15

codice 09MAXX001

versione EN

revisione 01

Use and Maintenance Manual

MaxX

d) Insert the tool into the special hole and turn the

central hub until the threaded hole in which the

lever is to be screwed.

Fig.7.1D

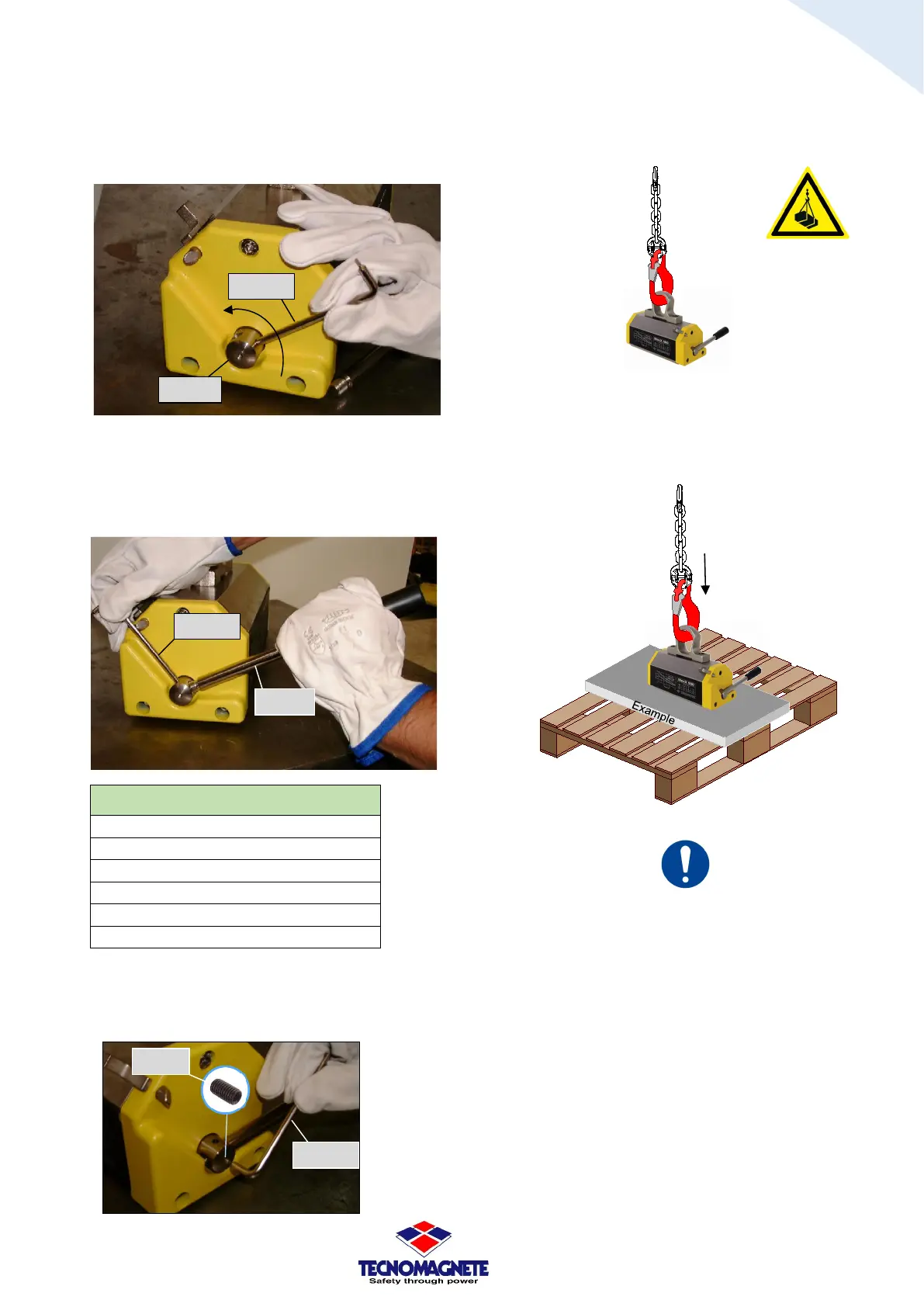

e) While keeping the hub in the position required in

phase d), tighten the lever in its threaded seat and

fasten it completely (Fig. 7.1E2 The lever tightening

values are shown).

