Section 3 • Scheduled Maintenance Procedures

3 - 6 RL4000 • TML-4000 Part No. 116694

June 2013

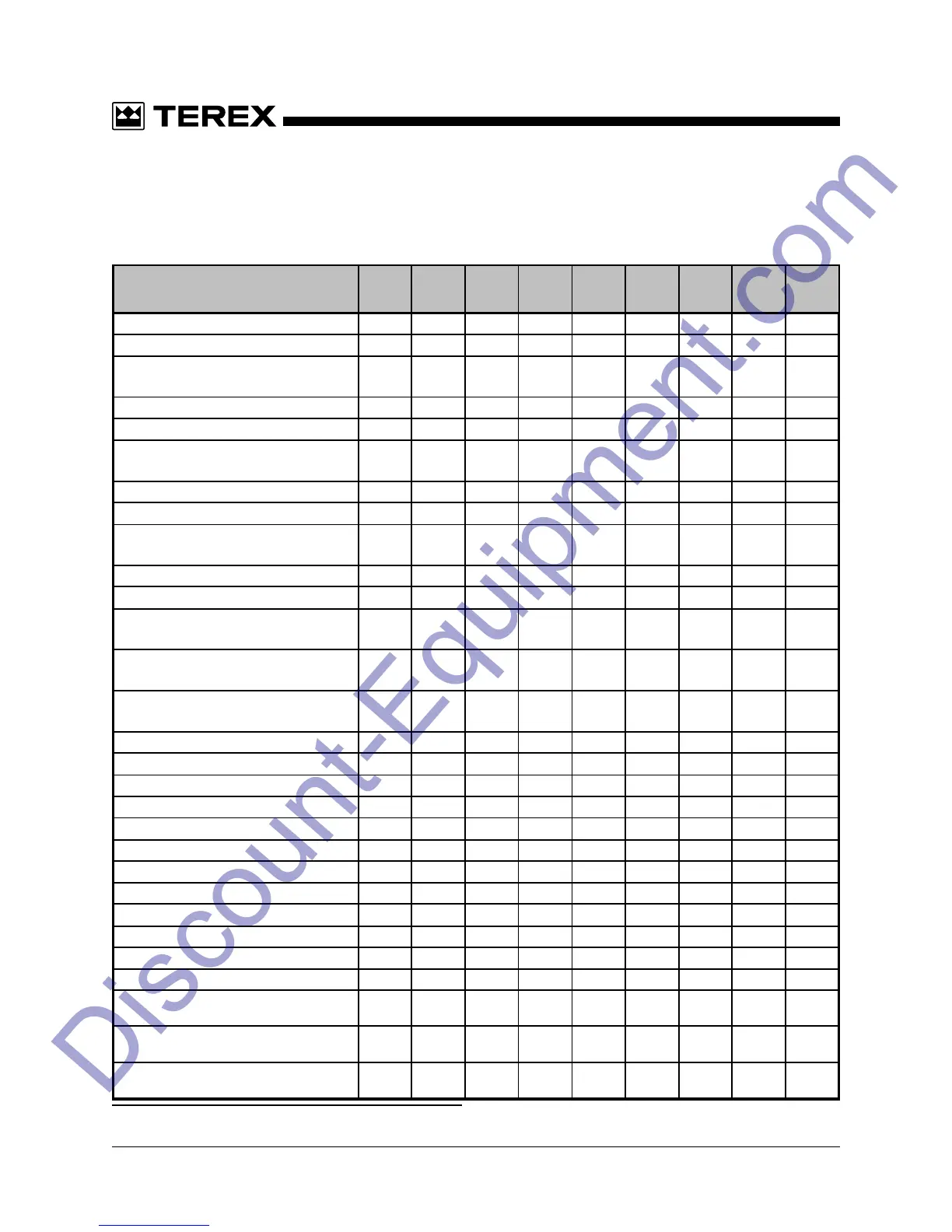

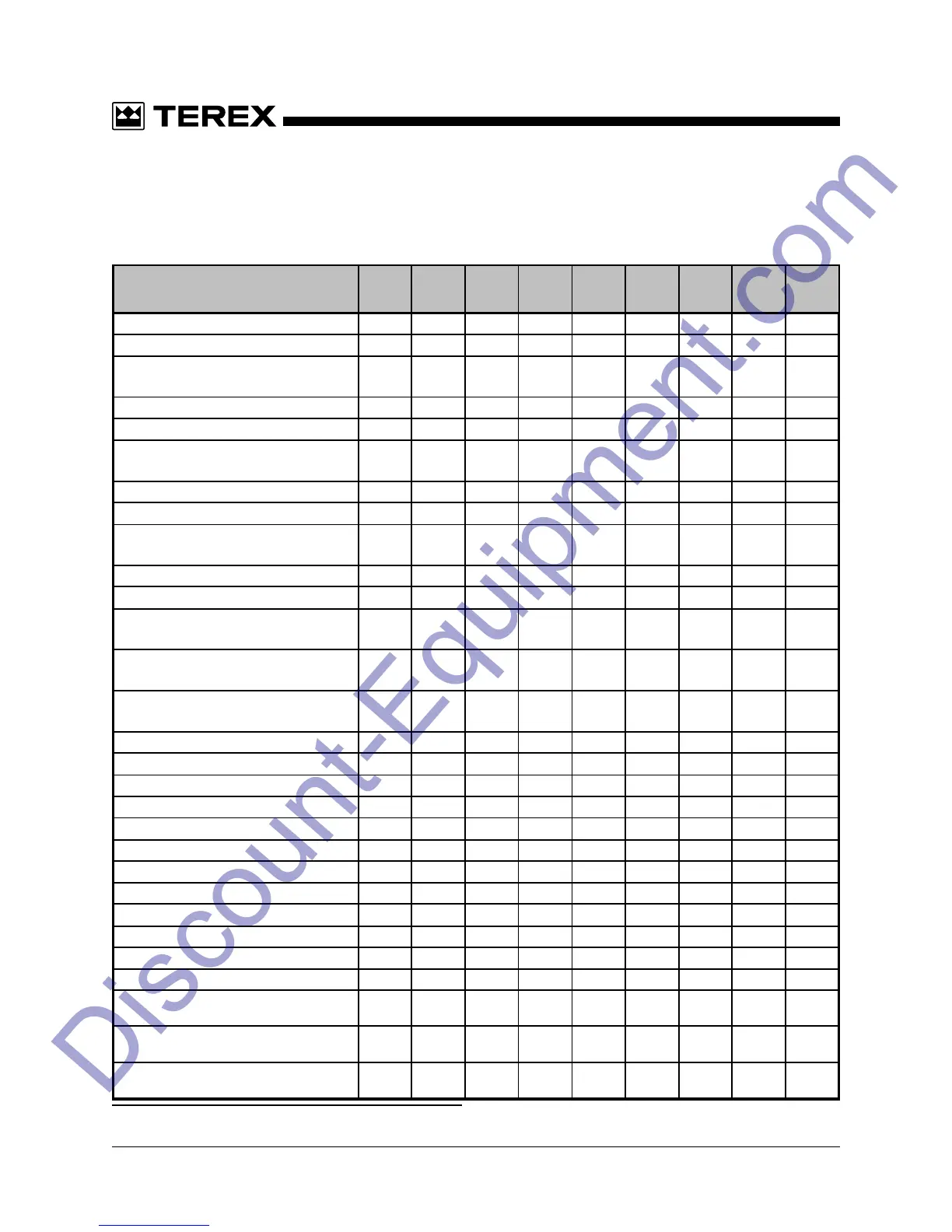

MAINTENANCE SCHEDULES CONTINUED

ITEM

Daily

Every 50

Hours

Every

250

Hours

Every

500

Hours

Every

1000

Hours

Every

2000

Hours

Every

3000

Hours

Every

6000

Hours

Every

12000

Hours

Cooling system coolant level - check

•

Driven equipment - check

•

Engine air cleaner service indicator -

inspect

•

Engine air precleaner - check/clean

•

Engine oil level - check

•

Fuel system primary filter/water

separator - drain

•

Walk around inspection

•

Fuel tank water and sediment - drain

•

Alternator and fan belts -

inspect/adjust

•

Fuel system filter - replace

•

Battery electrolyte level - check

•

Cooling system supplemental coolant

additive (SCA) - test/add

•

Engine air cleaner element (dual

element) - clean/replace

•

Engine air cleaner element (single

element) - inspect/replace

•

Engine oil and filter - change

•

Hoses and clamps- inspect/replace

•

Radiator - clean

•

Alternator and fan belts - replace

•

Engine valve lash - inspect/adjust

•

Turbocharger - inspect

•

Alternator - inspect

•

Engine crankcase breather - replace

•

Engine mounts - inspect

•

Starter motor - inspect

•

Fuel injector - test/change

•

Water pump - inspect

•

Cooling system coolant (commercial

heavy-duty) - change

•

Cooling system coolant extender

(ELC) - add

•

oo

ng sys

em coo

an

-

change

•

Perkins Lubrication and Maintenance Service Intervals

Perkins Operations Manual

Loading...

Loading...