10

TigerStop Installation

For non-pneumatic tools, the 24V of the Air Solenoid are capable of driving an electronic relay to the same

eect. Some wiring required.

ai r So le noi d fun cTion

The air solenoid cuts the tool’s air supply when TigerStop is in motion.

liM iT SwiTc H in STall aTi on

• Mount the Limit Switch to the tool.

* A suitable mounting location causes the Limit Switch to close when

the tool is at rest and to open when the tool is cycling.

* Make sure the SIK cable can reach the Amplifier.

* Drill and tap, as required.

Lockout/Tagout the tool and TigerStop before installation.

• TigerStop in Motion: Closes the Air Solenoid and the tool cannot move.

• TigerStop at Rest: Opens the Air Solenoid and the tool is free to move.

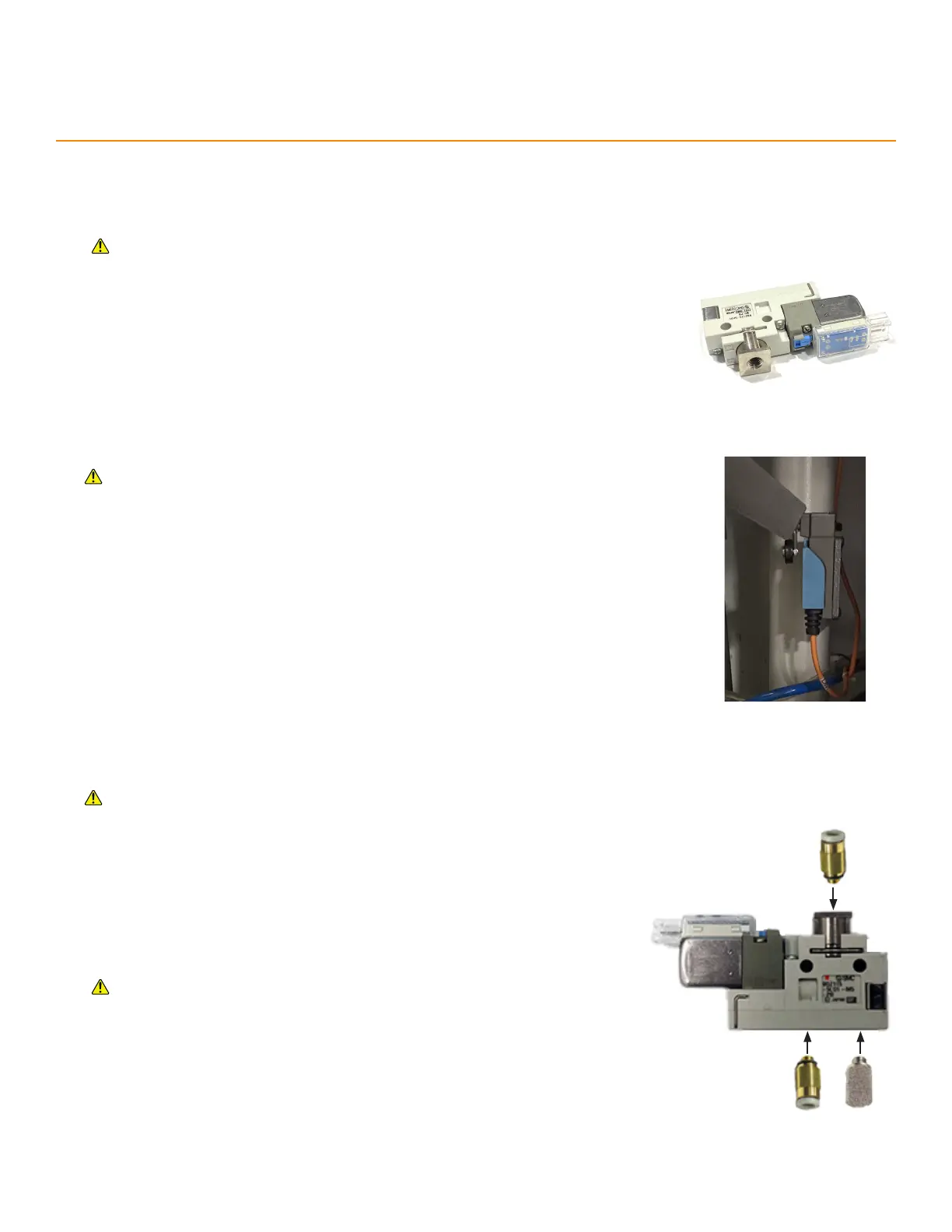

ai r So le noi d in STall aTio n

1. Determine which of the tool’s air lines is the “IN” line.

2. Disconnect the “IN” line, and measure it’s outside diameter. If the

diameter is neither 6mm nor 4mm, supply the appropriate sized M5

fittings for the air line.

3. Attach the appropriate M5 fittings and Exhaust Muer to the Air

Solenoid.

Before proceeding to the next step, ensure the SIK cable can reach the

Amplifier and the Red & Black wires’ plug can reach the desired Air

Solenoid location.

4. Cut the tool’s “IN” air line and attach the supply side to the Air

Solenoid’s intake, next to the Exhaust Muer. Attach the tool side to the

outflow on the opposite side of the Air Solenoid.

5. Connect the Red & Black wires’ plug on the SIK cable to the Air

Solenoid.

Lockout/Tagout the tool, TigerStop, and air supply before installation.

“IN” Air

“OUT” Air

Muffler

Loading...

Loading...