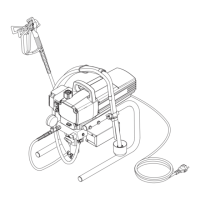

14 Performance Series 450e

Servicing Repairs at the unit

10. Servicing

10.1 General servicing

Servicing of the unit should be carried out once annually by the

TITAN service.

1. Check high-pressure hoses, device connecting line and

plug for damage.

2. Checktheinletvalve,outletvalveandlterforwear.

10.2 High-pressure hose

Inspect the high-pressure hose visually for any notches or

bulges,inparticularatthetransitioninthettings.Itmustbe

possible to turn the union nuts freely.

11. Repairs at the unit

Switch the unit OFF.

Before all repair work: Unplug the power plug

from the outlet.

11.1 Relief valve

1. Useadriftpunchof2mmtoremovethegroovedpin(Fig.

8,Item1)fromthereliefvalvehandle(2).

2. Removethereliefvalvehandle(2)andcambase(3).

3. Usingawrench,removethevalvehousing(4)fromthe

pumpmanifold(6).

4. Ensurethattheseal(5)isseatedcorrectly,thenscrewthe

newvalvehousing(4)completelyintothepumpmanifold

(6).Tightensecurelywithawrench.

5. Alignthecambase(3)withtheholeinthepumpmanifold

(6).Lubricatethecambasewithgreaseandslideonthe

cam base.

6. Bringtheholeinthevalveshaft(7)andinthereliefvalve

handle(2)intoalignment.

7. Insertthegroovedpin(1)tosecurethereliefvalvehandle

in position.

11.2 Inlet and outlet valve

1. Remove the four screws in the front cover and then

remove the front cover.

2. SwitchtheunitONandthenOFFsothatthepistonrodis

positioned in the lower stroke position.

Danger of crushing - do not reach with the

ngers or tool between the moving parts.

3. Unplugthepowerplugfromtheoutlet.

4. Remove the retaining clip from the connecting bend at the

suction hose and pull off the suction hose.

5. Screw off the return hose.

6. Swiveltheunit90°totherearinordertoworkmoreeasily

on the material feed pump.

7. Unscrewtheinletvalvehousing(Fig.9,Item1)fromthe

pump manifold.

8. Removethelowerseal(2),lowerballguide(3),inletvalve

ball(4),inletvalveseat(5)andO-ring(6).

9. Clean all the parts with the corresponding cleaning agent.

Checktheinletvalvehousing(1),inletvalveseat(5)

andinletvalveball(4)forwearandreplacethepartsif

necessary.Iftheworninletvalveseat(5)isunusedon

one side, install it the other way round.

10. Unscrewoutletvalvehousing(Fig.10,Item7)fromthe

piston(8)withadjustingwrench.

11. Removetheupperballguide(10),crushwasher(9),outlet

valveball(11),andoutletvalveseat(12).

12. Clean all the parts with the corresponding cleaning agent.

Checkoutletvalvehousing(7),outletvalveseat(12),

outletvalveball(11)andupperballguide(10)forwear

and replace parts if necessary. If the worn outlet valve

seat(12)isunusedononeside,installittheotherway

round.

13. Carry out installation in the reverse order. Lubricate O-ring

(Fig.9,Item6)withmachinegreaseandensureproper

seatingintheinletvalvehousing(Fig.9,Item1).

Loading...

Loading...