8

FluidConnectors

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

12

8.4 — Six-monthly maintenance

• Change the oil in the reduction unit using oil type GEARCO

85W-140 by NATIONAL CHEMSERACH or MOBIL

GLYCOLE 30 or KLUBER SINTHESO 460 EP or an equiva-

lent oil, proceed as follows:

• Remove the connecting plug

from the electric box and

un-screw the head moving

lever.

• Drain the old oil from the cap

at the side (1).

• Pour in new oil up to the

mark (1), through the lever

fixing hole, keeping the head

in a horizontal position (2).

• Reassemble all the parts.

• Check continuity of the equi-

potential protection circuit.

8.5 — Oils for lubricating coolant

Considering the vast range of products on the market, the

user can choose the one most suited to his own requirements,

using as reference the type SHELL LUTEM OIL ECO.

The minimum percentage of oil diluted in water is 8 - 10 %.

8.6 — Special maintenance

Special maintenance operations can be carried out by skilled

personnel, or contact Parker TFD or distribution personnel.

9

Material Classifiation and

Choice of Tool

Since the aim is to obtain excellent cutting quality, the various

parameters such as

hardness of the material, shape and thick-

ness, transverse cutting section

of the part to be cut,

choice of

the type of cutting blade, cutting speed

and

control of head

descent

, must be suitably combined.These specifications must

therefore be combined in a single operating condition accord-

ing to practical considerations and common sense, so as to

achieve optimum conditions.

We therefore advise you always to choose original spare

blades that guarantee superior quality and performance.

