxX.

a)

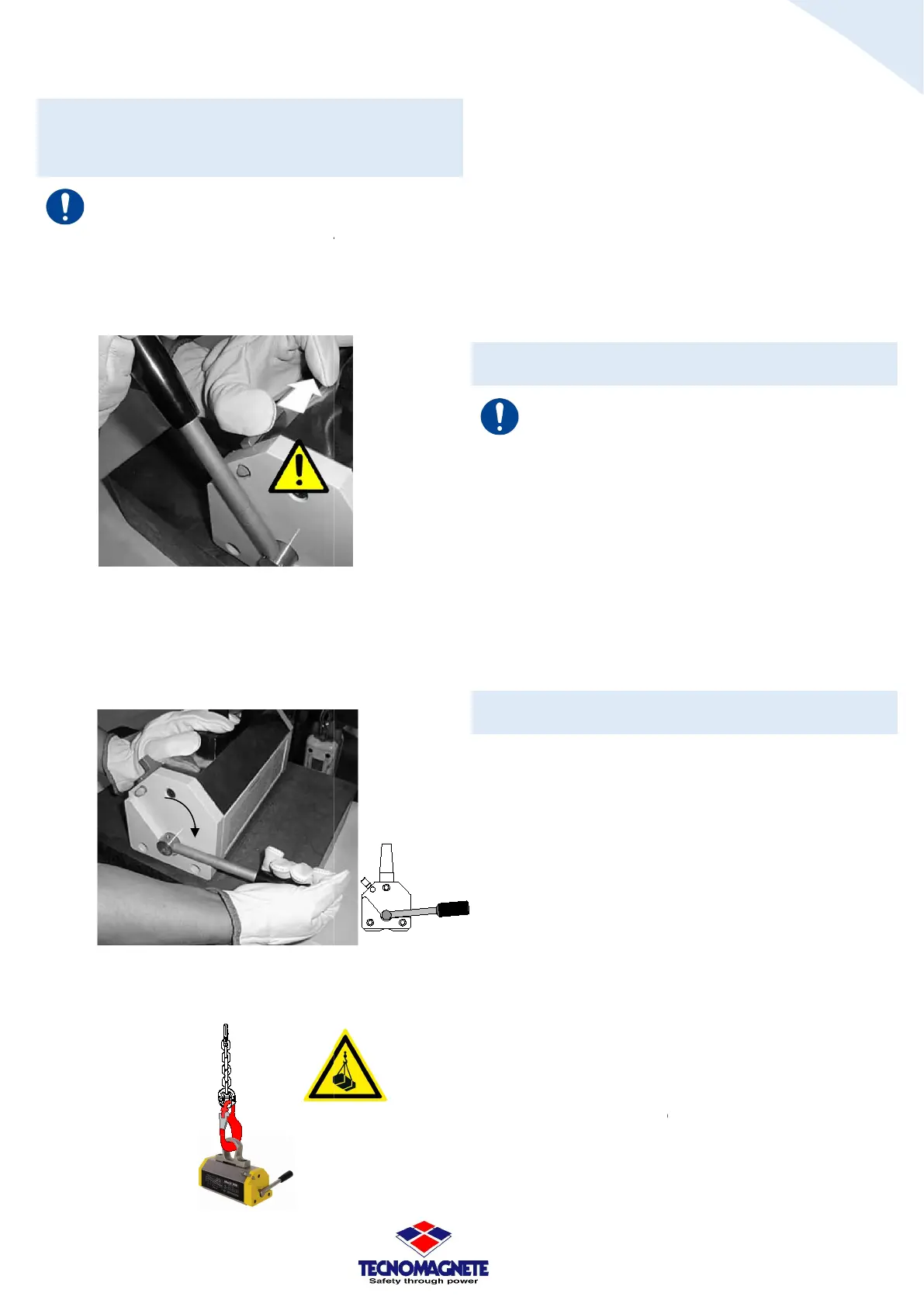

Manually move the mechanical lever stop device

until the lever is released during movement.

Fig.9.2A

b)

