7

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

FluidConnectors

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

7

Regulating the Machine

7.1 — Saw head

• Does not require any adjustments.

7.2 — Vice

• Does not require any adjustments.

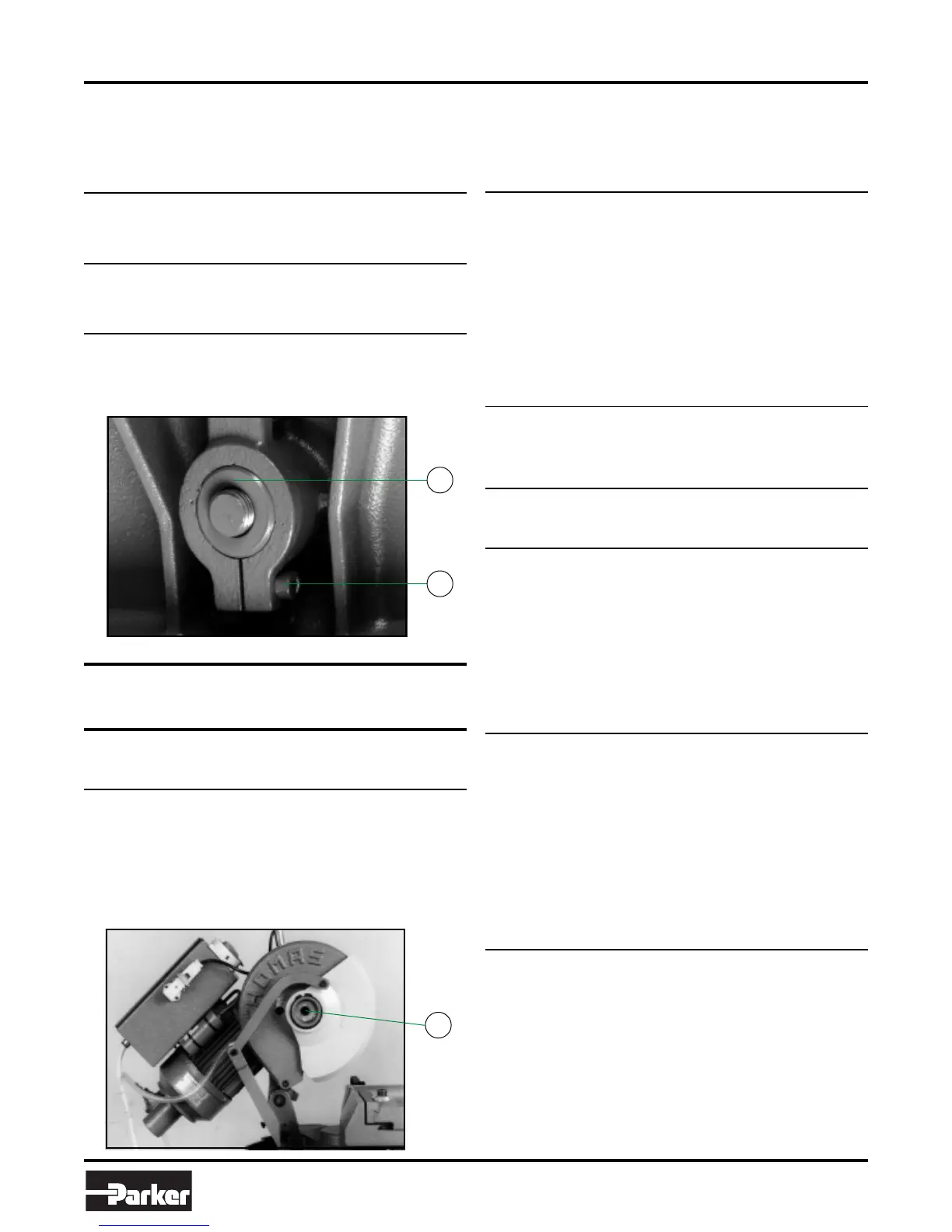

7.3 — Regulating arm blockage

• If there is blockage of the head arm in the desired position,

loosen the screw (1) on the lever, hold the bushing

(2) in position, turn the lever to the left and re-tighten the

screw.

Note: Before performing the following operations, the electric

power supply and the power cable must be completely

disconnected.

