a multi-master scenario can be avoided. This allows breaking the connection between the I

2

C channels and the

system to allow I

2

C access to the TPS65982 from an external tool. A header is used to allow for connections

without soldering; however, SMT test pads can be used to provide a place to solder blue-wires for testing.

Exposing the SWD_DATA and SWD_CLK pins will allow for more advanced debugging if needed. A header or

SMT test point is also used for the SWD_DATA and SWD_CLK pins.

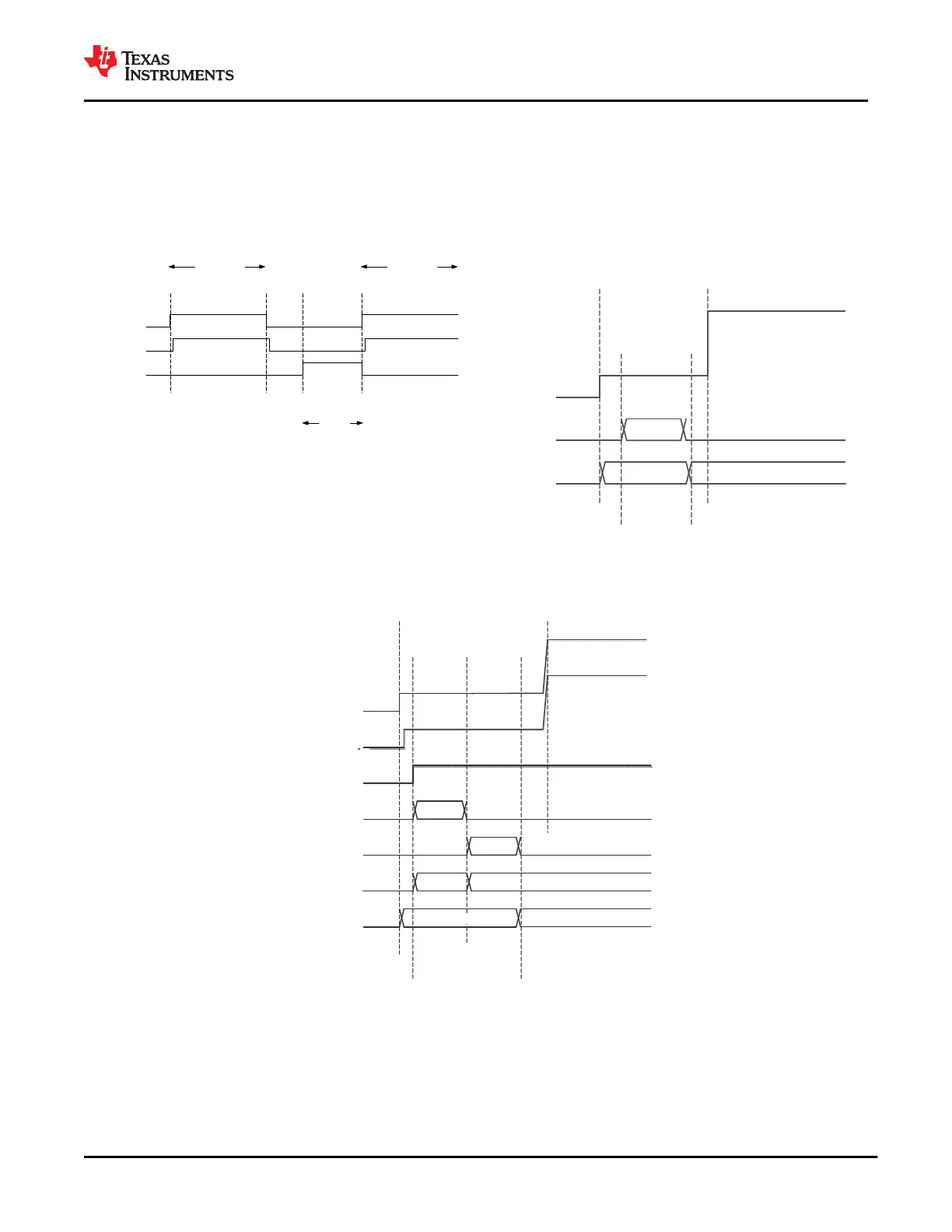

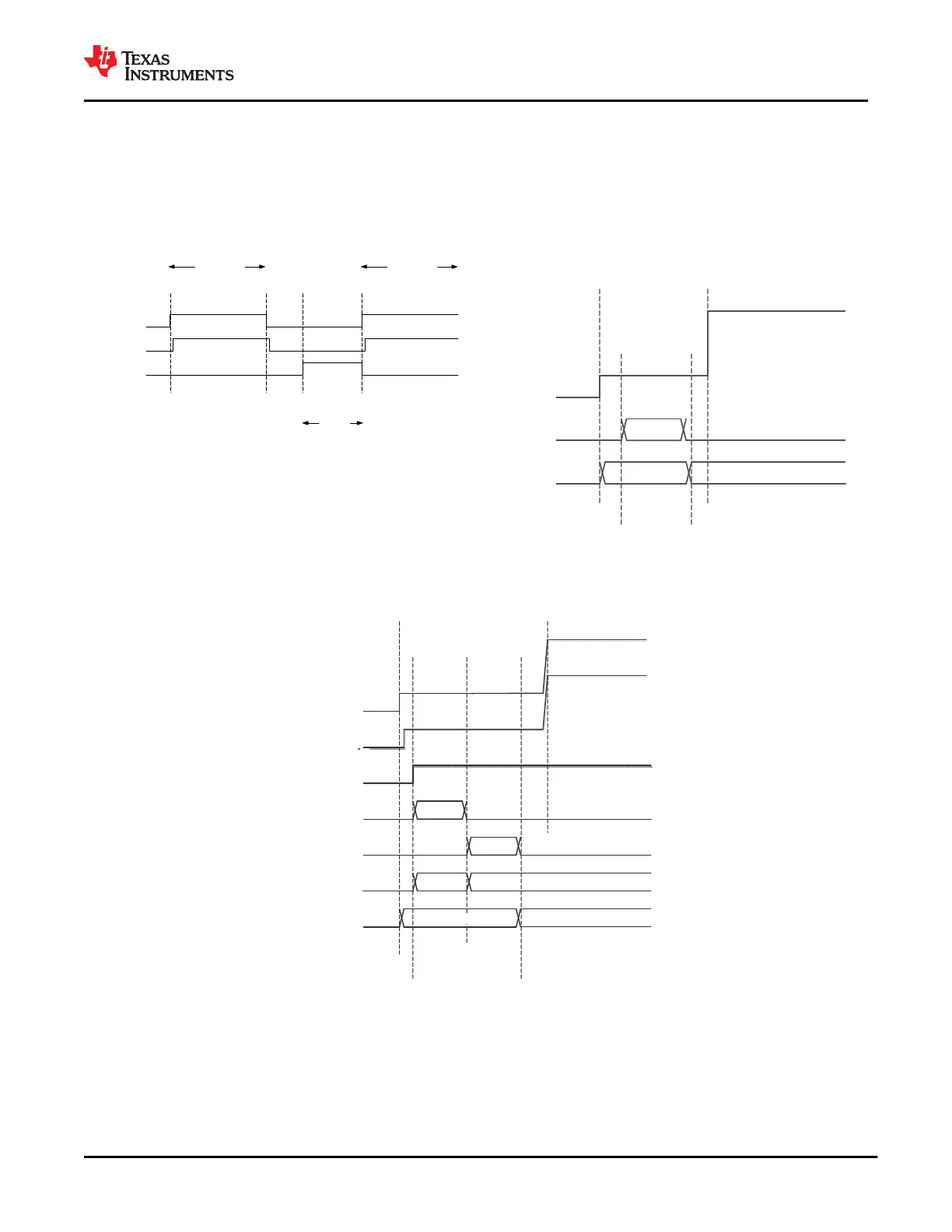

10.2.2.3 Application Curves

DC Barrel Jack

Attached

DC Barrel Jack

Detect/PFET Enable

Type-C

Charging

Barrel Jack

Inserted

Barrel Jack

Removed

Enter 20 V Type-C

PD Contract

Barrel Jack

Inserted

Exit 20 V Type-C

PD Contract

Barrel Jack Charging Barrel Jack Charging

PD Charging

Figure 10-7. DC Barrel Jack and Type-C PD

Charging Hand-Off

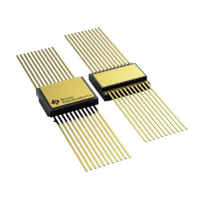

Type-C Cable

