Engine Maintenance

81

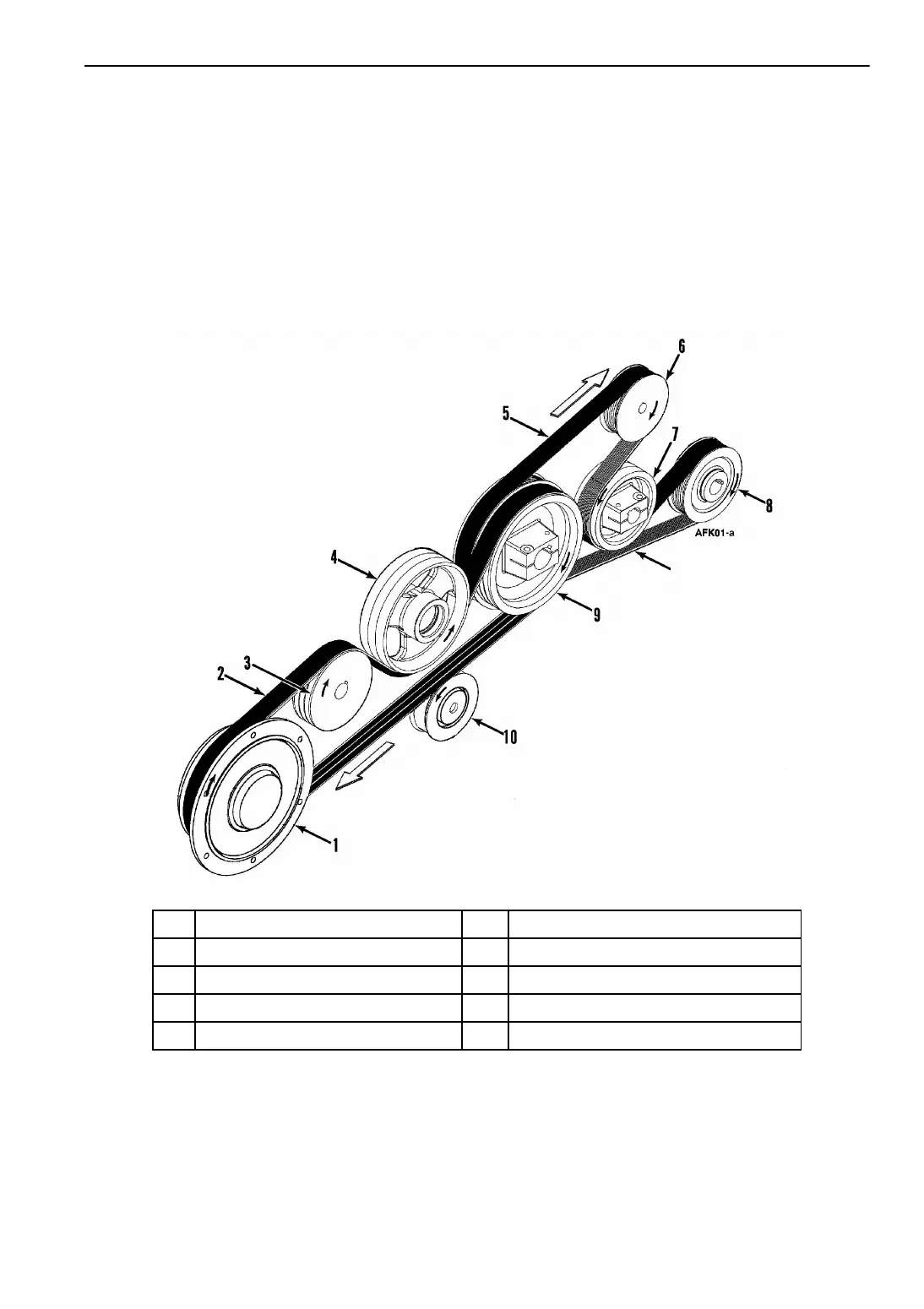

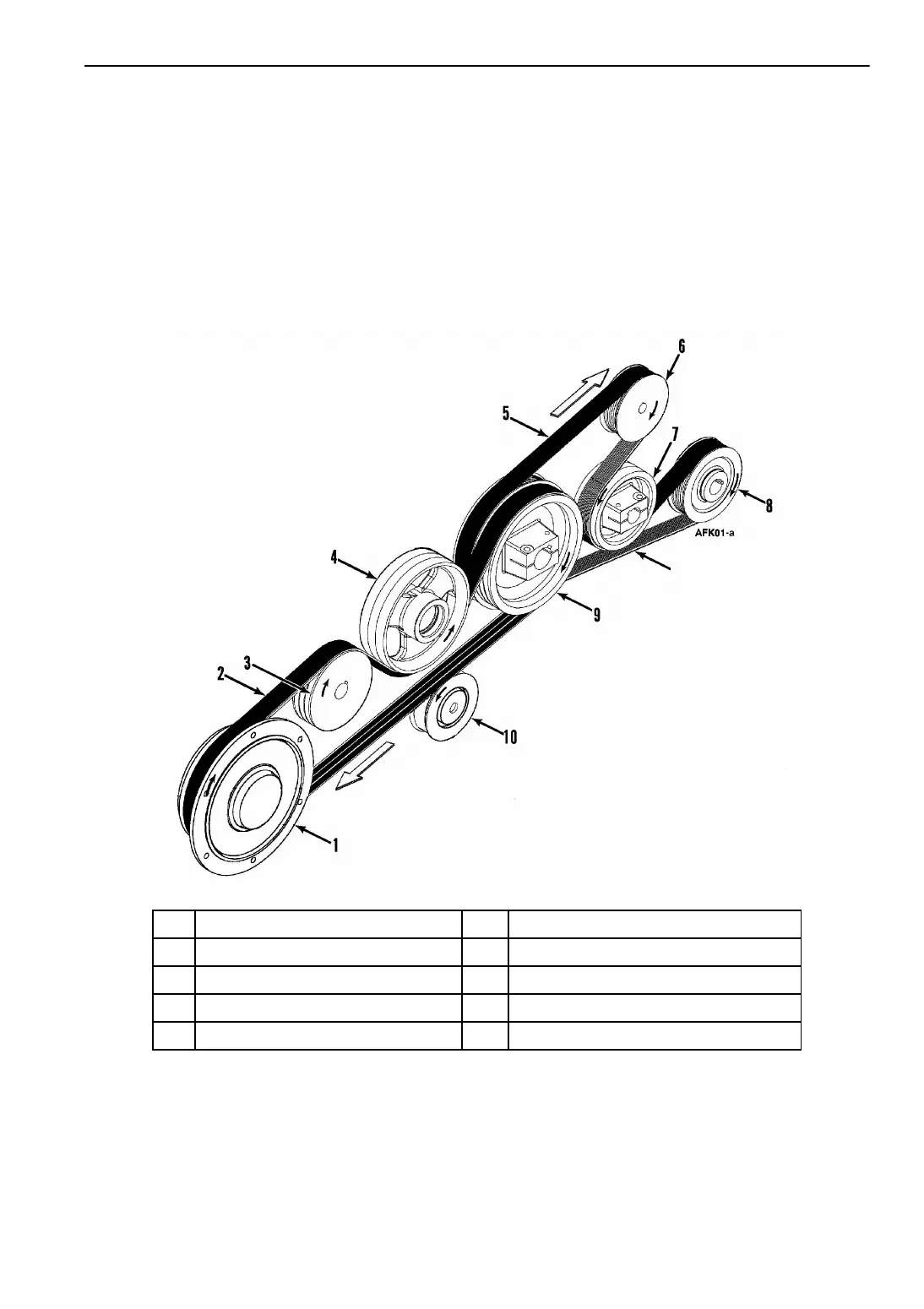

Belts

The unit uses only two belts to transfer power

from the engine and the electric motor to the

alternator, compressor, and evaporator fans.

Engine/Electric Motor Belt

The engine/electric motor belt is a 3V belt that

also drives the engine side evaporator fan. Use the

following procedure to adjust this belt.

1. Loosen the idler pulley mounting bolt.Loosen

the locknut on the idler pulley adjustment bolt.

This bolt is located directly above the idler

pulley on the idler pulley mounting bracket.

2. Turn the idler pulley adjustment bolt to obtain

the proper belt tension (field reset—55 to 60

on TK gauge, see Tool Catalog).

Tighten the locknut on the idler pulley adjustment

bolt and tighten the idler pulley mounting bolt.

NOTE: Pulley and

belt alignment is very

critical for poly-v

belts. Feel pulleys

with hand to see that

belt is fully seated in

pulley.

Backside idler

is crowned to

help pull belt to

center of idler.

1. Engine Clutch Pulley 6. Alternator Pulley

2. Locate Belt Tension Gauge Here 7 Evaporator Fan Pulley (Flat) Crowned

3. Evaporator Fan Pulley (Grooved) 8. Compressor Pulley

4. Idler (Backside) 9 Electric Motor

5. Locate Belt Tension Gauge Here 10. Belt Flop-Stop Idler

Figure 43: Front View Belt Arrangement

Loading...

Loading...