6

FluidConnectors

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

5.2 — Vice

• System for gripping material during the cutting operation,

operated with handwheel.

Provided with an anti-burr device for holding the part that is

to be cut.

5.3 — Bed

• Support structure for the OPERATING HEAD (rotating arm

for gradual cutting, with respective blocking system), the

VICE, the BAR STOP, and the housing for the cutting cool-

ant TANK.

6

Description of the

Operating Cycle

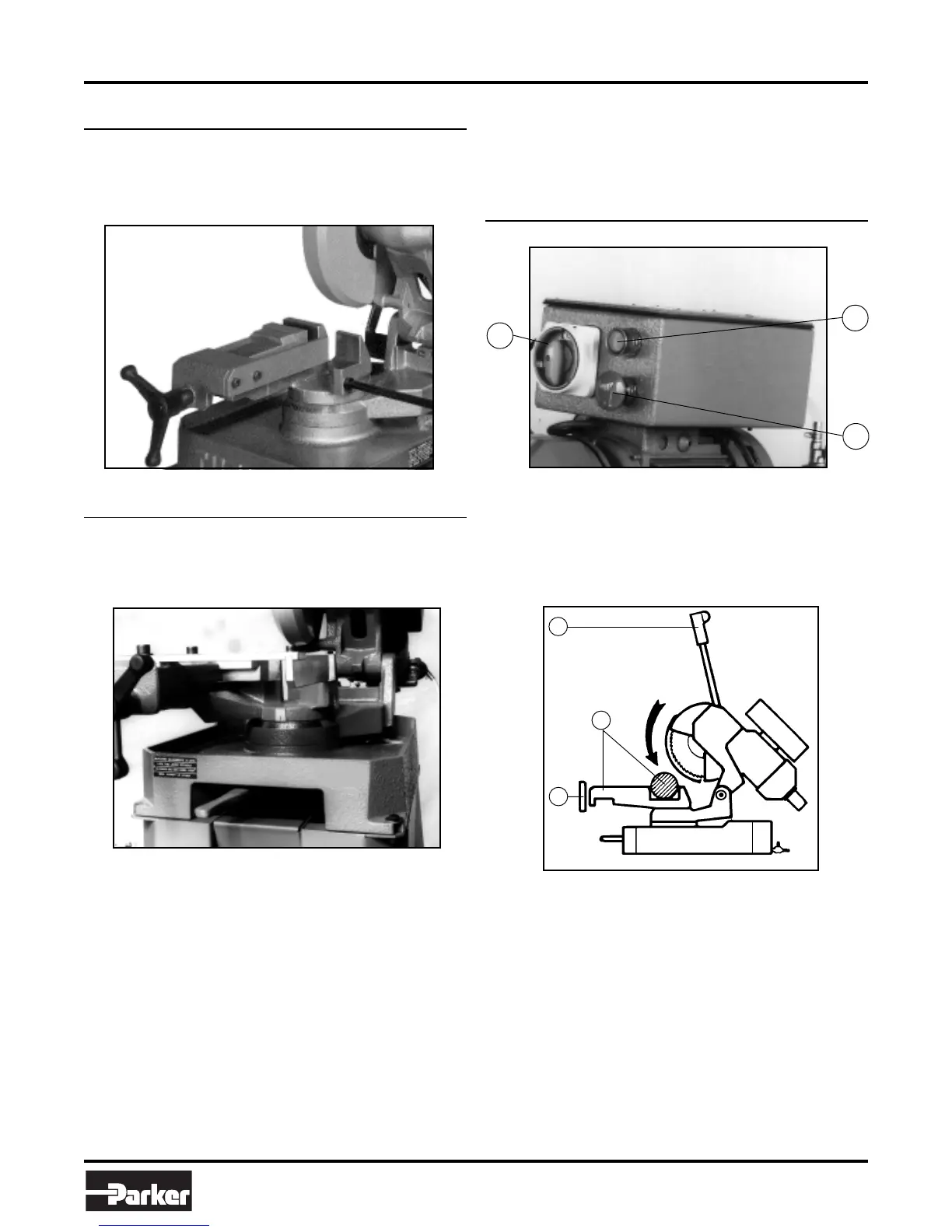

6.1 — Starting up and cutting cycle

• Ensure that the machine is not in emergency stop condition;

if it is, release the red mushroom button (1).

• Select the cutting speed on the switch (3):

position 1 = 40 rpm

position 2 = 80 rpm

• Press the start/reset button (2): green light will go on.

• Place material to be cut in the vice (4) and clamp the part

into place by handwheel (5).

• Grip the handle (6) of the HEAD control arm and press the

button, checking that the blade is turning in the direction

indicated (if not, invert the two phase leads) and that suffi-

cient coolant is flowing.

• When starting to cut with a new blade, in order to safe-

guard its life and efficiency, the first two or three cuts

must be made while exerting a slight pressure on the

part, so that the time taken to cut is about double the

normal time (see below in the chapter on “Material classi-

fication and choice of blades” in the section on

Breaking

in the blade

).

• Press the red emergency button (1) when there are condi-

tions of danger or malfunctions in general, so as to stop

machine operation immediately.

3

2

1

5

6

4

Loading...

Loading...