13

External wiring should be carried out in accordance with following requirement. Check and reassure the

wiring is correct after the wiring is complete.

(Do not utilize the control circuitry buzzer to check the wiring.)

EMI connections:

It is very important that the connections between the inverter, the shielded motor cable, and the EMI

filters are tested as follows.

z Use a metal grounding plate and place the frequency inverter and the EMI filter on the plate.

z Use a shielded motor cable with 4 connectors (U, V, W, & Earth), don’t use the shielding as safety

earth (shield is high frequency earth)

z Remove any paint around the two metal coupling nut holes. So that the metal coupling nuts (and

the shielding) make contact with the frequency inverter and the motor.

z Don't solder a conductor to the shielding.

z Use a metal clamp to connect the shielding from the motor cable with the metal grounding plate.

Now there is a perfect high frequency earth connection between frequency inverter, grounding

plate and EMI filter.

z Keep the distance between the frequency inverter and EMI filter as short as possible (< 30cm) if

longer use a shielded cable with a metal coupling nut and a metal clamp to connect the shielded

cable to the frequency inverter and metal grounding plate.

z The only earth connection between the LISN and the test plate should be via the EMI filter.

z Use a motor which equals the power rating or below of the inverter rating.

z Install a noise filter for inverter onto the output side of the primary circuitry can suppress

conducting noise.

