13

3S SYSTEM “SOLUTION SAVING

SYSTEM” (OPTIONAL)

The need of an increasing carefulness to

the environment, and to the abuse of pol-

luting elements, such as detergents in the

oorcleaningmachines,hasbroughtusto

the realization of a device which, regard-

less from the capacity to use the machine

by theoperator,keepstheminimumow

of the detergent solution constant, hav-

ing been properly calibrated by an expert

technician.

The best detergent solution amount with

this system will be the one which realizes

theminimumowofdetergentsolution

sufcienttocleancorrectlytheoor.

For this reason the system is called “Solu-

tion Saving System” abbreviated to “3S”

system.

The system is composed by a hydraulic

circuit parallel to the traditional one which

can be enabled or disabled directly from

the instrument board through a 3-position

switch with the following functions:

(1) = Position solution valve with tradi-

tionalfunctioningwithvariablewaterow

that differs by the opening of the solution

valve.

(2) = Position STOP with functioning

withoutow(dryingonly).

(3) = Position 3S with functioning with

optimalxedow.

The hydraulic circuit of the 3S system

is independent and it is provided with

aproperlterwhichhastobecleaned

regularly.

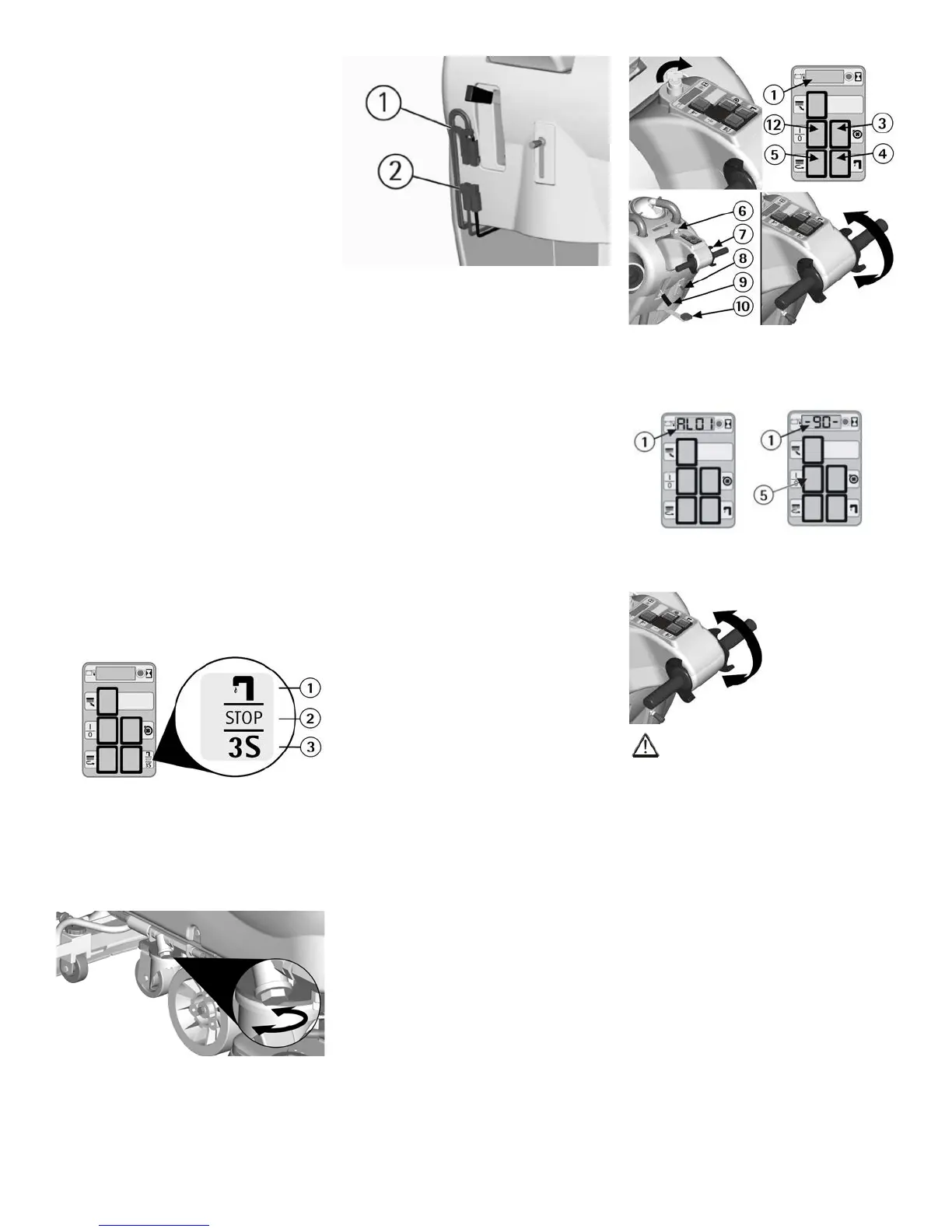

For the cleaning it is necessary to unscrew

theplugasshowninthegureandclean

theinsidelterwithawaterjet.

