Refrigeration Maintenance

95

Refrigeration System Checks

NOTE: The Scroll compressor can not be

pumped down. Check the compressor efficiency

using the following procedure.

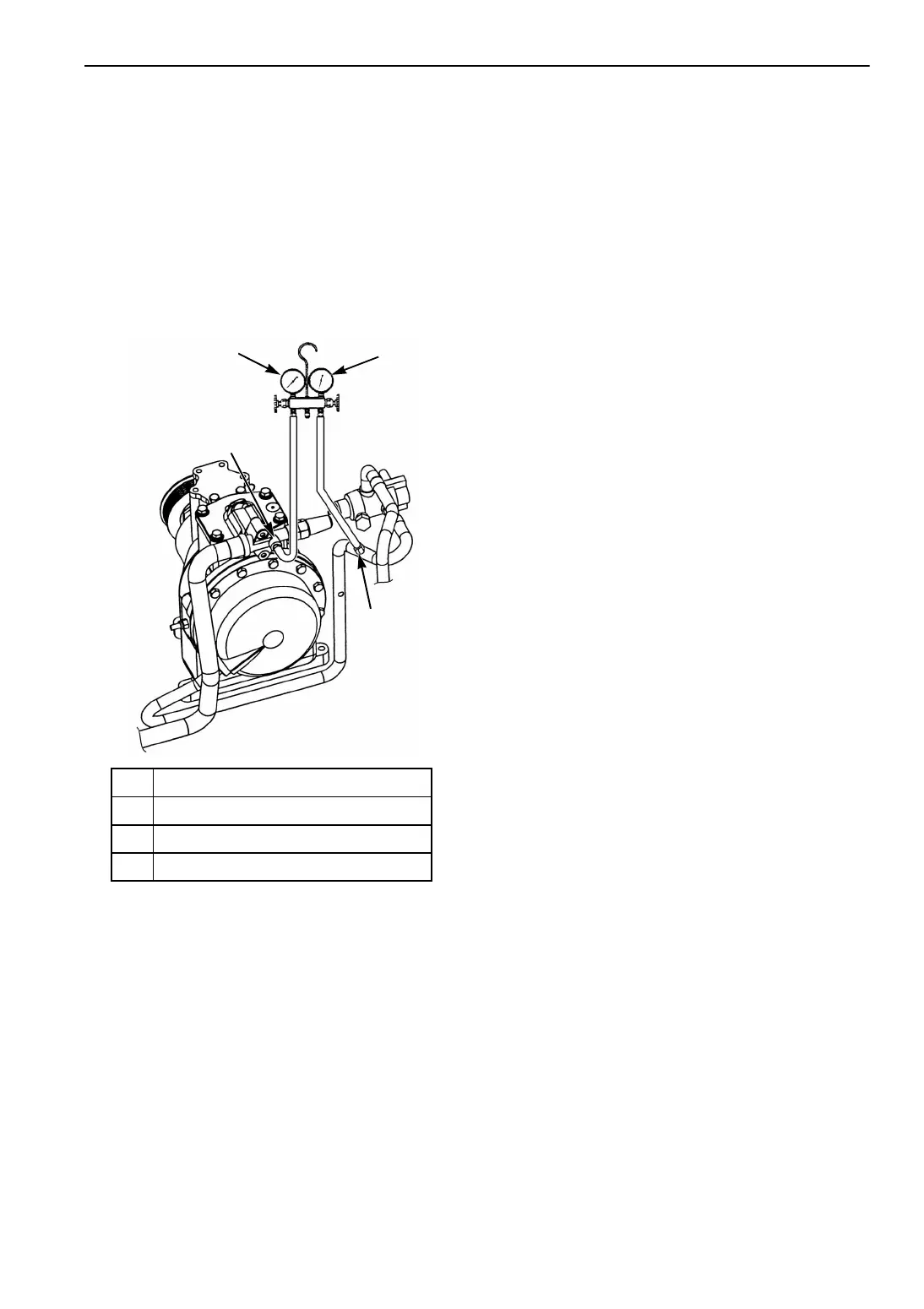

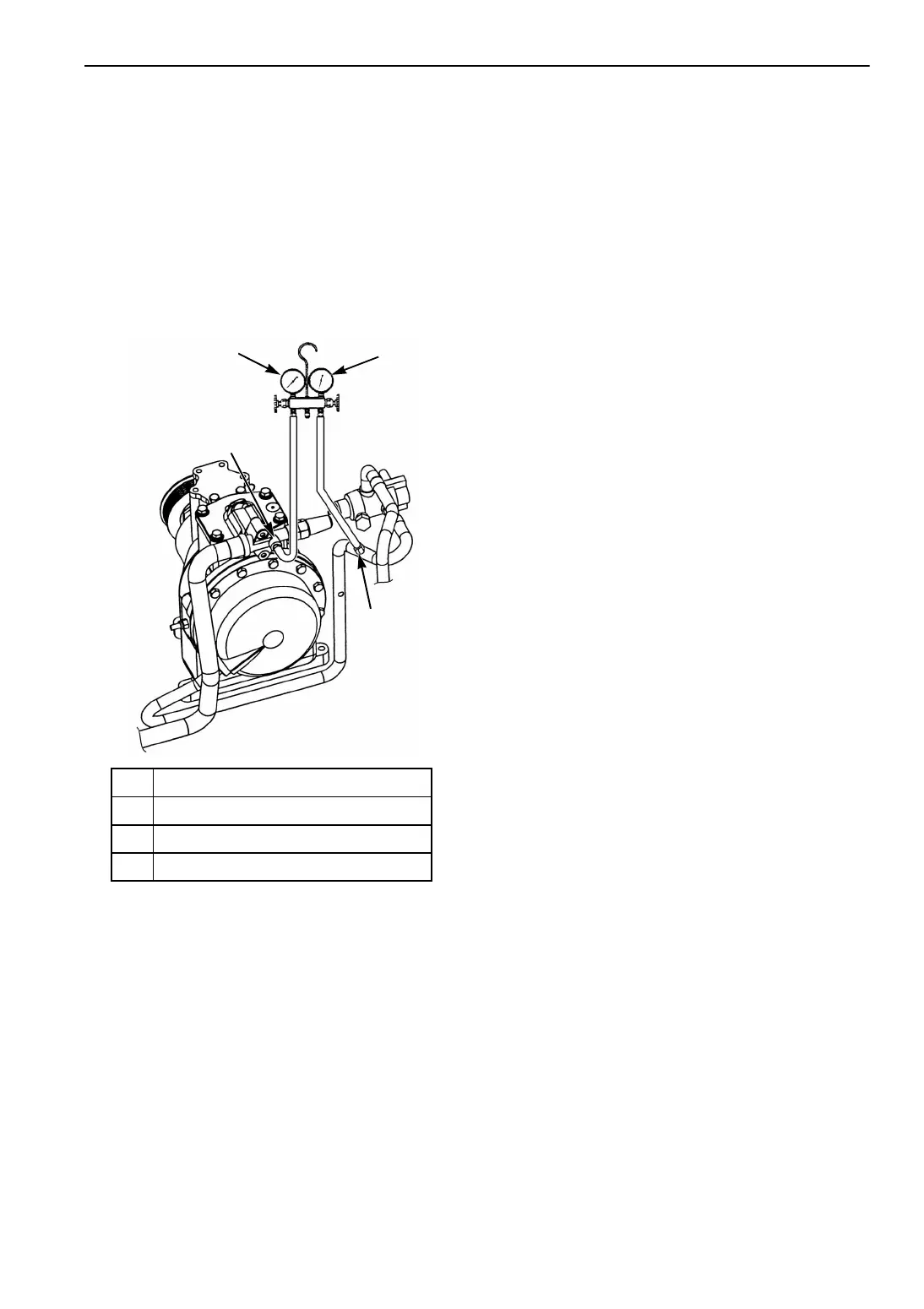

1. Install a gauge manifold set. Attach the

compound (low pressure) gauge to the service

port on the suction service valve. Attach the

high pressure gauge to the discharge service

port.

2. Run the unit in high speed cool until the

system pressures stabilize.

3. Note the head pressure on the high pressure

gauge.

4. Cover the condenser and check the head

pressure. The compressor should be able to

increase the head pressure at least 100 psig

(689 kPa). The compressor is probably faulty

if it cannot raise the head pressure 100 psig

(689 kPa).

Check the rest of the system by checking the

system pressures and the refrigerant flow in heat

and cool. The suction and discharge pressures

should be within the normal ranges for a standard

unit. Check the temperatures of the refrigeration

lines by hand to check the refrigerant flow.

Three-way Valve Condenser

Pressure Bypass Check Valve

The condenser pressure bypass check valve is

built into the three-way valve. This check valve

controls the bypass flow of refrigerant gas

between the condenser inlet line and compressor

discharge line.

The check valve is closed when the unit is running

on cool, or whenever the discharge pressure is

higher than the condenser pressure.

When the unit is running on defrost or heat, if the

condenser pressure is higher than the discharge

pressure, the check valve opens and the condenser

pressure is bled off until it drops to the level of the

discharge pressure. The purpose of the valve is to

improve heating/defrosting ability and three-way

valve response.

To check the operation of the valve:

1. Remove the condenser pressure bypass check

valve cap from the three-way valve.

2. Using a screwdriver, gently turn the check

valve stem in until the valve is front seated.

3. Install a service gauge manifold set on

compressor.

4. Close (front seat) the receiver tank outlet

valve.

1. Suction Service Valve

2. Compound Gauge

3. High Pressure Gauge (0 to 500 psig)

4. Discharge Service Port

Figure 50: Gauge Manifold Installation

AGA659

1

2

3

4

Loading...

Loading...