EN-21T75 DES

Functional force monitoring check

Upon completion of the force measurement process, carry out a

functional check of the force monitoring function. Install the test

weight on the door again for this purpose. The drive must switch

off!

NOTICE

Force monitoring has not tripped during the

functional check

If the force monitoring function has not tripped,

the settings in menu item48 must be checked.

The force measurement process must be re-

peated.

Duty cycle (menu item49)

The duty cycle set prevents the drive motor from being over-

heated and avoids damage.

NOTICE

Motor5.24 with a plastic gearbox

When motor5.24 with a plastic gearbox is used,

the duty cycle must be set to the value1 (3~) or

2 (WS,1~).

Menu6 Radio settings

Programming the hand-held radio transmitter

Please observe that every hand-held transmitter must be pro-

grammed individually.

You are provided with the possibility of programming 20KeeLoq

radio codes

The following encryption types can be programmed: KeeLoq,

12 Bit Multibit. The first code programmed determines the encryp-

tion type.

Start pulse (menu item60)

1. Select "Program hand-held transmitter start button" in menu

item60.

2. Actuate the button of the hand-held transmitter for opening

the door.

ð When the code has been programmed, the dot display

on the LED display blinks 5times.

3. Go to Exit to complete the setting process.

Light function (menu item62)

Select menu item62 and actuate the light function button of the

hand-held transmitter. When the code has been programmed, the

dot display on the display blinks 5times.

Deleting radio codes (menu item63)

To delete all codes programmed, proceed as follows:

1. Select menu item63.

2. Press and hold the button for 5seconds.

When all codes have been deleted, the dot display on

the display blinks 5times.

Test run

When programming has been completed, carry out a test run by

executing all operating functions. When all operating functions

have been executed correctly, the connected door system is

ready for operation.

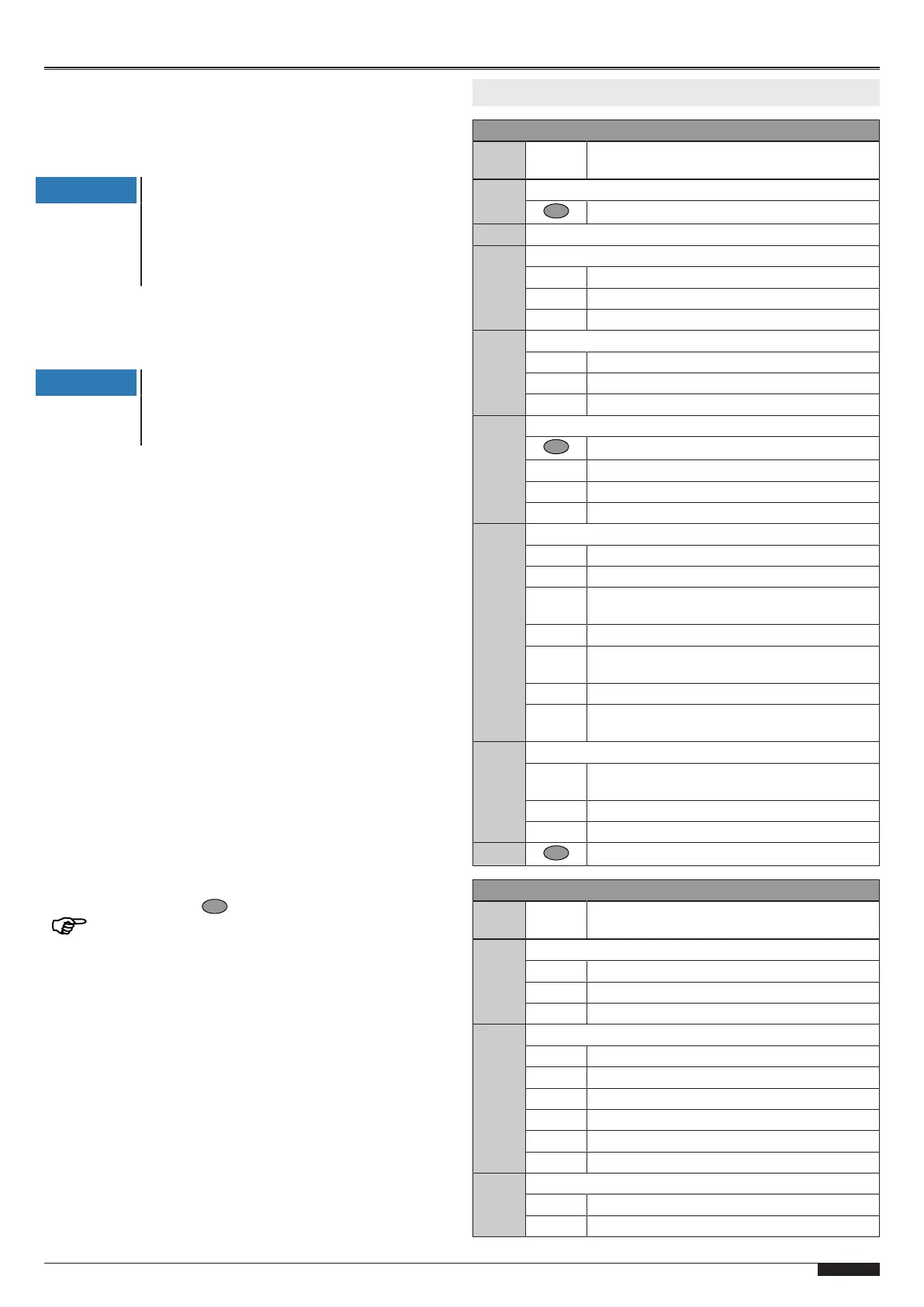

6 Program overview

Menu3 Basic settings

Menu

item

Entry Selection

30 Door setting of upper end position

Reversal of the direction (press for 5s)