Fig.7.1E1

Fig.7.1E2

Torque values for clamping the lever

MaxX 125/250/300E = 25 Nm

MaxX 500/600E = 48 Nm

MaxX 1000 = 85 Nm

MaxX 1500/2000 = 210 Nm

MaxX TG 150 = 25 Nm

MaxX TG 300 = 48 Nm

f) Insert the grub screw into the housing and tighten

it with the tool until the end of stroke to ensure

the locking of the Lever

Fig.7.1F

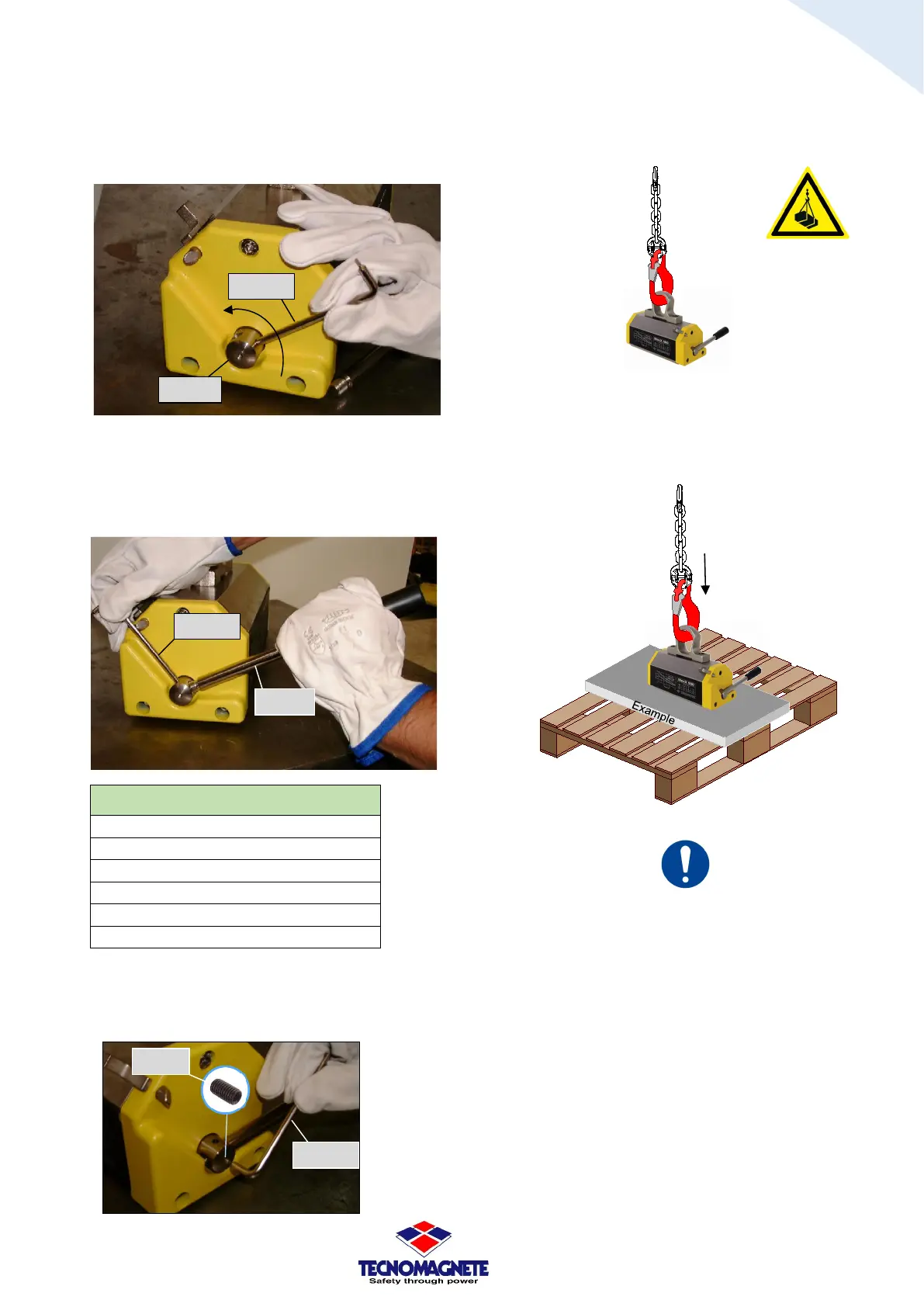

g) Handle MaxX with the same procedure described

in phase a)

Fig.7.1G

h) Place MaxX on the load to be handled and follow

the procedure described in chapter 9 as regards

the normal use of the equipment.

Fig.7.1H

MaxX is designed to be lifted and handled with suitable

lifting means (as described in paragraph 2.2), the type and

scope of which must be chosen in relation to the weights

of both the MaxX (see paragraph 5.2 table Fig. 5.2B) and

the addition of the load. It is important to periodically

check the structure of the MaxX with particular attention

to the eyebolt

/

load ring(see paragraph 10.12).

Loading...

Loading...