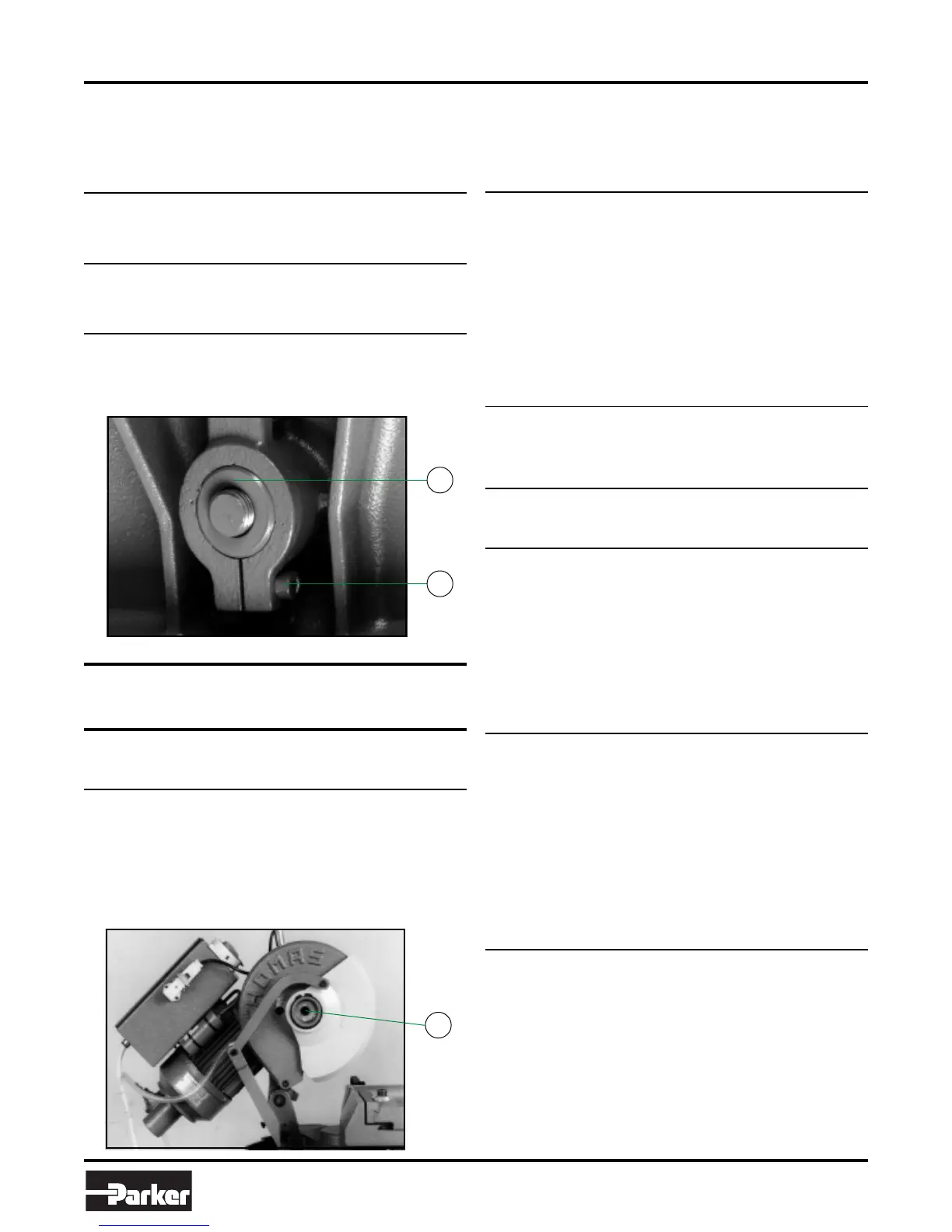

7.4 — Changing the blade

To change the blade:

• Release the guard and push it back.

• Place a piece of wood in the vice and lean the blade on it.

• Insert the special spanner provided and remove the screw

( 1 ), loosening it in a clockwise direction, it has a

left-handed

thread, then slip off the flange that holds the blade.

1

2

1

• Attach the new blade, check the direction of the teeth, then

replace the flange, the screw and the guard.

7.5 — Changing the lubricating coolant pump

• Remove the lubrication tubing.

• Remove the fastening screws and replace the small pump,

being careful to keep the driving stem centred on the drive

shaft bearing.

8

Routine and Special

Maintenance

The maintenance jobs are listed below, divided into

daily, weekly, monthly

and

six-monthly

intervals. If the

following operations are neglected, the result will be

premature wear of the machine and poor performance.

8.1 — Daily maintenance

• Clean the machine to remove accumulated shavings.

• Top off the level of lubricating coolant.

• Check the blade for wear.

• Lift the head into a high position to avoid yield stress on the

return spring.

• Check functionality of the guards and emergency stops.

8.2 — Weekly maintenance

• General cleaning of the machine to remove shavings, espe-

cially from the lubricant fluid tank.

• Clean the filter of the suction pump head and the suction

area.

• Clean and grease the screw and the sliding guide of the

vice.

• Clean the blade housing.

• Sharpen the blade.

8.3 — Monthly maintenance

• Check tightness of the screws on the motor, the pump, the

jaws and guards.

• Check that the guards are unbroken.

• Grease the head hinge pin.

Loading...

Loading...