164

164

NC2 0 - Manual - 01 - 2015

SETTING AND COMMISSIONING

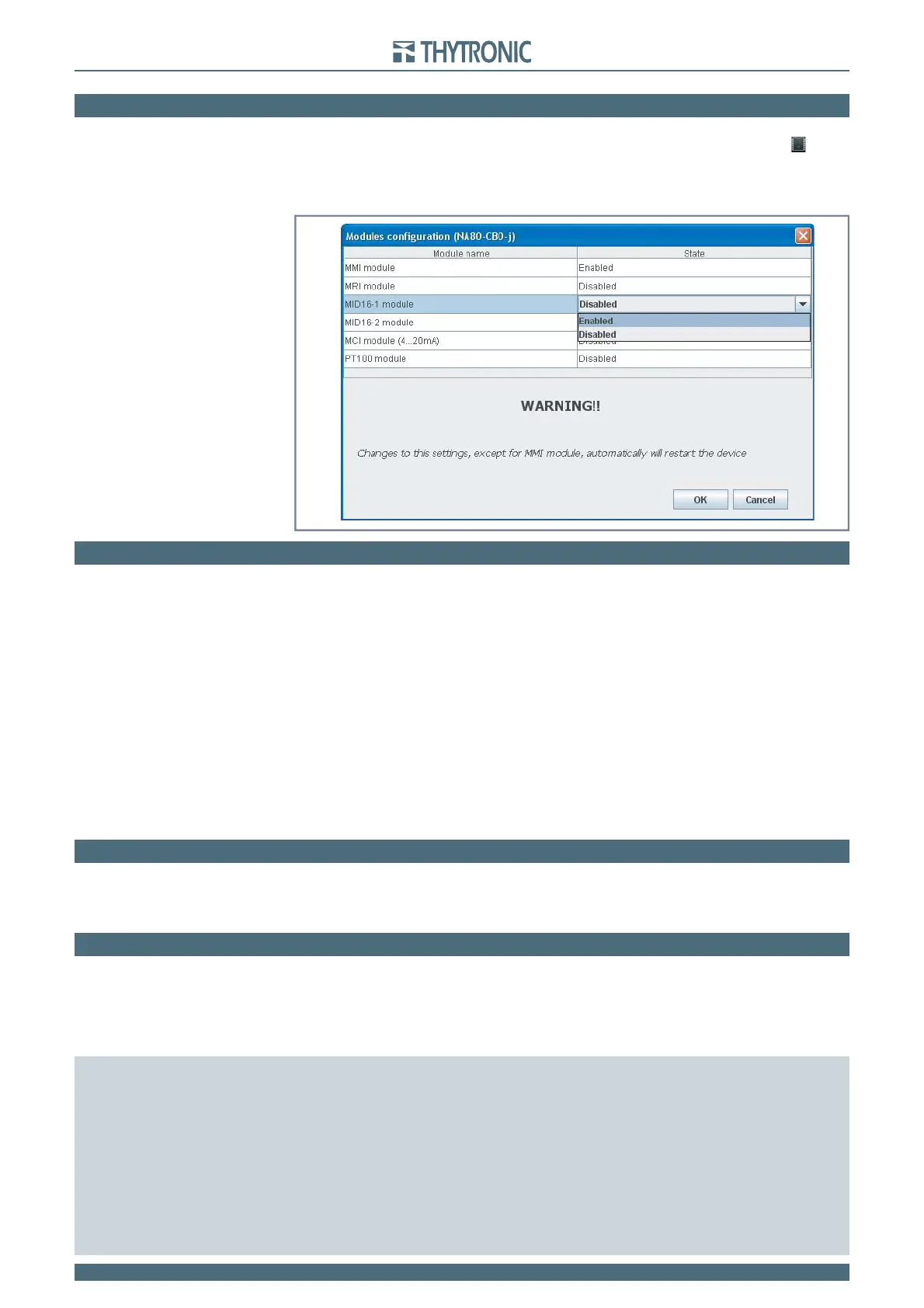

7.4 MODULES MANAGEMENT

After installation, the modules must be enabled (working with level 1 session level).

The Thybus modules may be set inside the Procedure menu (or by means a click on the

icon).

Following up any module confi guration an automatic reset is issued and the I/O devices are included

inside the device menu.

[1]

When two MID16 modules are enabled, the hardware address must be

set; the dip-switch layout is showed inside the INSTALLATION section

7.5 MAINTENANCE

The Pro-N relays do not require any particular maintenance; all circuits use high quality static com-

ponents, the subassembly products undergo dynamic checks on their functioning before the fi nal

assembling of the complete equipment. The dedicated circuits and the fi rmware for the self-test

function continuously check the relay operation; the continuously operating auto-zeroing function

dynamically corrects the measuring errors due to offset, heat dependent drifts, aging of components,

etc.

The microprocessor is equipped with a watch-dog circuit which restores the correct operation of

the fi rmware in case of fault.

The possibility of reading the value of the signals measured on the display (the NA60 relay used as an

ammeter) allows one to check both the system parameters and the operation of the protection relays

at any time. The NA60 relay can be preset as well to show the current values referred to the nominal

current of the current transformers, as directly in primary amperes (according to the preset value of

CT’s nominal primary current); the same is done for the input voltages.

If connected to the central control unit, all data available on the display can be checked and pro-

cessed thus performing a continuous check and maintenance.

7.6 REPAIR

No repair of possible faults by the client is foreseen; if following to any irregularity of operation, the

above tests confi rm the presence of a fault, it will be necessary to send the relay to the factory for

the repair and the consequent settings and checks.

7.7 PACKAGING

The Pro-N devices must be stored within the required temperature limits; the relative humidity should

not cause condensation or formation of frost.

It is recommended that the devices are stored in their packaging; in the case of long storage, espe-

cially in extreme climatic conditions, it is recommended that the device is supplied with power for

some hours before the commissioning, in order to bring the circuits to the rating conditions and to

stabilize the operation of the components.

Note 1 Binary inputs and output names (ThySetter):

Binary inputs for devices with two inputs onboard IN1, IN2 on board

IN3...IN10 with MRI module

IN11...IN26 with one MID16 module

IN27...IN42 with two MID16 modules

Binary inputs for devices with fi ve inputs onboard IN1...IN5 on board

IN6...IN13 with MRI module

IN14...IN29 with one MID16 module

IN30...IN45 with two MID16 modules

Output relays K1...K6 on board

K7...K10 with MRI module

LEDs: ON, START, TRIP, L1...L5 on board

L6...L10 with MRI module

Loading...

Loading...