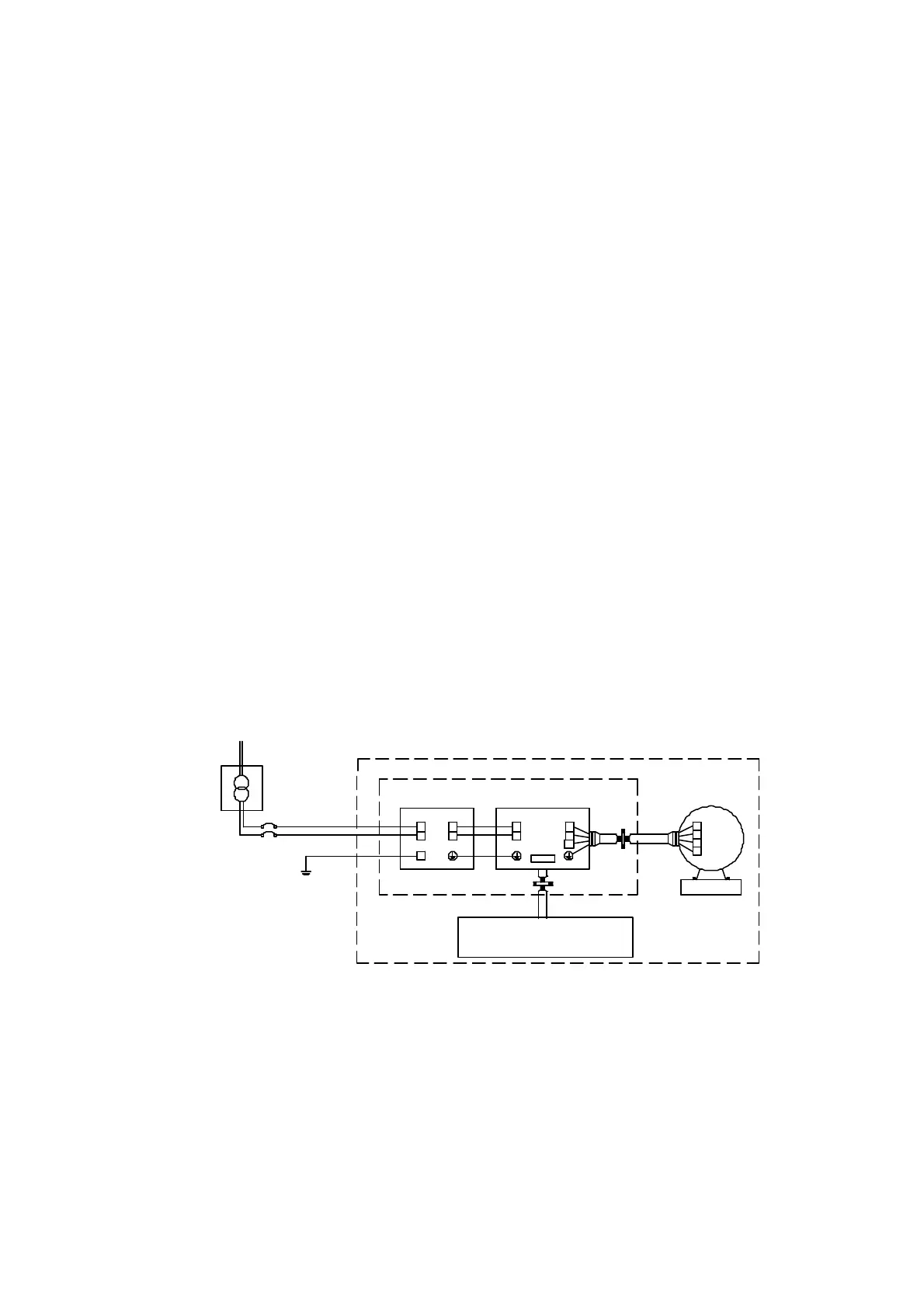

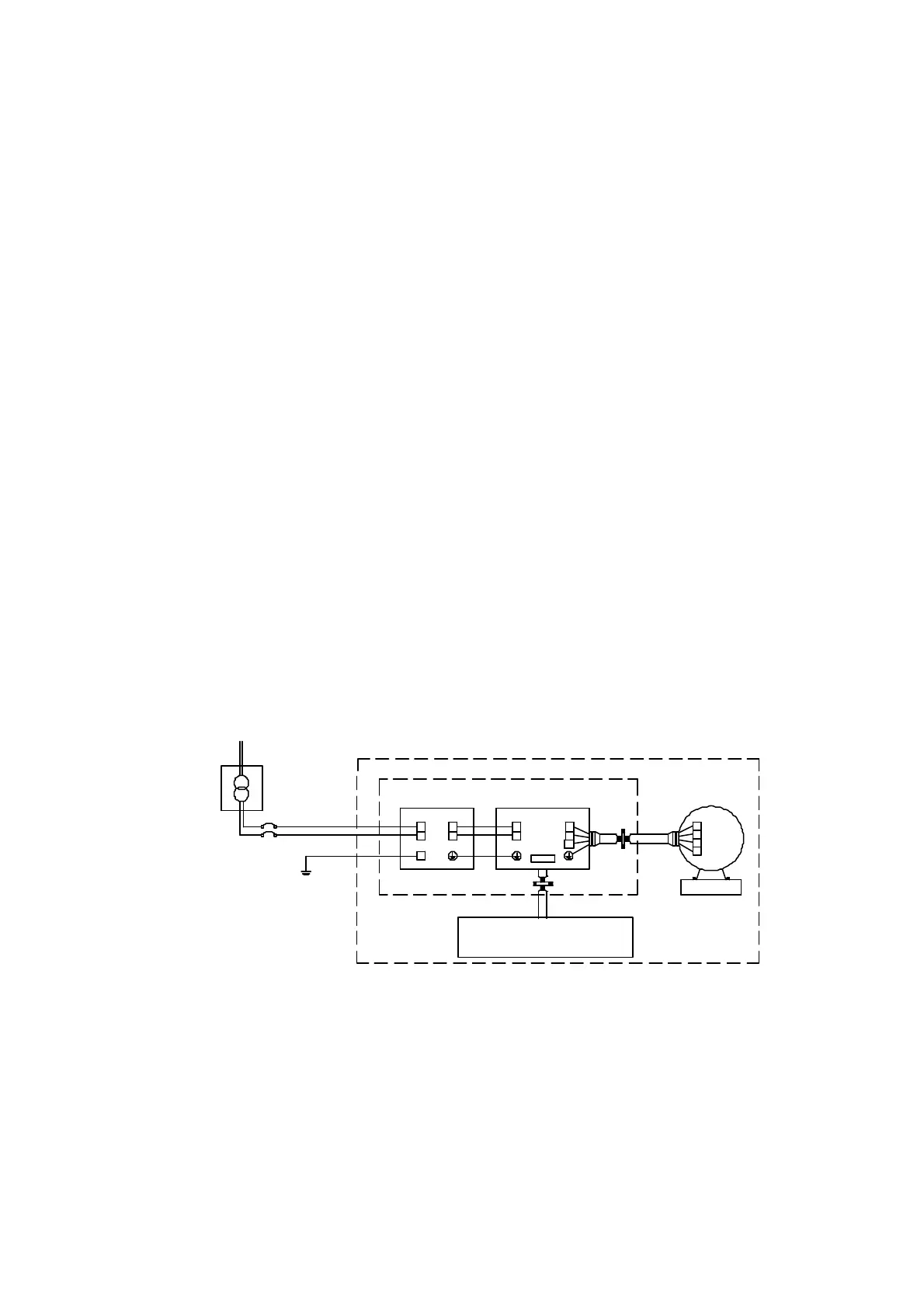

Remote control switches,

relay or similar equipm ents

Power Supply

Power Drive System(PDS)

Metal plate or panel

EMI FILTER

Power Port

Main Transform er

3ΦIM

M

L

NN

LL1

L2

TM2

T1

T2

T3

U

V

W

G

MC C B

Drive

Class B:

Loading...

Loading...