10

FluidConnectors

Parker Hannifin Corporation

Tube Fittings Division

Columbus, OH

Bulletin 4390-974250

Cut 250 Saw Use and Maintenance Manual

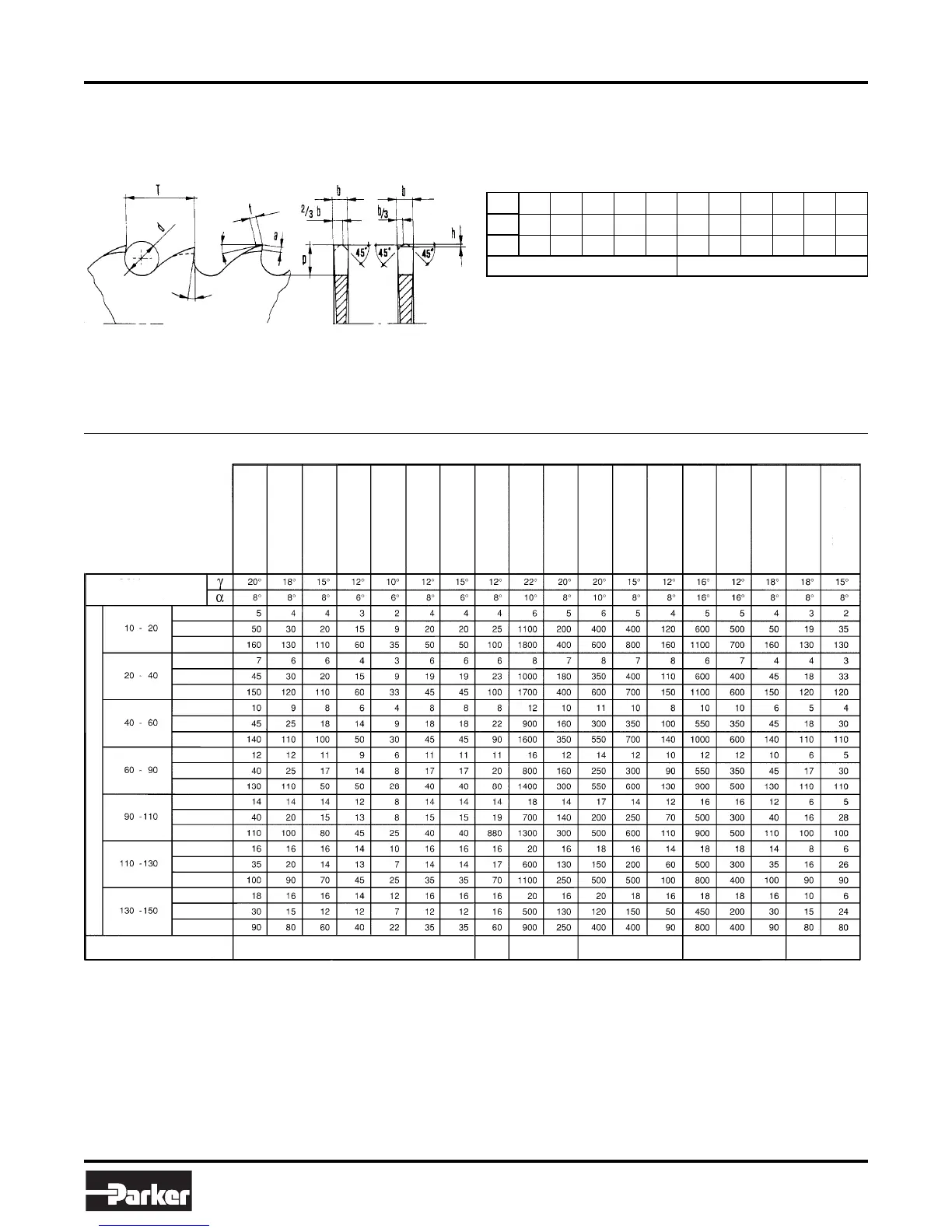

Sharpening circular saws

The rake varies especially according to the type of material to

be cut.

