Do you have a question about the Tektronix AA 501 and is the answer not in the manual?

Defines terms like CAUTION, WARNING, DANGER and explains symbols.

Covers hazards related to power source, grounding, fuses, explosive atmospheres, and covers.

Outlines safety rules for service personnel, including not working alone and handling live circuits.

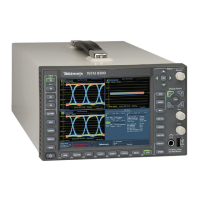

Details the AA 501's capabilities, features, and measurement types.

Specifies environmental requirements and warm-up times for instrument accuracy.

Steps for installing and preparing the AA 501 for operation.

Instructions for properly packaging the instrument for shipping or service.

Describes the front panel controls, connectors, and indicators for operating the AA 501.

Explains connections for auxiliary input, ground, LED bar graph, digital display, and instrument interface.

Illustrates the typical setup for performing distortion measurements.

Details how the AA 501 functions as an AC voltmeter in the Level function.

Explains the principles and methods of measuring signal distortion.

Outlines the steps for performing distortion measurements, including manual and automatic modes.

Explains intermodulation distortion measurement and Option 01 capabilities.

Describes the function and application of the built-in frequency weighting filters.

Details the two display modes: digital readout and LED bar graph.

Explains how interface capabilities aid in measurement interpretation.

Provides an overview of the AA 501's operational blocks and circuit descriptions.

Describes the low-noise input amplifier design and gain control circuitry.

Explains the function and components of the automatic gain control circuit.

Details the operation and tuning of the notch filter circuit.

Explains how the instrument detects and discriminates frequency bands.

Describes the control loop for the notch filter tuning.

Explains the distortion amplifier's role in amplifying distortion signals.

Details the weighting filters and AC/DC conversion methods.

Explains the circuitry for converting measured values to dB.

Describes the function of the dB offset generator.

Explains how to set a 0 dB reference for ratio measurements.

Describes the 6V reference voltage source.

Explains the operation of the digital voltmeter display.

Describes the logic control for input stage and distortion amplifier gain.

Further details on logic control for decimal points and distortion amplifier gain.

Describes the +5V, +15V, and -15V power supplies used in the instrument.

Details the -15V supply regulation and protection.

Provides a block diagram for the intermodulation distortion option.

Outlines the procedure for verifying electrical performance requirements.

Lists the essential test equipment for calibration and adjustment.

Lists all performance checks and internal adjustments required.

Details specific tests to verify instrument performance.

Details specific steps for internal instrument adjustments.

Procedure to verify the instrument's input impedance.

Procedure to verify the instrument's common mode rejection capability.

Procedure to verify the accuracy of the level measurement function.

Procedure to verify the instrument's frequency response bandwidth.

Procedure to measure the instrument's residual noise level.

Procedure to verify the accuracy of total harmonic distortion measurements.

Procedure to check residual IM distortion for SMPTE/DIN modes.

Procedure to check residual IM distortion for CCIF mode.

Procedure to verify IM distortion accuracy for SMPTE tests.

Procedure to verify IM distortion accuracy for CCIF difference tone tests.

An alternative procedure for checking CCIF IM distortion accuracy.

Procedure to verify the accuracy of the instrument's filters.

Procedure to verify the functionality of the input monitor.

Procedure to verify the functionality of the function output.

Procedure to verify the functionality of the auxiliary input.

Explains when and why internal adjustments are necessary.

Information on obtaining instrument repair and adjustment services.

Lists the required test equipment for performing internal adjustments.

Procedure for adjusting the distortion amplifier offset.

Procedure for adjusting the RMS and Average zero points.

Procedure for calibrating voltage and average readings.

Procedure for adjusting attenuation compensation.

Procedure for adjusting 0 dB, -20 dB, and input zero points.

Procedure for adjusting the offset gain.

Procedure for adjusting the dBr zero point.

Procedures for adjusting null, frequency trim, and third harmonic null.

Procedure for adjusting distortion calibration.

Procedure for calibrating SMPTE measurements for Option 01.

Procedure for calibrating difference frequency for Option 01.

An alternative procedure for calibrating difference frequency.

General guidelines and precautions for maintaining the instrument.

Precautions for handling components susceptible to static discharge damage.

Information on how to obtain electrical and mechanical replacement parts.

Proper soldering techniques required for instrument maintenance and repair.

Procedures for safely handling and removing semiconductors, pins, cables, assemblies, connectors, and latches.

Steps for accessing and removing circuit boards, including covers and latches.

Information regarding the magnetic shield's properties and handling.

Instructions on configuring jumpers for different measurement modes.

Details on modifying the 30 kHz low pass filter's characteristics.

General description of the rear panel connectors and their functions.

Details on rear interface connectors for input, output, and monitor signals.

Information on SMPTE HF Output, Converter Output, and dB Converter Output connectors.

Guidelines for ordering parts, including required information and special notes.

Explanation of the organization and fields within the electrical parts list.

A cross-reference of manufacturer codes to their names and addresses.

Explains the graphic symbols, class designation letters, and logic symbology used.

Explains how assemblies and component locations are identified and referenced.

A block diagram illustrating the overall signal flow and functional units of the AA 501.

Illustration showing adjustment points and jumper locations on control and IMD option boards.

Illustration showing adjustment points on the Option 02 main board.

Illustration showing adjustment points on main, input, notch, and DVM boards.

A grid showing the physical locations of components on the Input Board (A14 Assy).

Information on ordering mechanical parts, including required information and special notes.

Explanation of the organization and fields within the mechanical parts list.

A cross-reference of manufacturer codes to their names and addresses for mechanical parts.

A specific correction to the text of the manual.

Lists modifications and updates to the Operating Instructions section.

Provides response curves for the AA 501 filters, including CCIR WTG and 22.4 Hz filters.

Clarifies filter usage and circuitry details for Option 02 instruments.

Lists updates and additions to the Suggested Test Equipment table.

Details changes made to the Performance Check Steps on page 4-3.

Details changes made to the Adjustment Procedure Steps on page 4-3.

Lists updates and additions to performance check procedures on pages 4-6, 4-7, and 4-8.

Details updates and changes to calibration procedures on pages 4-10, 4-11, and 4-12.

Lists modifications to calibration steps 11, 11A, 12c, 12j, 12q, and 12r.

Details updates to the filter response checks, including steps x through rr.

Details updates to adjustment procedures including adding steps and modifying existing ones.

Details updates to calibration procedures, including adding and modifying steps for various tests.

Explains the filter options available for Option 02 instruments.

| Type | Audio Analyzer |

|---|---|

| Frequency Range | 10 Hz to 100 kHz |

| Input Impedance | 100 kΩ |

| Output Impedance | 600 Ω |

| Signal-to-Noise Ratio | 90 dB |

Loading...

Loading...