Maintenance

2

TLA7000 Series Mainframe Technical Reference Manual

Inspection and Cleaning

The instrument is inspected mechanically and electrically before shipment. It

should be free of marks or scratches and should meet or exceed all electrical

specifications. To confirm this, inspect for physical damage incurred during

transit. Retain the packaging in case shipment for repair is necessary. If there is

damage or deficiency, contact your local Tektronix representative.

Cleaning procedures consist of exterior and interior cleaning. Periodic cleaning

reduces instrument breakdown and increases reliability. Clean the instrument as

needed, based on your operating environment.

Inspect the outside of the instrument for damage, wear, and missing parts. Use

Table 1 as a guide. Modules that appear to have been dropped or otherwise

abused should be checked thoroughly to verify correct operation and perfor-

mance. Immediately repair defects that could cause personal injury or lead to

further damage to the benchtop controller, expansion module, or the mainframes

that the module plug into.

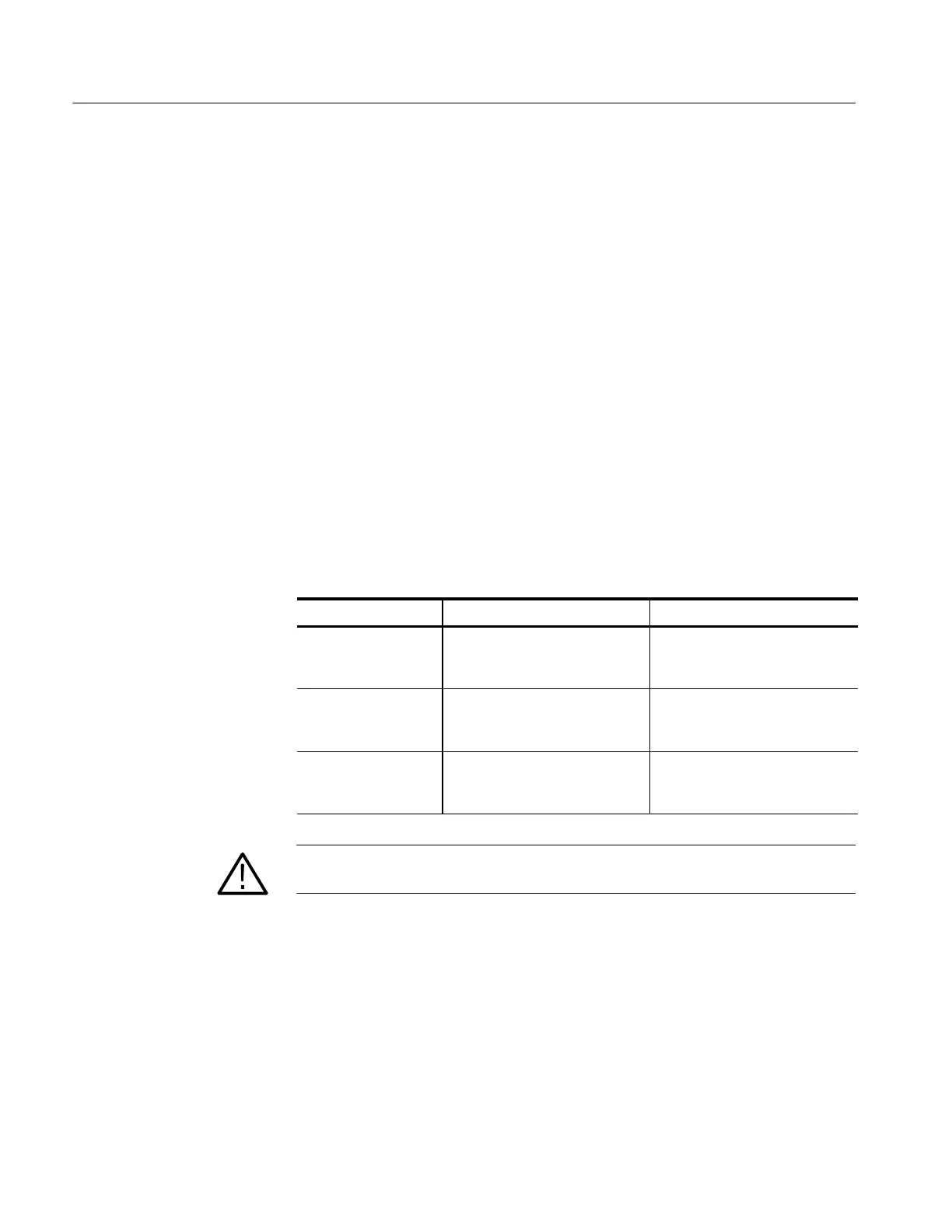

Table 1: External inspection check list

Item Inspect for Repair action

Front panel Cracks, scratches, deformations,

missing or damaged retainer

screws, or ejector handles.

Replace defect ive or missing

parts.

Front and rear connec-

tors

Broken shel ls, cracked insulation,

and deformed contacts. Dirt in

connectors.

Replace defect ive parts. Clear dirt

out of connectors.

Accessories Missing items or parts of items,

bent pins, broken or frayed

cables, and damaged connectors.

Replace damaged or missing

parts, frayed cables.

CAUTION. To prevent damage to electrical components from moisture during

external cleaning, use only enough liquid to dampen the cloth or applicator.

Exterior Inspection

Loading...

Loading...