31 Door setting of lower end position

33 Fine correction of upper end position

50 Factory settings

50 - 0 0...80mm lower

50 - 99 0...80mm higher

34 Fine correction of lower end position

50 Factory settings

50 - 0 0...80 mm lower

50 - 99 0...80mm higher

35 Selection of closing edge safety device

Measurement display (press 5seconds)

0 Optical closing edge safety device OSE

1 Electrical safety edge8K2 (default setting)

2 Pressure wave switch with testing

36 Selection of photoelectric sensor

0 Without photoelectric sensor (default setting)

1 2-wire photoelectric sensorLS2

2 4-wire photoelectric sensorLS5 photoelectric

reflection sensor

3 Photoelectric sensorLS2, mounted in frame

4 Photoelectric sensorLS5 photoelectric reflec-

tion sensor mounted in frame

5 4-wire photoelectric sensor with testing

6 4-wire photoelectric sensor in frame with test-

ing

37 Correction of pre-limit switch closing edge safety

25 Correction of pre-limit switch closing edge

safety (default setting)

25 - 0 0...50 mm lower

25 - 99 0...100 mm higher

- - Exit menu

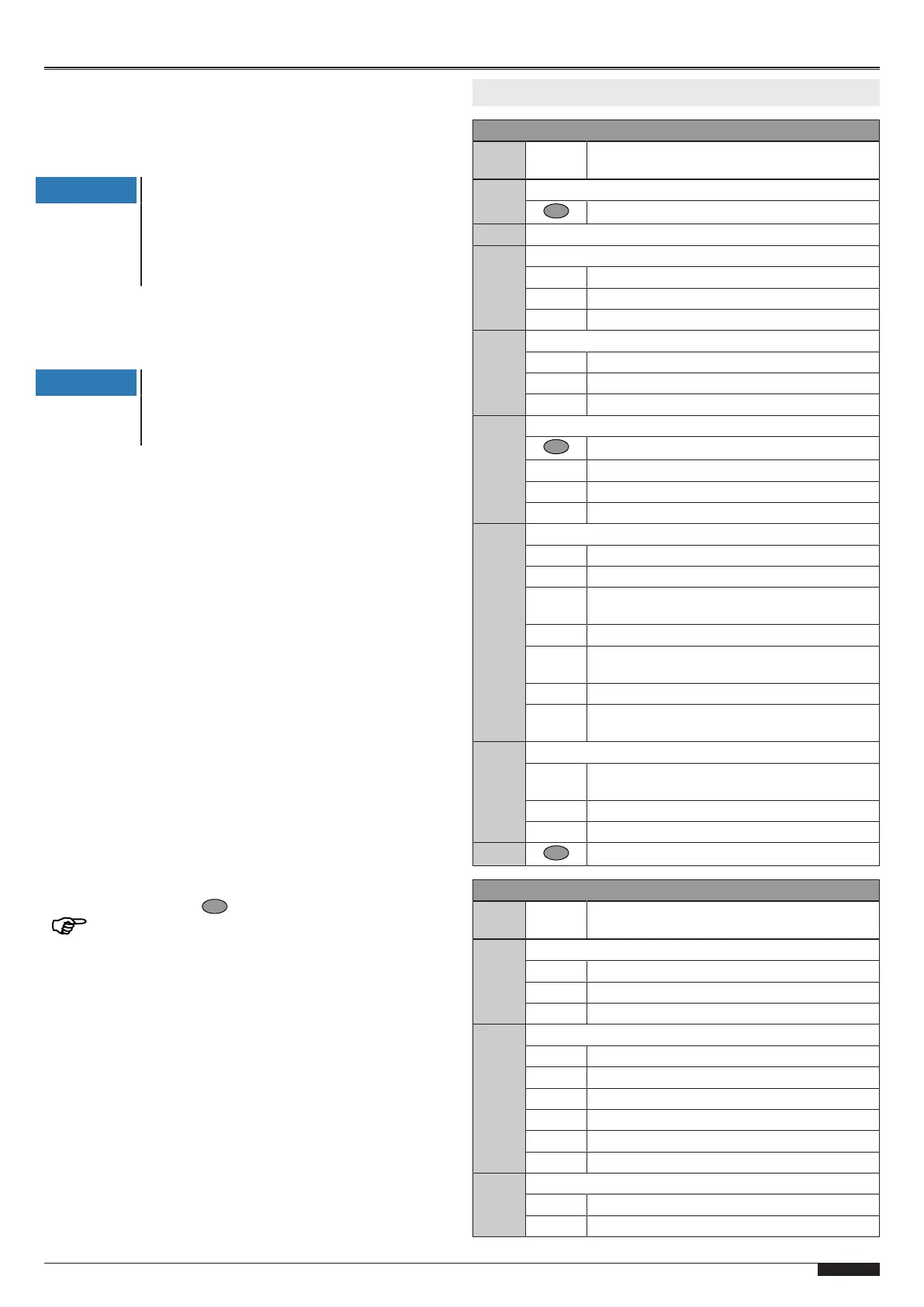

Menu4 Further door settings

Menu

item

Entry Selection

40 Selection of operating mode

0 Dead man OPEN / dead man CLOSE

1 Pulse OPEN / dead man CLOSE

2 Pulse OPEN / pulse CLOSE (default setting)

45 Status relayX3

0 Door close signal

1 Door open signal (default setting)

2 Warning during the process

3 5-minute light

4 Wipe pulse with hand transmitter

5 Wipe pulse

48 Opening force limitation

0 Off (default setting)

1-30 Entry of switch-off force

Loading...

Loading...