5

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

FluidConnectors

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

4.3 — Minimum requirements for the premises

housing the machine

• Main voltage and frequency complying with the machine mo-

tor characteristics.

• Environment temperature from -10°C to +50°C.

• Relative humidity not over 90%.

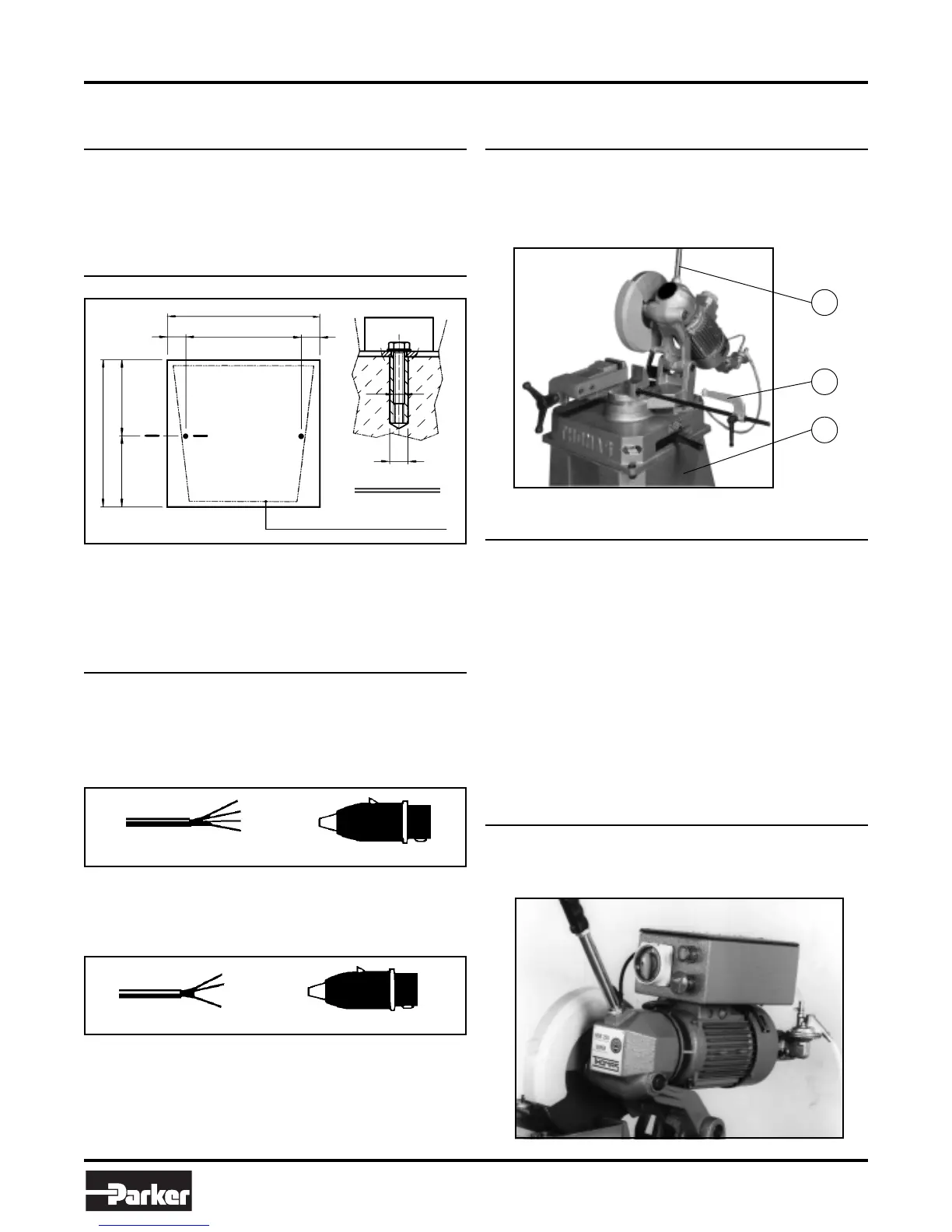

4.4 — Anchoring the machine

• Position the machine base on a firm cement floor, maintain-

ing, at the rear, a minimum distance of 800 mm from the

wall; anchor it to the ground as shown in the diagram, using

screws and expansion plugs or tie rods sunk in cement, en-

suring that it is sitting level.

4.5 — Instructions for electrical connection

• The machine may not be provided with an electric plug.