Connected

Flash FW

Load Start

Boot

Application

Load

PD Comm.

Enabled

20 V PD Power

Contract

VBUS

Application

FW Load

Active

TPS65982 Code

0 V

5 V

20 V

Figure 10-8. Primary TPS65982 Dead Battery

Sequence

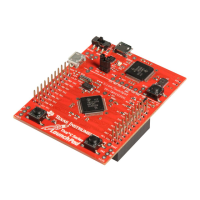

Type-C Cable

Connected

SPI LOAD

Primary

TPS65982 Loads

App. FW (SPI)

20 V PD Power

Contract

Secondary

VBUS

Primary

Application

FW Load

Primary Active

TPS65982 Code

0 V

5 V

20 V

Secondary

PP_EXT

0 V

5 V

BQ Charger

3.3 V Auxiliary

(VIN_3V 3)

0 V

3.3 V

UART LOAD

Secondary

Application

FW Load

Secondary Active

TPS65982 Code

Secondary

TPS65982 Loads

App. FW (UART)

Secondary PD

Communication

Enabled

20 V

Boot

Application

Boot

Application

Figure 10-9. Secondary TPS65982 Dead Battery Sequence

www.ti.com

TPS65982

SLVSD02E – MARCH 2015 – REVISED AUGUST 2021

Copyright © 2021 Texas Instruments Incorporated

Submit Document Feedback

89

Product Folder Links: TPS65982

Loading...

Loading...