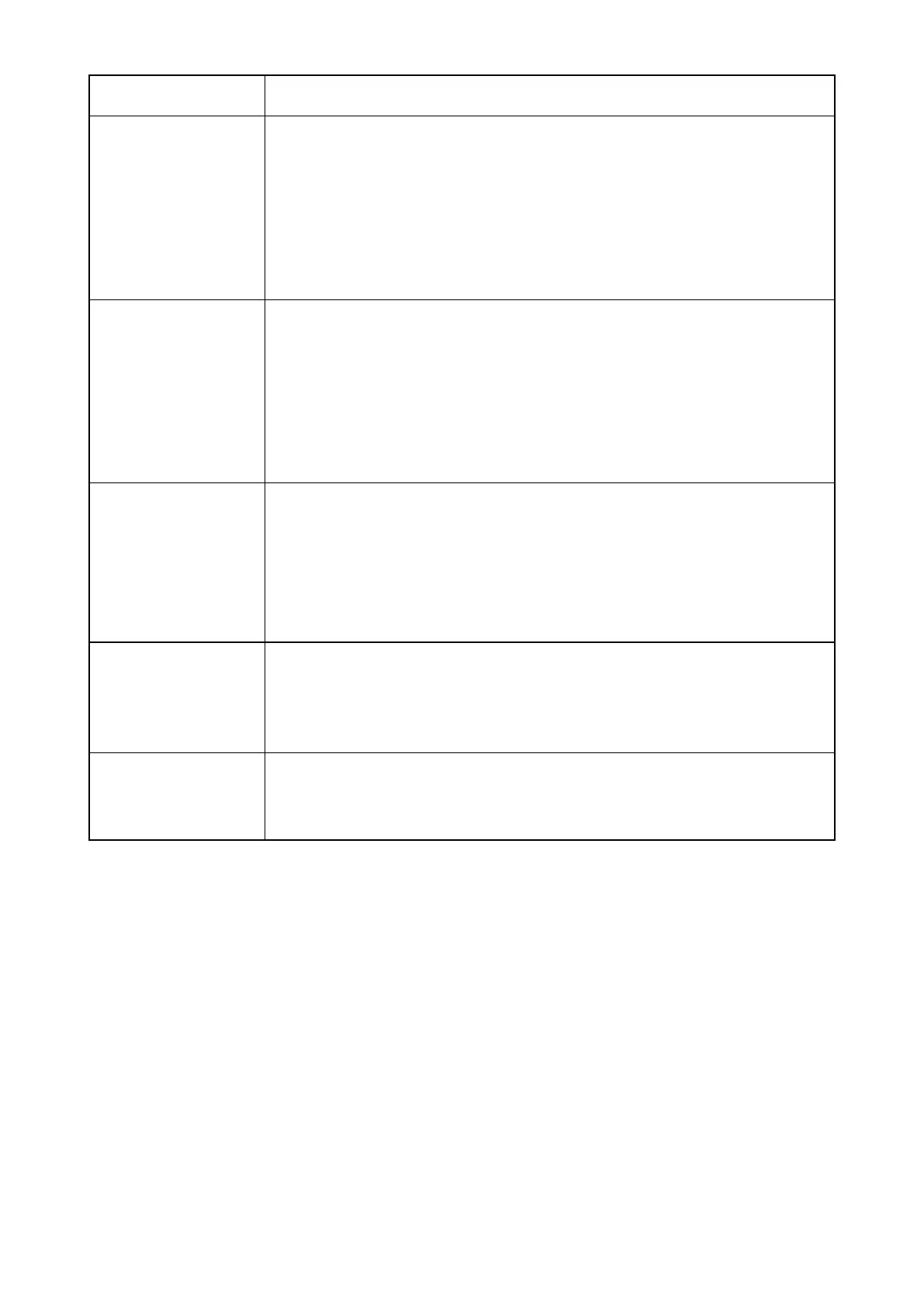

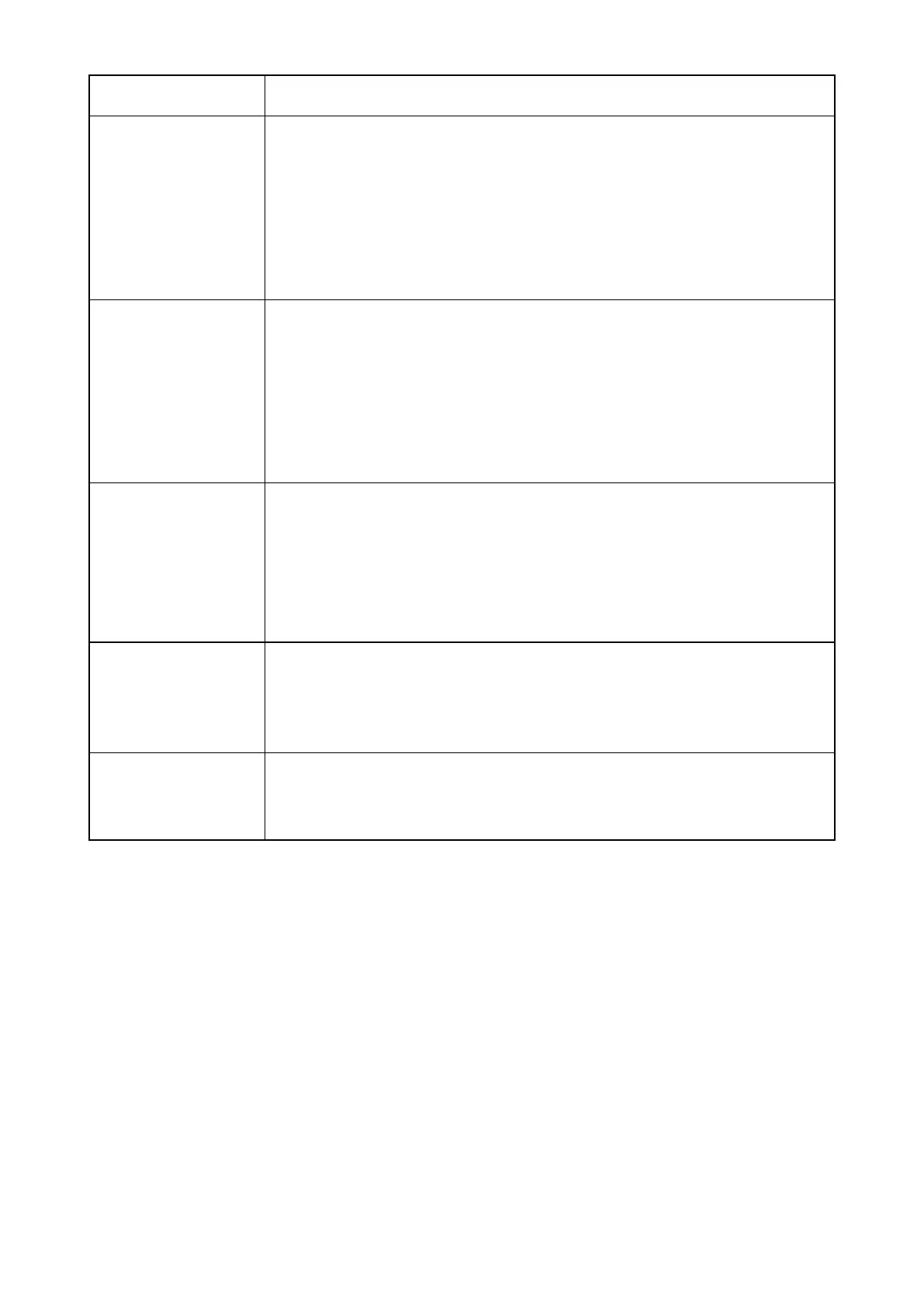

Maintenance

Every six months check the following items for proper operation of the unit.

* Lubricate shafts and sprockets.

* Keep operator clean at all times.

* Check and tighten anchors bolts.

* Check for loose or corroded wire

* Ensure the operator is well earthed, and correctly terminated.

* Always check the Stop/Reverse in case of obstruction function when performing any maintenance. If

this function can’t be made operable, remove this operator from service until the cause of the

malfunction is identified and corrected.

4. Check the control board. Replace the control board as necessary.

The gate starts but it

is immediately stop or

reverse

1. Check the wire connection of hall sensor board with the main control

board.

2. The opening force or closing force is adjusted too small. Turn the

Potentiometer A to increase the force.

3. Disconnect the gate from the gate opener and check that the gate slides

freely without any binding.

4. Check the control board. Replace the control board as necessary.

The gate opens, but

stops and will not

return.

1. Check the installing position of the magnets. The opener would not run if

both of the limit switches are activated by one magnet.

2. Check the limit switch. Remove the wire connection of the limit switch

which is connected to the 8#, 9#, and 10# terminals of the control board and

then use a jumper wire to short the 3 terminals together to try it again.

Replace the limit switch if the motor could run in both directions.

3. Check the control board. Replace the control board as necessary.

The gate can open,

but fails to close.

1. Photocell is obstructed. Remove obstruction.

2. Check the limit switch. Remove the wire connection of the limit switch

which is connected to the 8#, 9#, and 10# terminals of the control board and

then use a jumper wire to short the 3 terminals together to try it again.

Replace the limit switch if the motor could run in both directions.

3. Check the control board. Replace the control board if necessary.

The gate will open

automatically instead

of close after the auto

close time

Ensure the DIP 4# has been set correctly according to the installation for

“Left Open” or “Right Open”

The motor runs but

the gate doesn’t

move.

Ensure the clutch for emergency release is adjusted properly and is not

slipping.

Loading...

Loading...