FLOOR CLEANING

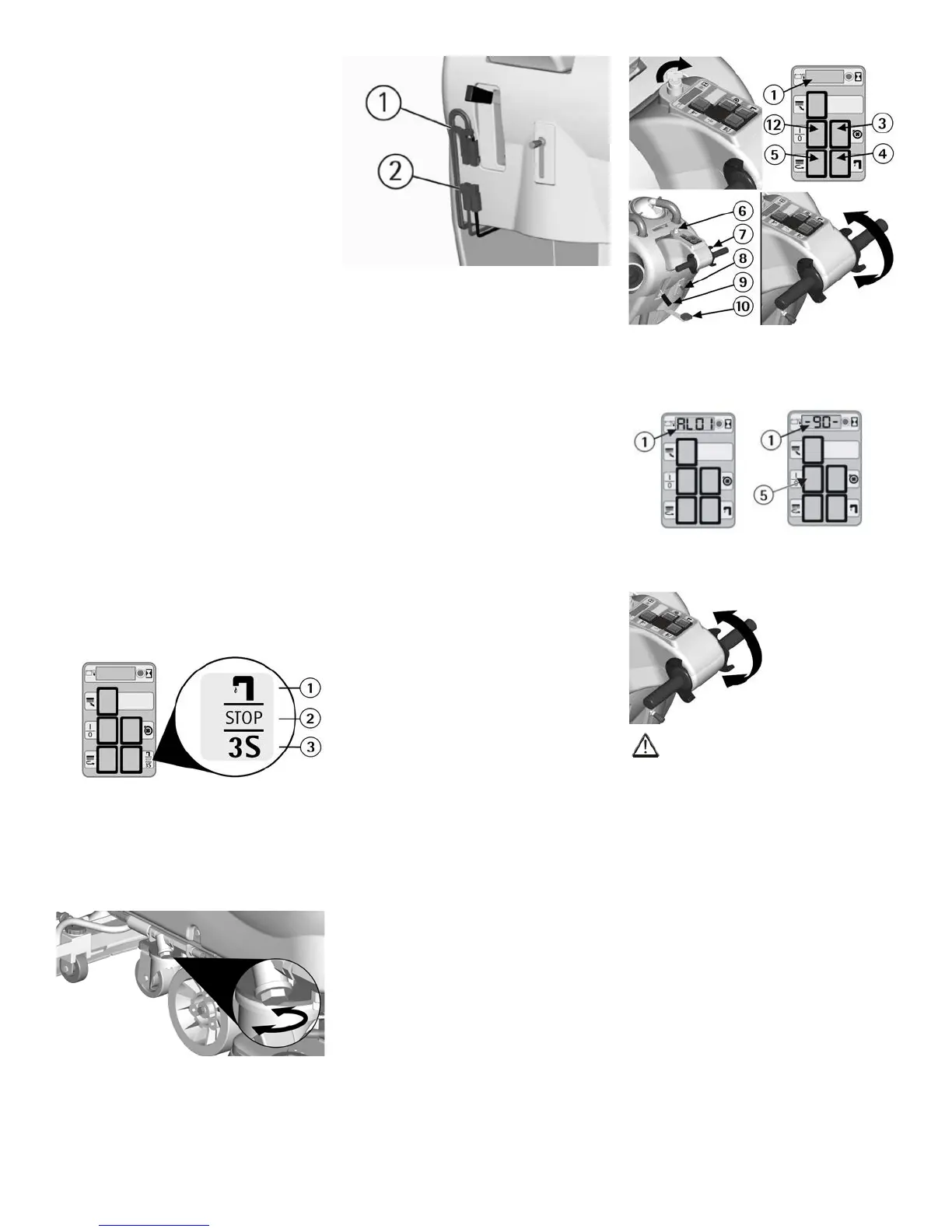

CONNECTION OF THE BATTERIES

TO THE MACHINE

Plug in the batteries connector (1) to the

machine connector (2), placed in the rear

part of the machine.

STARTING OF THE MACHINE

1. Switch on the machine acting upon

the general switch (12). For machines

equipped with key switch (see under "OP-

TIONAL ACCESSORIES”), turn the key

(6) clockwise.

2. Press the brush motor switch (5).

3. Check the battery type and the charge

level on the display (1).

4. Press the suction motor switch (3).

5. Acting upon the solution valve lever

(8) adjust the solution detergent quantity

bringingtheooruniformlywet,avoiding

the leakage of detergent from the splash

guard. Always consider that the correct

quantity of solution detergent depends on

thetypeofoor,dirtinessandmachine

speed.

Acting upon this lever, the indicator on

the instrument board of the open solution

valve (4) will turn on.

For machines optionally equipped with

solenoid valve (see under “OPTIONAL

ACCESSORIES”)theowofdetergent

solution will be activated automatically,

once the solution valve has been opened

through the lever (8), acting upon the

brush activation levers (7). Releasing

theselevers,owwillstopautomatically.

Models equipped with the 3S system (op-

tional), it is necessary to press the suitable

switch to activate the detergent solution

supply by choosing between the traditional

adjustment system through the solution

valveorthesystemofxedoptimumsup-

ply (see under “3S SYSTEM SOLUTION

SAVING SYSTEM”).

6. Acting upon the brush base lifting pedal

(10) lower the brush base.

7. Acting upon the squeegee lifting lever

(9) lower the squeegee.

8. Activating the levers (7) the brush will

start rotating moving the machine a for-

ward movement. The squeegee will start

dryingtheoor.

9.Duringtherstfeet/meterscheckthat

thedetergentsolutionowisappropriate

and that the squeegee adjustment guaran-

tees a perfect drying action.

FORWARD MOVEMENT

By activating the levers (7), the

brush will start rotating resulting in

the machine’s forward movement.

STOP

Releasing the brush activationilevers , the

machine and the brushes will stop.

ATTENTION:

Moving the machine backwards, make

sure that the squeegee is lifted.

ADJUSTMENT OF THE BRUSH

PRESSURE

Through the register (1) placed on the

internal part of the front right wheel, it is

possible to adjust the brush pressure on

the cleaned surface. By turning the wing

nut clockwise the pressure increases, ro-

tating the wing nut counterclockwise, the

pressure decreases. This device allows

amoreefcientcleaningactionalsoon

verydifcultanddirtysurfaces.

Loading...

Loading...