1 – WIRING DIAGRAM FOR 5-WIRE SYSTEM WITH NEU-

TRAL FOR THREE-PHASE MACHINE - SOCKET FOR A

16A PLUG

2 – WIRING DIAGRAM FOR THE SINGLE-PHASE SYSTEM

SOCKET FOR A 16A PLUG

PEDESTAL PROFILE

580

7070

440

270 290

560

AA

SEC. A - A

M8

12

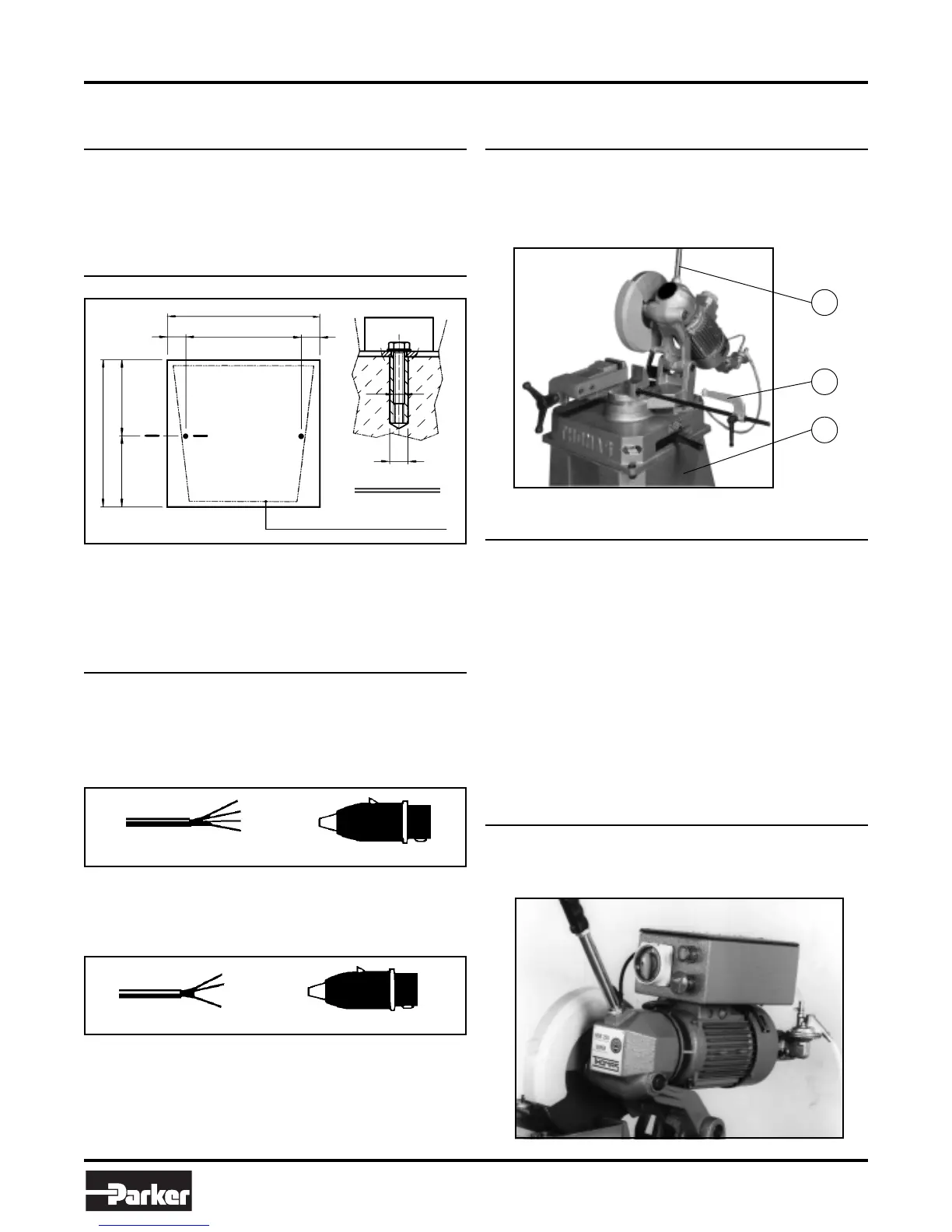

4.6 — Instructions for assembly of the loose

parts and accessories

Attach the components supplied as indicated in the photo:

• part. 1 Screw the lever onto the head

• part. 2 Attach the bar holding rod

• part. 3 Attach the pedestal firmly onto the base

4.7 — Deactivating the machine

If the sawing machine is not to be used for a long period, it is

advisable to proceed as follows:

1) Detach the plug from the electric supply panel

2) Release the head return spring

3) Empty the coolant tank

4) Carefully clean and grease the machine

5) If necessary, cover the machine.

5

Machine Functional Parts

5.1 — Operating head

• Machine part composed of the parts that transmit move-

ment (motor, reduction unit), the lubricating coolant pump

and the electrical components.

= L1

= L2

= PE

R = L1

S = L2

T = L3

PE = GND

N = NEUTRAL

2

1

3

Loading...

Loading...