Structural Maintenance

125

Fanshaft Assembly

The unit is equipped with a one-piece fanshaft

assembly that contains tapered roller bearings in a

sealed oil reservoir. This assembly does not

require any maintenance. There is a level plug and

a fill plug, but they are not normally utilized

except after removal and repair of the fanshaft

assembly. The condenser end oil seal and the

evaporator end oil seal should be checked during

the pretrip inspection for oil leakage. If there is

any sign of leakage, the fanshaft assembly should

be removed and repaired.

NOTE: The fanshaft assembly requires a special

lubricant (see Tool Catalog).

Disassembly

1. Remove the fanshaft assembly from the unit.

Remove both oil plugs and drain the oil from

the housing.

2. After draining the oil from the housing,

remove the four retaining bolts from the

bearing retainer cap.

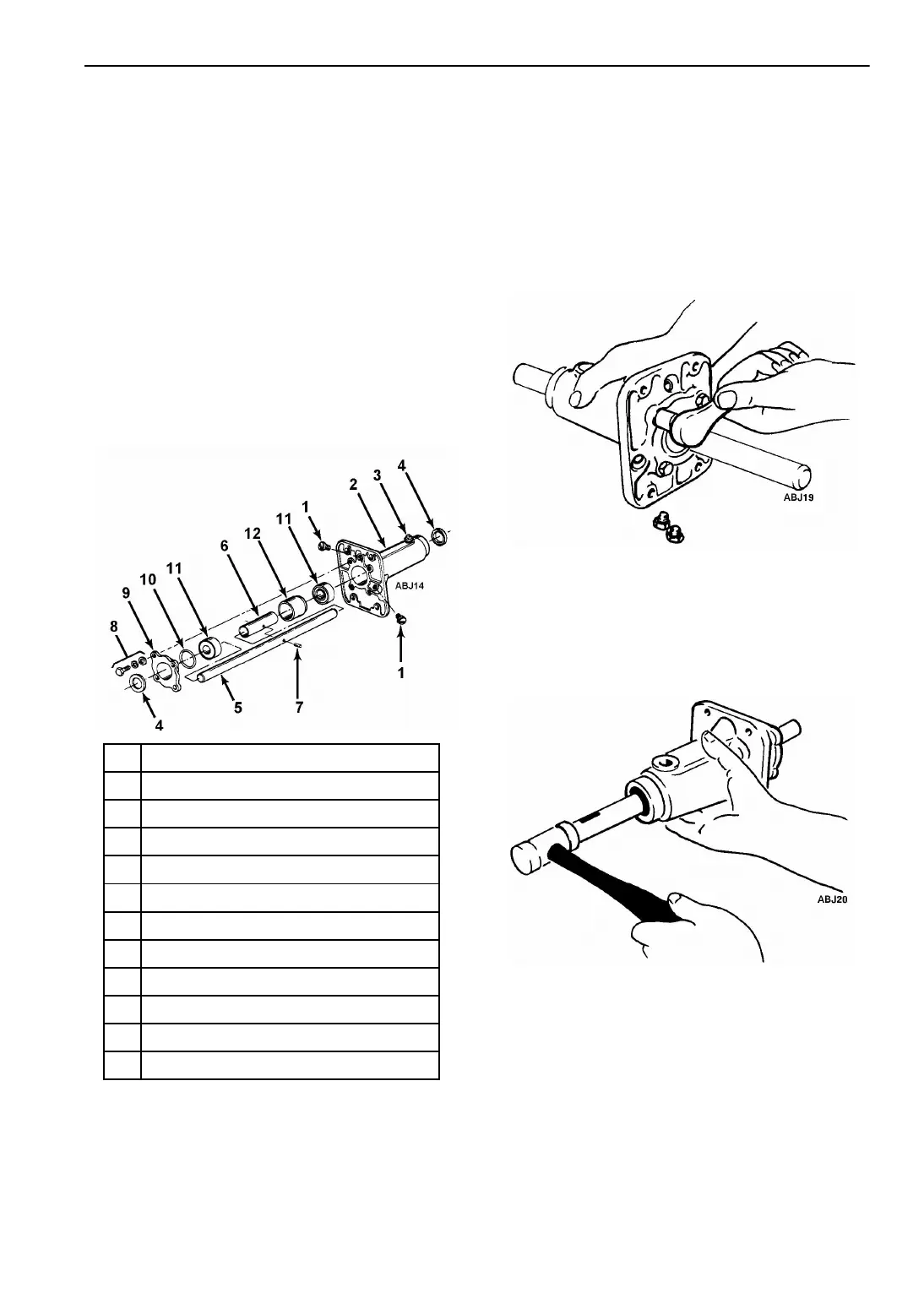

Figure 81: Removing Bearing Retainer Bolts

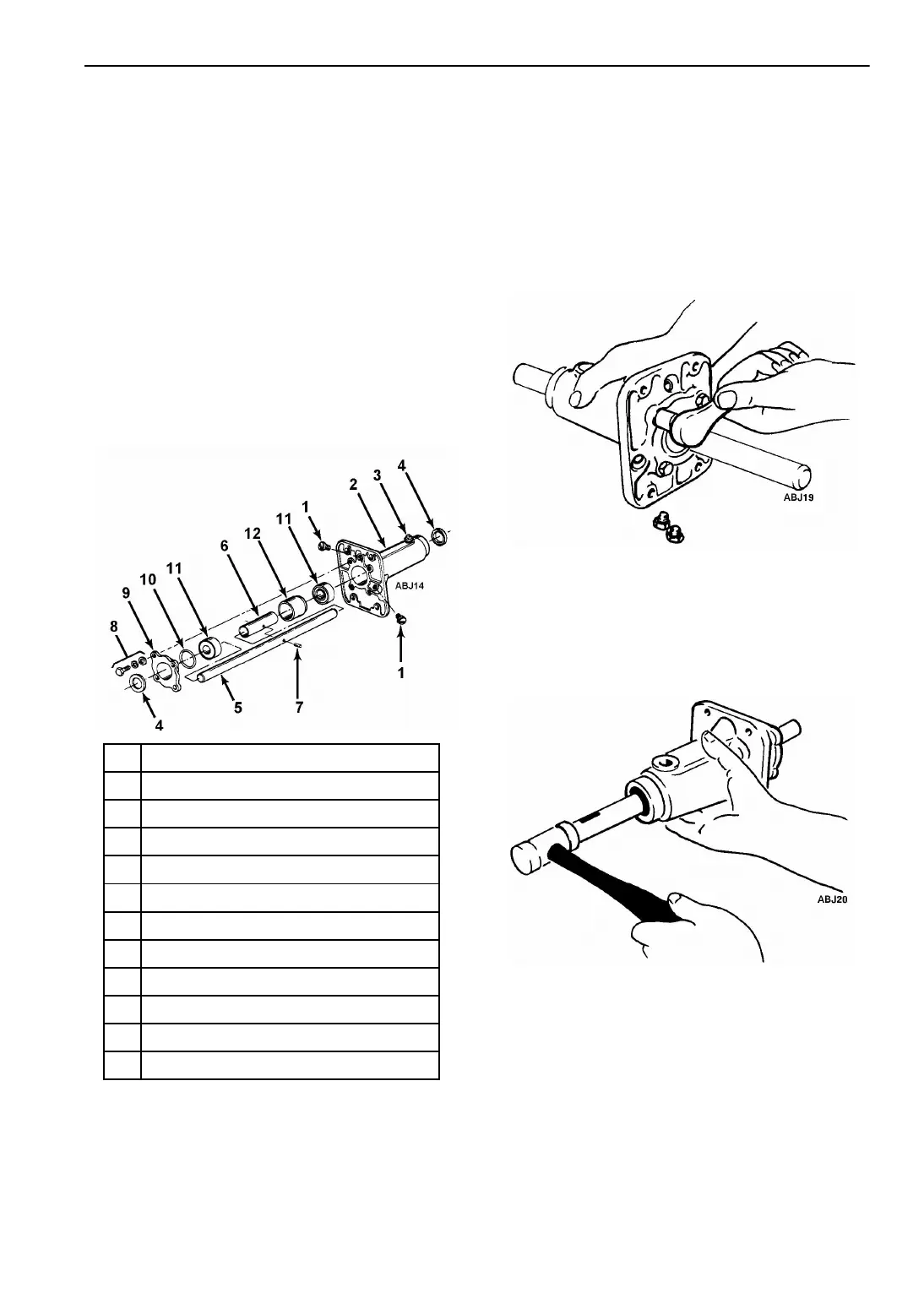

3. To remove the shaft from the assembly, tap the

opposite end of the shaft with a soft hammer.

After the shaft has been removed, clean all

parts in clean solvent.

Figure 82: Removing Shaft

1. Oil Plug Screw with O-ring

2. Housing

3. Breather Vent

4. Oil Seal

5. Shaft

6. Sleeve

7. Pin

8. Screw with Flatwasher and Lockwasher

9. Cap and Shims

10. O-ring

11. Roller Bearing

12. Splash Guard Tube

Figure 80: Fan Shaft Assembly

Loading...

Loading...