CUTMASTER A120

OPERATION 4T-4 Manual 0-4989

Bottom Dross Buildup

Molten material which is not blown out of the

cut area and resolidifies on the plate. Excessive

dross may require secondary cleanup opera-

tions after cutting.

Kerf Width

The width of the cut (or the width of material

removed during the cut).

Top Spatter (Dross)

Top spatter or dross on the top of the cut caused

by slow travel speed, excess cutting height, or

cutting tip whose orifice has become elongated.

4T.05 General Cutting Information

!

WARNING

Disconnect primary power at the source be-

fore disassembling the power supply, torch,

or torch leads.

Frequently review the Important Safety Pre-

cautions at the front of this manual. Be sure

the operator is equipped with proper gloves,

clothing, eye and ear protection. Make sure no

part of the operator’s body comes into contact

with the workpiece while the torch is activated.

CAUTION

Sparks from the cutting process can cause

damage to coated, painted, and other surfac-

es such as glass, plastic and metal.

NOTE

Handle torch leads with care and protect

them from damage.

Piloting

Piloting is harder on parts life than actual cut-

ting because the pilot arc is directed from the

electrode to the tip rather than to a workpiece.

Whenever possible, avoid excessive pilot arc

time to improve parts life.

Torch Standoff

Improper standoff (the distance between the

torch tip and workpiece) can adversely affect

tip life as well as shield cup life. Standoff may

also significantly affect the bevel angle. Re-

ducing standoff will generally result in a more

square cut.

Edge Starting

For edge starts, hold the torch perpendicular to

the workpiece with the front of the tip near (not

touching) the edge of the workpiece at the point

where the cut is to start. When starting at the

edge of the plate, do not pause at the edge and

force the arc to "reach" for the edge of the metal.

Establish the cutting arc as quickly as possible.

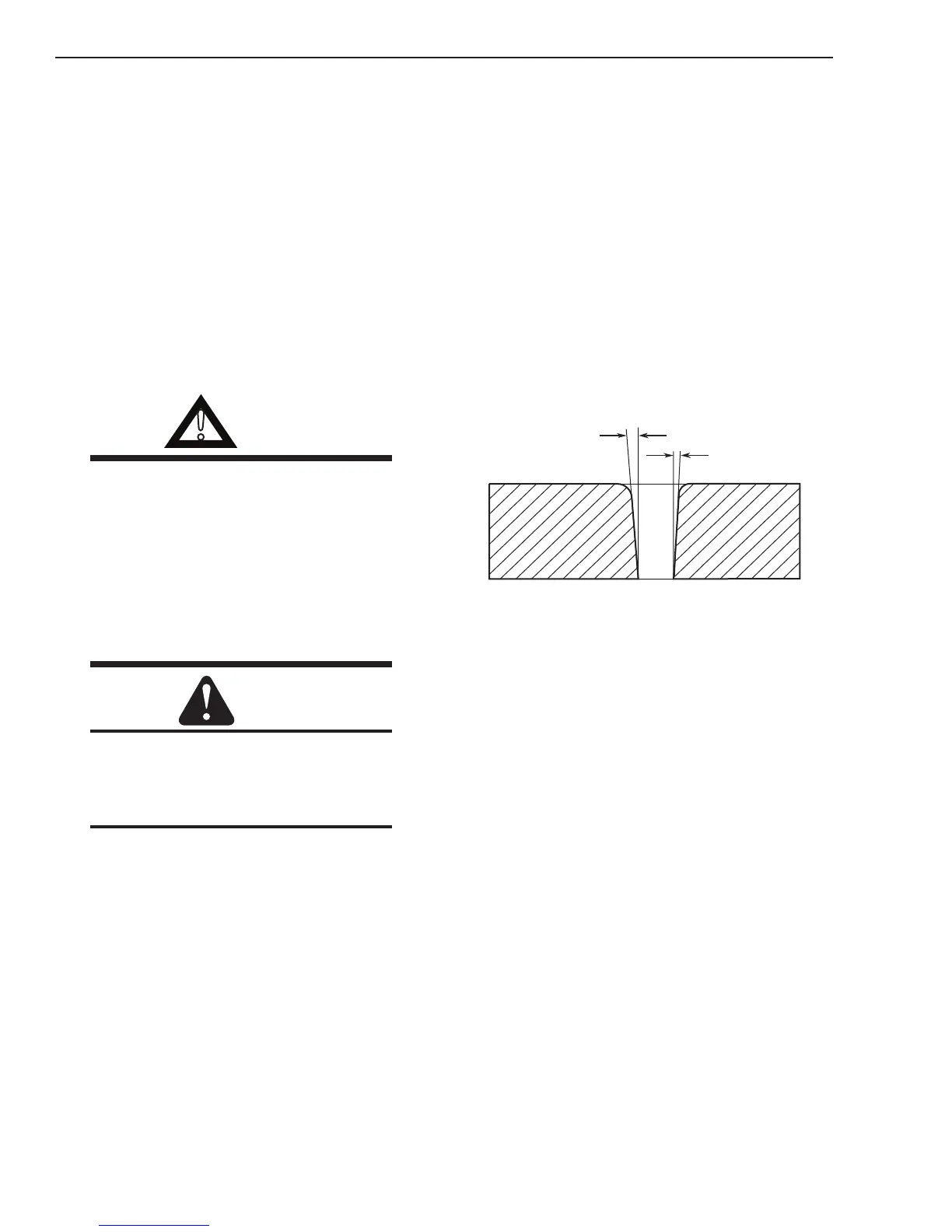

Direction of Cut

In the torches, the plasma gas stream swirls as

it leaves the torch to maintain a smooth column

of gas. This swirl effect results in one side of a

cut being more square than the other. Viewed

along the direction of travel, the right side of

the cut is more square than the left.

Right Side

Cut Angle

Cut Angle

A-00512

Side Characteristics Of Cut

To make a square - edged cut along an inside

diameter of a circle, the torch should move

counterclockwise around the circle. To keep

the square edge along an outside diameter cut,

the torch should travel in a clockwise direction.

Dross

When dross is present on carbon steel, it is com-

monly referred to as either “high speed, slow

speed, or top dross”. Dross present on top of

the plate is normally caused by too great a torch

to plate distance. "Top dross" is normally very

easy to remove and can often be wiped off with

a welding glove. "Slow speed dross" is normally

present on the bottom edge of the plate. It can

vary from a light to heavy bead, but does not

adhere tightly to the cut edge, and can be easily

scraped off. "High speed dross" usually forms

a narrow bead along the bottom of the cut edge

and is very difficult to remove. When cutting

a troublesome steel, it is sometimes useful to

reduce the cutting speed to produce "slow speed

dross". Any resultant cleanup can be accom-

plished by scraping, not grinding.

Loading...

Loading...