TM 9-1829A, April 1944 65/100 2021-07-07

Pointer deflection (in

degrees) at 60 mph (1000

rpm)

1

Pointer deflection (in

degrees) at 60 mph (1000

rpm)

1

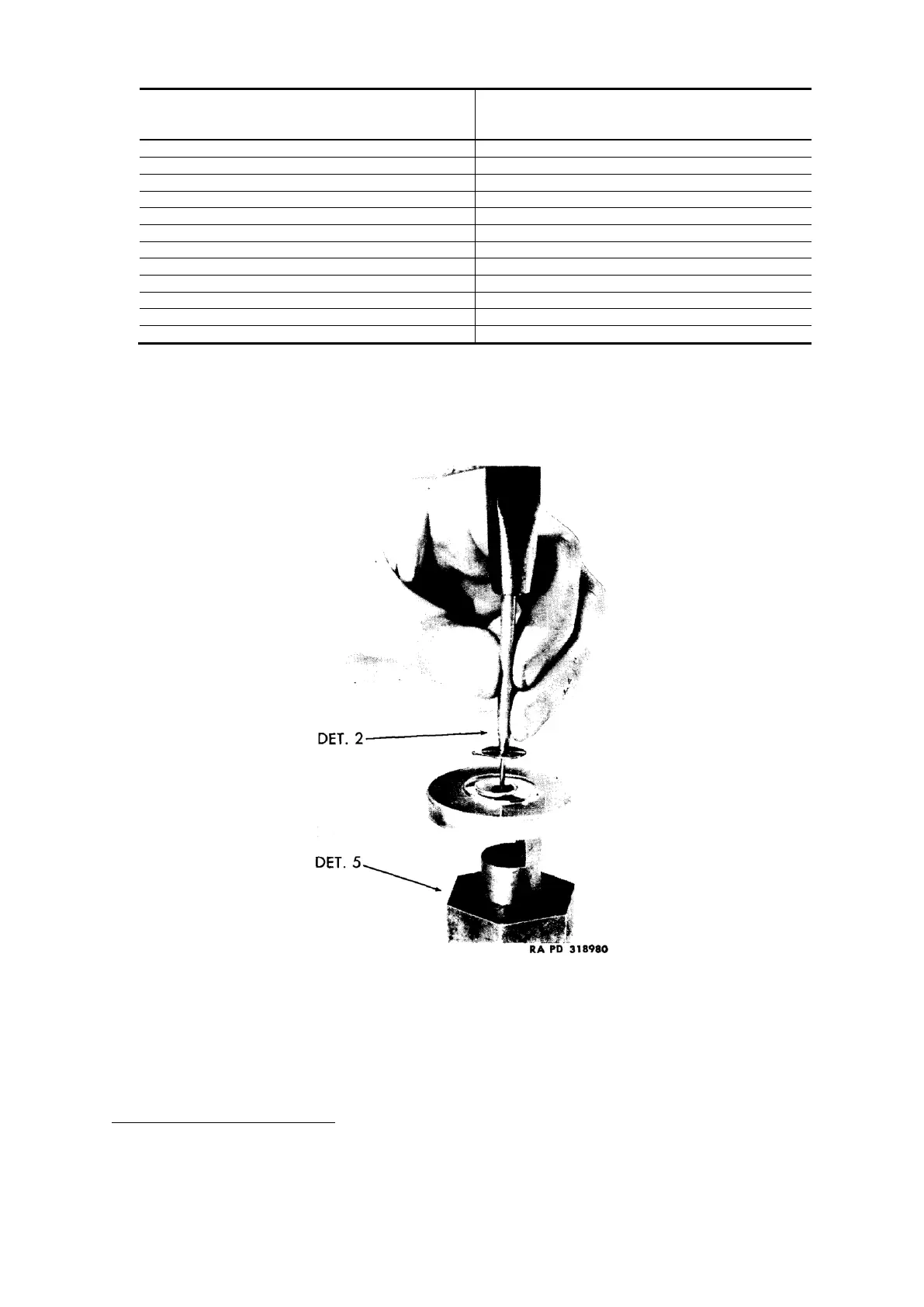

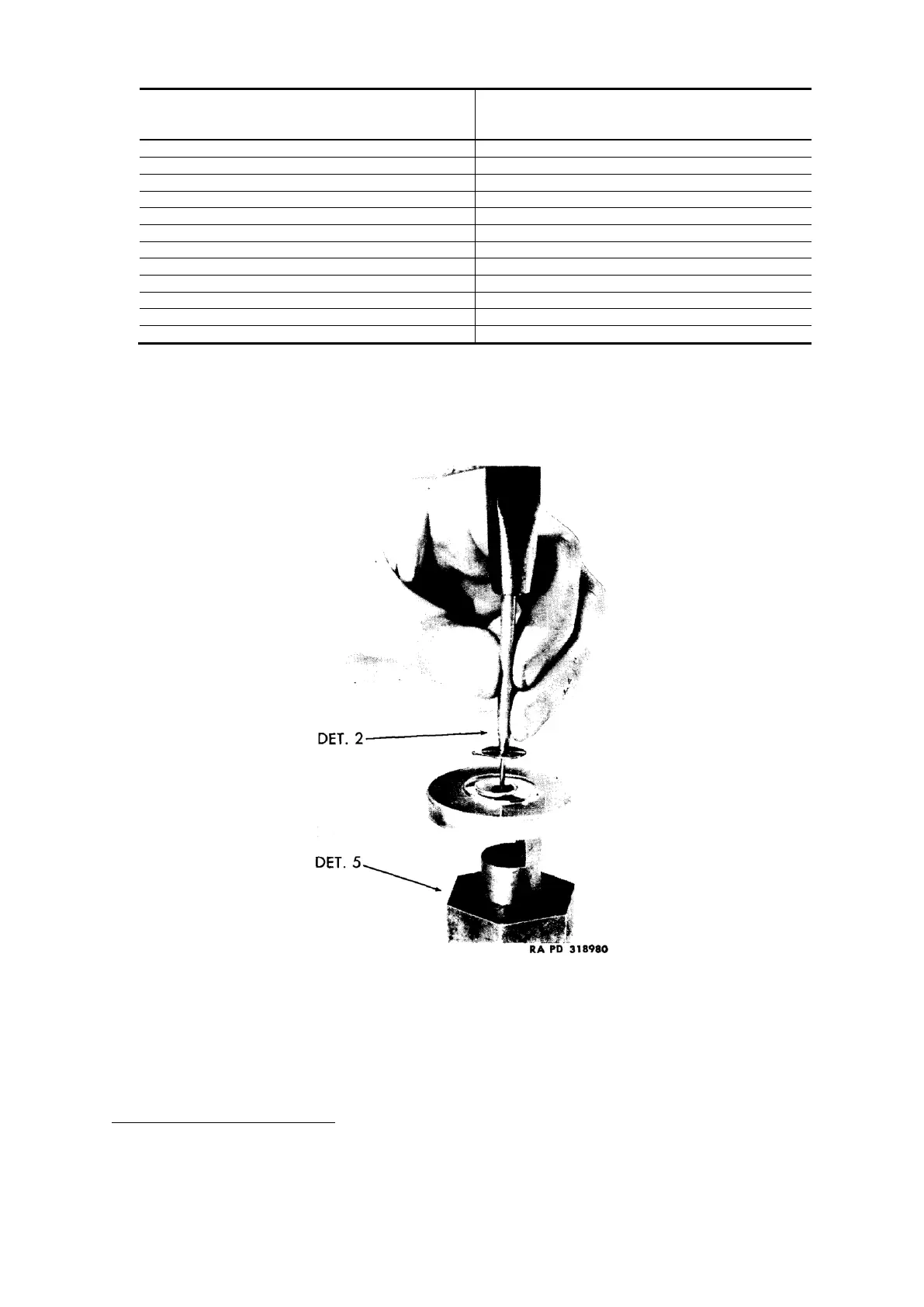

e. Assemble speed unit: Place speed cup on anvil of hair spring assembly fixture (T-29 Det 5). Place hair spring

over end of staff with loose end pointing counterclockwise, if instrument has clockwise face dial. If instrument

has counterclockwise face dial, then the loose end of the hair spring should point in a clockwise direction.

Using female punch (T-29 Det. 2), carefully drive hair spring on staff leaving about

1

/

8

inch clearance between

hair spring collet and speed cup (fig. 95).

Figure 95: Replacing hair spring, using assembly kit (T-29)

As the position of the numerals on the dial vary a great deal on different model speedometers, it is necessary to

take this fact into consideration when selecting the proper hair spring to go with each magnet. Therefore, the above

list is provided showing the angle (measured in degrees) that the pointer travels between zero dial reading and 60

miles per hour dial reading. If the model number of the speedometer being repaired does not appear in above list,

the angle of pointer travel from zero to 60 miles per hour on the dial may be easily determined with a protractor.

Loading...

Loading...