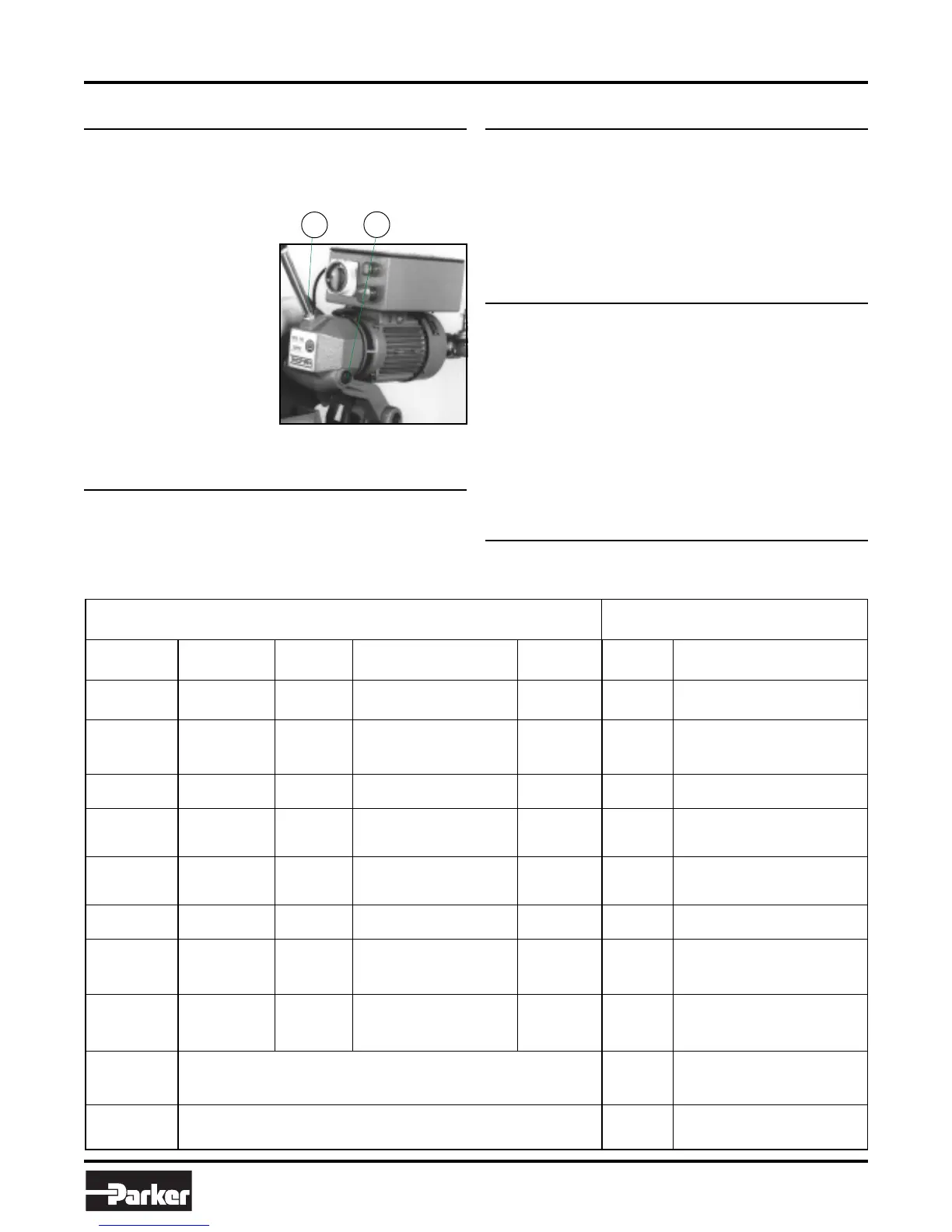

9.1 — Definition of materials

The following table lists the characteristics of the materials to

be cut.

TYPES OF STEEL CHARACTERISTICS

USE

I

UNI

D

DIN

F

AF NOR

GB

SB

USA

AISI-SAE

Hardness

BRINELL

HB

Hardness

ROCKWELL

HRB

R=N/mm2

Construction

steels

Fe360

Fe430

Fe510

St37

St44

St52

E24

E28

E36

----

43

50

----

----

----

116

148

180

67

80

88

360÷480

430÷560

510÷660

Carbon

steels

C20

C40

C50

C60

CK20

CK40

CK50

CK60

XC20

XC42H1

----

XC55

060 A 20

060 A 40

----

060 A 62

1020

1040

1050

1060

198

198

202

202

93

93

94

94

540÷690

700÷840

760÷900

830÷980

Spring steels

50CrV4

60SiCr8

50CrV4

60SiCr7

50CV4

----

735 A 50

----

6150

9262

207

224

95

98

1140÷1330

1220÷1400

Alloyed steels for

hardening and

tempering and for

nitriding

35CrMo4

39NiCrMo4

41CrAlMo7

34CrMo4

36CrNiMo4

41CrAlMo7

35CD4

39NCD4

40CADG12

708 A 37

----

905 M 39

4135

9840

----

220

228

232

98

99

100

780÷930

880÷1080

930÷1130

Alloyed

casehardening

steels

18NiCrMo7

20NiCrMo2

----

21NiCrMo2

20NCD7

20NCD2

En 325

805 H 20

4320

4315

232

224

100

98

760÷1030

690÷980

Steel for

bearings

100Cr6 100Cr6 100C6 534 A 99 52100 207 95 690÷980

Tool steel

52NiCrMoKU

C100KU

X210Cr13KU

58SiMo8KU

56NiCrMoV7

C100W1

X210Cr12

----

----

----

Z200C12

Y60SC7

----

BS 1

BD2 - BD3

----

----

S-1

D6 - D3

S5

244

212

252

244

102

96

103

102

800÷1030

710÷980

820÷1060

800÷1030

Stainless

steel

X12Cr13

X5CrNi1810

X8CrNi1910

X8CrNiMo1713

4001

4301

----

4401

----

Z5CN18.09

----

Z6CDN17.12

----

304 C 12

----

316 S 16

410

304

----

316

202

202

202

202

94

94

94

94

670÷885

590÷685

540÷685

490÷685

Copper alloys

Special brass

Bronze

Aluminium copper alloy G-CuAl11Fe4Ni4 UNI 5275

Special manganese/silicon brass G-CuZn36Si1Pb1 UNI5038

Manganese bronze SAE43 - SAE430

Phosphor bronze G-CuSn12 UNI 7013/2a

220

140

120

100

98

77

69

56,5

620÷685

375÷440

320÷410

265÷314

Cast iron

Gray pig iron G25

Spheroidal graphite cast iron GS600

Malleable cast iron W40-05

212

232

222

96

100

98

245

600

420

Loading...

Loading...