T

3 4 5 6 7 8 9 10 12 14 16

p

1,3 1,6 2,1 2,5 2,9 3,4 3,8 4,2 5,1 5,9 7,2

d 1,5 2 2,5 3 3,5 4 4,5 5 6 7 8

h = 0,2 mm h = 0,3 mm

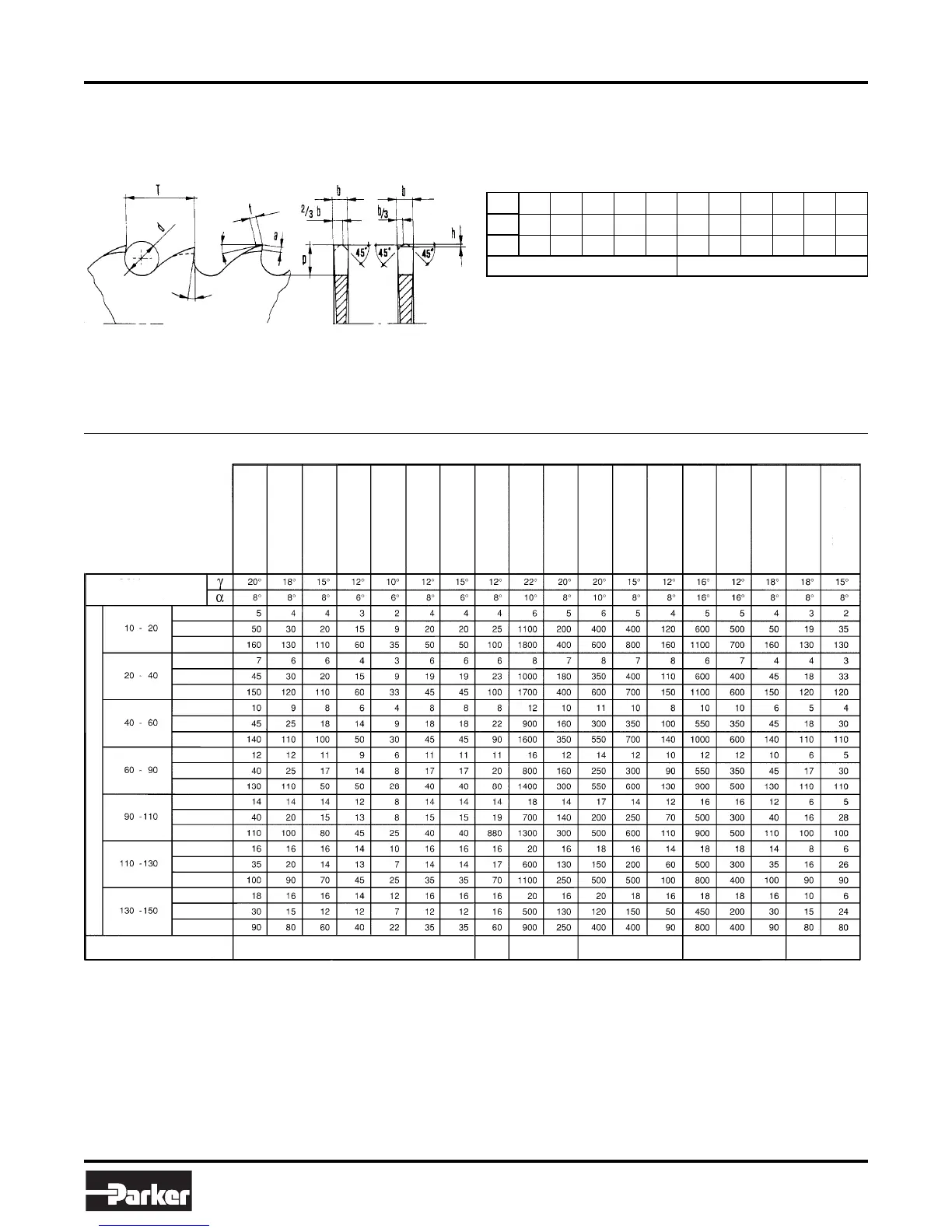

9.7.1 — Recommended cutting parameters

Mild steel

R = 350-500 N/mm

2

Aluminium and alloys

R = 300-300 N/mm

2

Tubes and beams

0,025. D

R = 300-600 N/mm

2

Brass

R = 200-400 N/mm

2

Titanium and alloys

R = 300-800 N/mm

2

Tubes and beams

0,05. D

R = 300-600 N/mm

2

Alloyed brass

R = 400-700 N/mm

2

Heat-treated steel

R = 950-1300 N/mm

2

Extra-hard steel

R = 950-1000 N/mm

2

Hard steel

R = 750-950 N/mm

2

Semi-hard steel

R = 500-700 N/mm

2

Grey cast iron

Aluminium and alloys

R = 200-400 N/mm

2

Copper

R = 200-350 N/mm

2

Phosphor bronze

R = 400-600 N/mm

2

Hard bronze

R = 600-900 N/mm

2

Austentic stainless

steel

R = 500-800 N/mm

2

Martensitic stainless

steel

R = 500-800 N/mm

2

Loading...

Loading...