ME910G1 HW Design Guide

1VV0301593 Rev.3 Page 75 of 97 2020-03-24

In order to easily rework the ME910G1 is suggested to consider on the application a 1.5

mm placement inhibit area around the module.

It is also suggested, as common rule for an SMT component, to avoid having a

mechanical part of the application in direct contact with the module.

NOTE:

In the customer application, the region under WIRING INHIBIT (see

figure above) must be clear from signal or ground paths.

PCB pad design

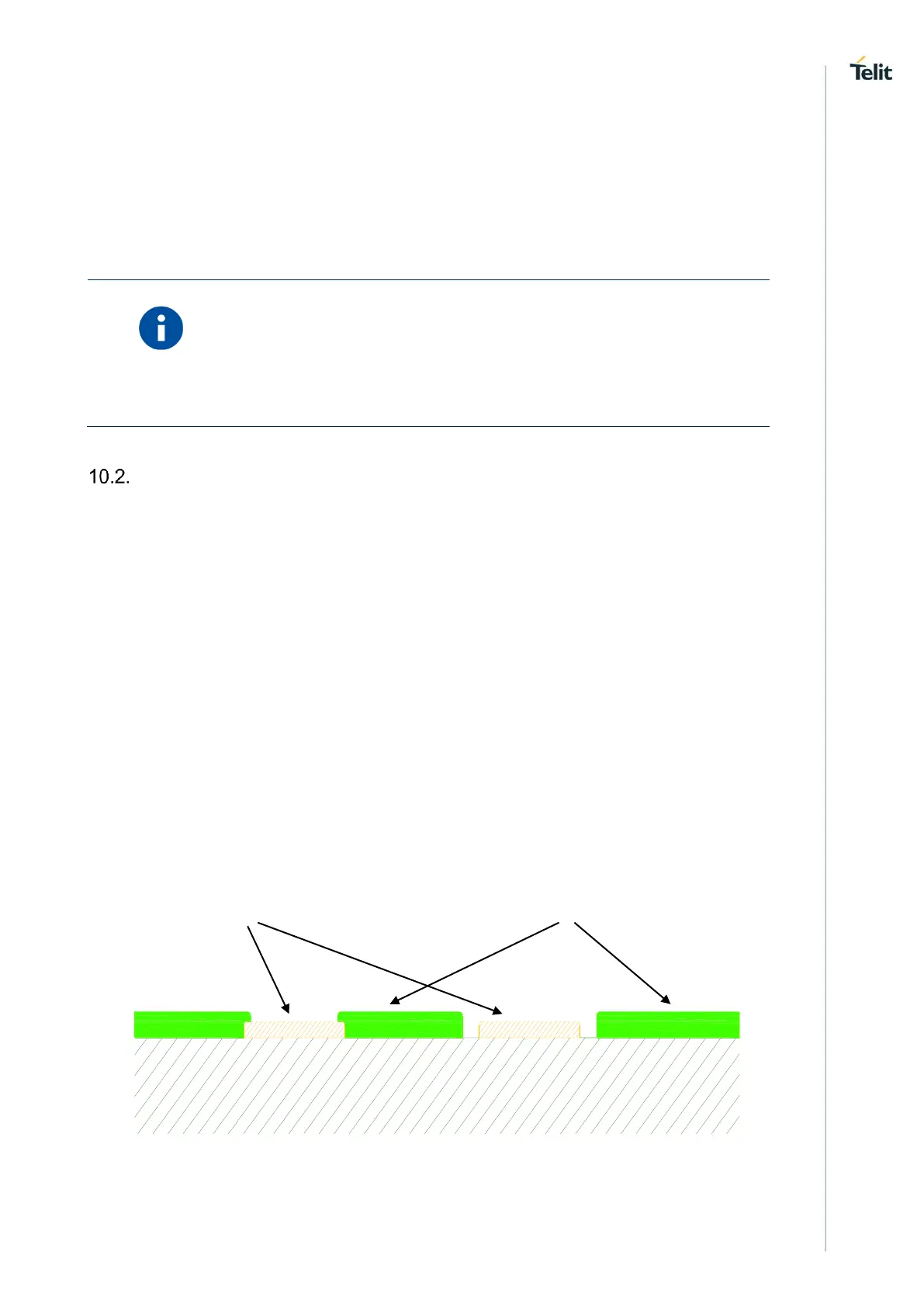

In PCB design, the solder pads can be defined as either Solder Mask Defined (SMD) or

Non-Solder Mask Defined (NSMD). The difference between these two solder mask pad

definitions, is in the closeness of the solder mask to the metal pad. In SMD pads, the

solder mask opening is smaller than the metal pad and overlaps the metal on all sides.

The solder mask opening defines the solderable area of the pad. In NSMD pads, the

solder mask opening is larger than the metal pad and does not overlap the metal. The

metal edge defines the solderable area of the pad (see Figure below).

Since the metal etching process in PCB manufacture, has significantly tighter alignment

and etch tolerances than the alignment registration of the solder masking process, which,

a more accurate solder pad land pattern can be obtained with NSMD pads. In addition,

with SMD pads, the solder mask that overlaps the metal pad introduces additional height

above the metal surface that may affect solder joint adhesion and reliability.

Non solder mask defined (NSMD) type is recommended for the solder pads on the PCB.

Loading...

Loading...