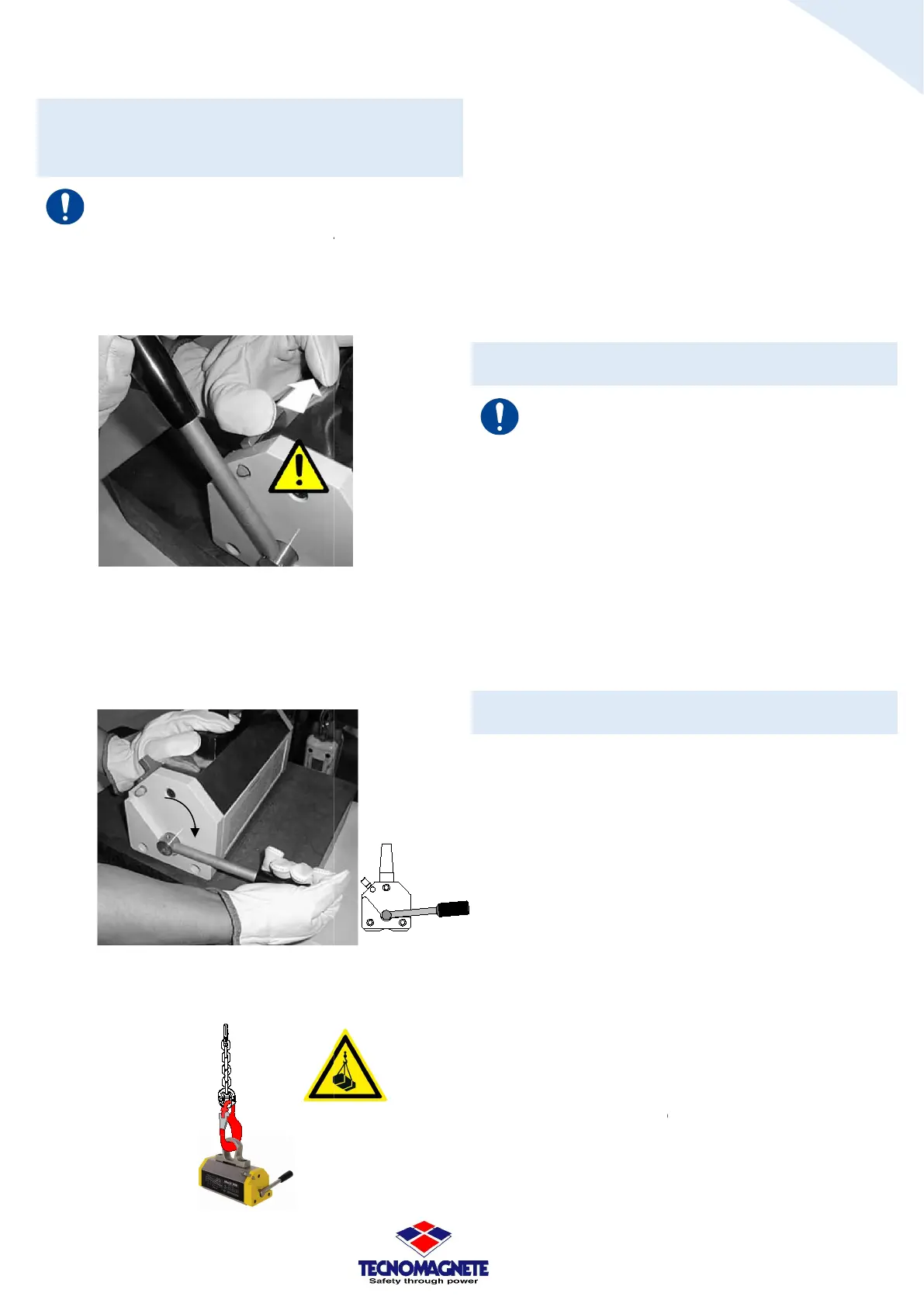

Holding with one hand the lever stop device in

position as described in phase a)

the lever, with the other hand, and make it rotate

until it accompanies it to the end stop in DEMAG

position.

Fig.9.2B

c) Move MaxX

with the same procedure described in

paragraph 7.1 in step a).

Fig.9.2C

-

Demagnetize with the load perfectly on the

ground or on a support suitable for supporting the

Manually move the mechanical lever stop device

until the lever is released during movement.

Holding with one hand the lever stop device in

proceed holding

the lever, with the other hand, and make it rotate

until it accompanies it to the end stop in DEMAG

with the same procedure described in

10

CHECKS and

MAINTENANCE

Adequate checks and maintenance are key factors in

ensuring that the MaxX

will last longer under optimum

operating and performance conditions and that it is

functionally safe over time.

10.1Controls –

Work equipment must be subject to periodic

inspections at frequencies determined on the basis of the

information supplied by the manufacturers, or the

standards of good practice, or in the absence thereof,

which can be inferred from the codes of good practice.

For this purpose, the types of contro

technical standards

1:2014 are reported:

DAILY CONTROL:

10.2 Checks -

Met

Below are the descriptions of

to the inspection methods:

VISUAL CHECK:

examination conducted with the

aim of identifying any anomalies or deviations

from normal conditions by means of visual checks.

Generally, the visual inspection is conducted

without disa

ssembling the equipment, unless there

are particular needs that may arise.

NON DESTRUCTIVE CHECK:

examinations such as penetrating liquids,

ultrasounds, magnetic particles, X

be necessary after the visual examination

FUNCTIONAL

TEST

controls, levers, indicator screws, etc. Functional

tests are those that allow to obtain a value or a

measure.

OPERATIONAL TEST

without load and/or tests for the functioning of the

device

s (with greater attention to the limiting

devices and indicators).

19

codice 09MAXX001

versione EN

revisione 01

Adequate checks and maintenance are key factors in

will last longer under optimum

operating and performance conditions and that it is

Standards

Work equipment must be subject to periodic

inspections at frequencies determined on the basis of the

information supplied by the manufacturers, or the

standards of good practice, or in the absence thereof,

which can be inferred from the codes of good practice.

For this purpose, the types of contro

ls derived from the

-1:2016 and ISO 12482-

see paragraph 10.4

: see paragraph 10.5

hod

Below are the descriptions of

the control methods, related

examination conducted with the

aim of identifying any anomalies or deviations

from normal conditions by means of visual checks.

Generally, the visual inspection is conducted

ssembling the equipment, unless there

are particular needs that may arise.

reference is made to

examinations such as penetrating liquids,

ultrasounds, magnetic particles, X

-rays, which may

be necessary after the visual examination

: concern tests carried out on

controls, levers, indicator screws, etc. Functional

tests are those that allow to obtain a value or a

OPERATIONAL TEST

: include tests with and

without load and/or tests for the functioning of the

s (with greater attention to the limiting

devices and indicators).

Loading...

Loading...