35

Maintenance Schedule

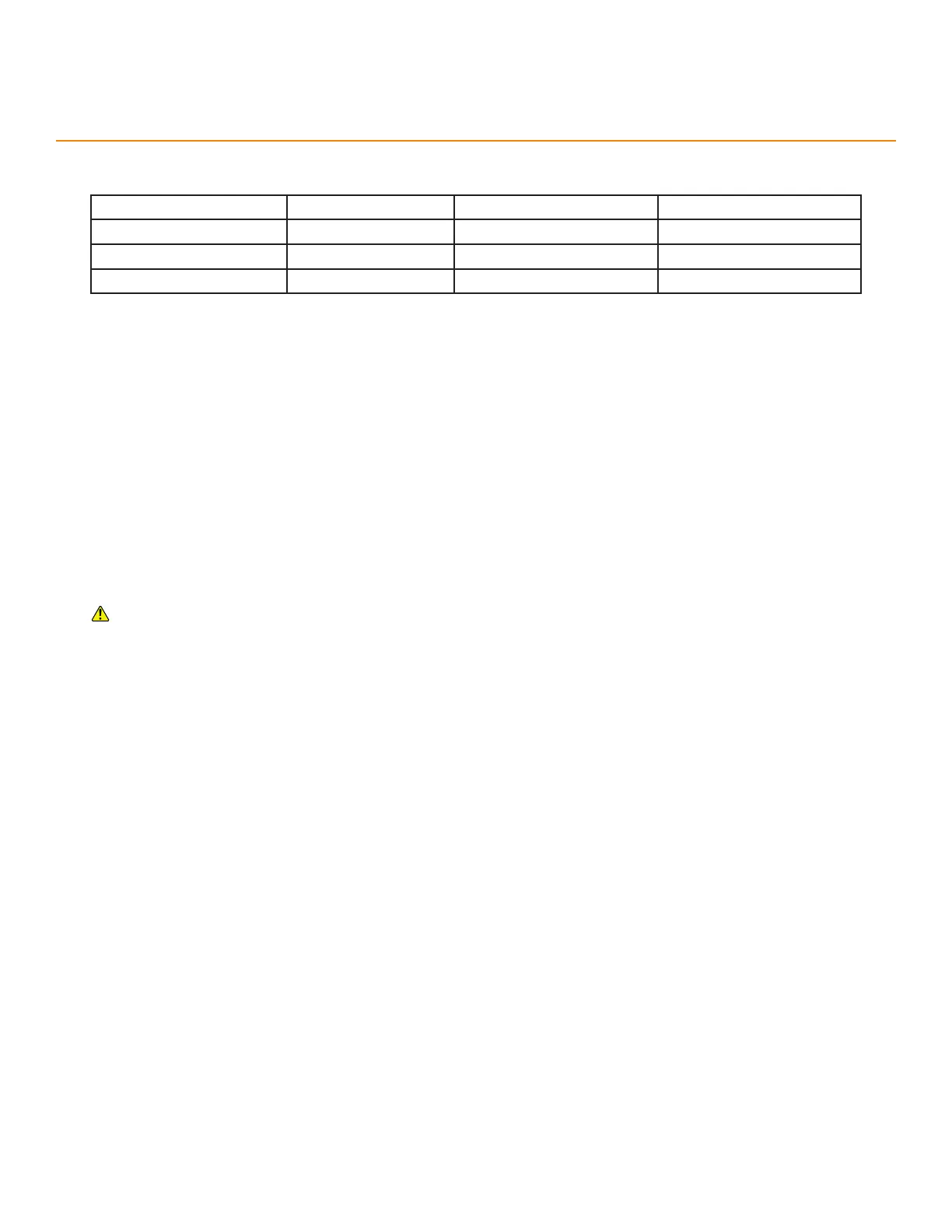

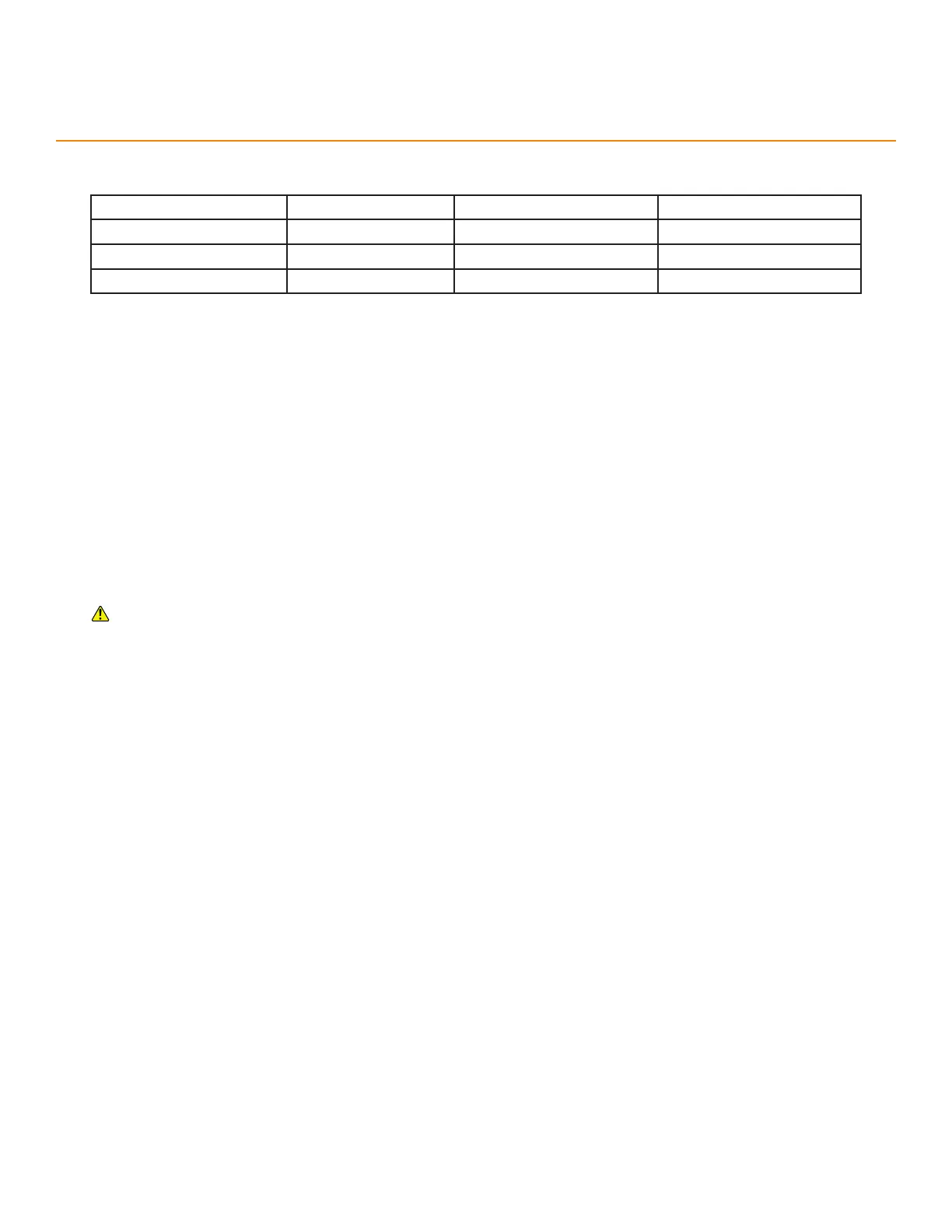

reco rd iMp o rTanT SeT Ti ngS

Setting Value Setting Value

Serial # Scale

Min Limit Kerf

Max Limit Lash

dai lY

• Clean all dirt and debris from drive areas.

• Check all cables for damage.

• Check calibration, if necessary.

Mo nTH lY

• Blow dust o machine exteriors, especially cable connections.

• Blow out dust from inside the trim strips on the main beam.

When blowing out dust, always blow away from the motor end of the beam. Exercise caution when using

forced air nozzles.

quarTe rlY (everY 3 Mo nTH S)

• Check nylon set screws in the flip away stop. Make sure they are properly adjusted and not missing. If the

flip away stop is dragging or scraping on the machine or feed table, adjust the set screws to eliminate this.

• Run a motor drive test and record the data in the maintenance log. If drive numbers are above 12000,

contact TigerStop

®

Customer Service.

Loading...

Loading...