Putthetwoshims(1/8inch[3mm])ontospindle

shaftastheywereoriginallyinstalled.Theseshims

arerequiredtoachievealevelacrosstheentire

widthofthecuttingunits.Slidetheappropriate

numberof1/2inchspacersontothespindleshaft

togetthedesiredheight-of-cut;thenslidethe

washerontotheshaft.

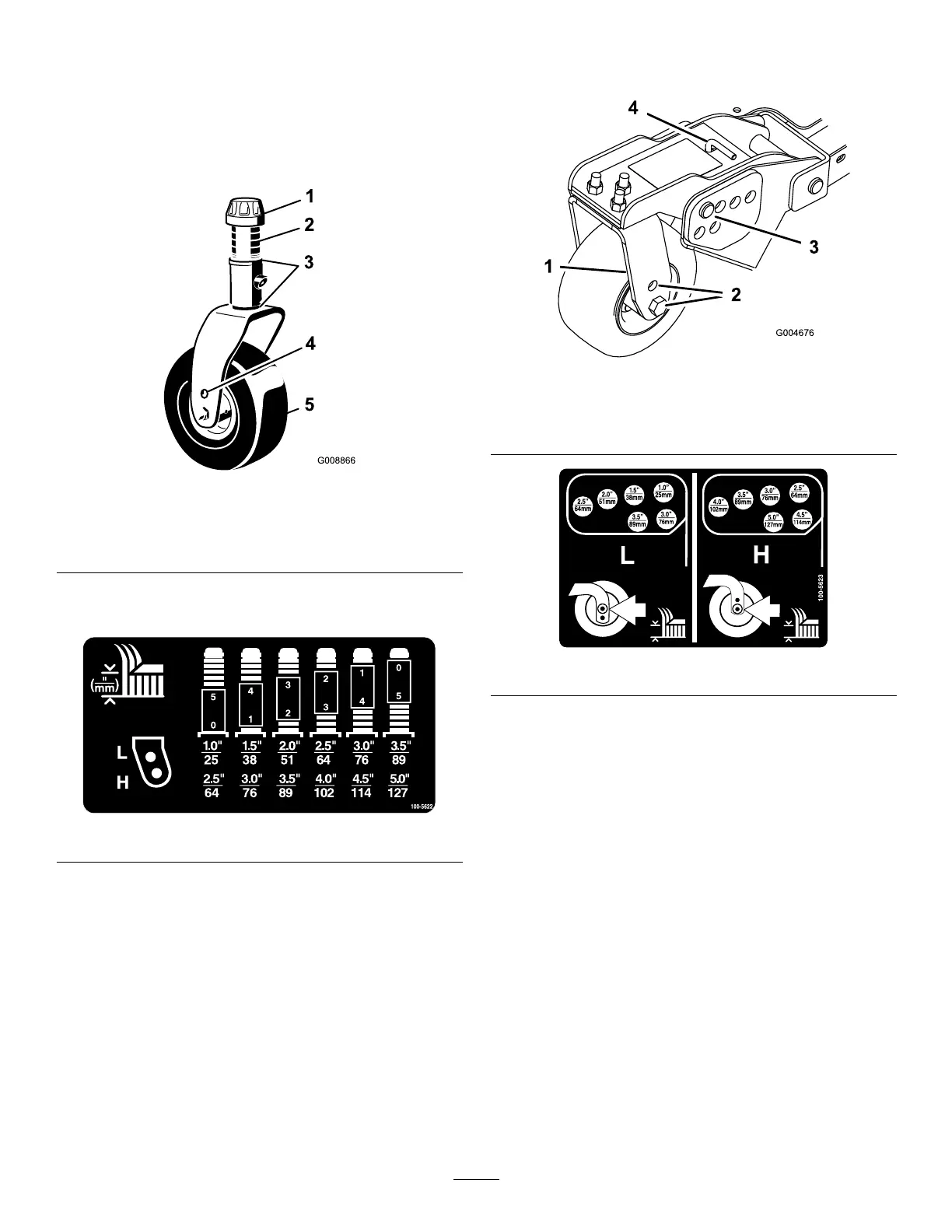

Figure20

1.Tensioningcap4.Toaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

Refertothefollowingcharttodeterminethe

combinationsofspacersforthesetting.

Figure21

3.Pushthecastorspindlethroughthecastorarm.

Installtheshims(asoriginallyinstalled)andthe

remainingspacersontothespindleshaft.Installthe

tensioningcaptosecuretheassembly.

4.Removethehairpincotterandclevispinsfromthe

castorpivotarms(Figure22).

5.Rotatetensionrodtoraiseorlowerpivotarm

untilholesarealignedwithselectedheight-of-cut

bracketholesinthecuttingunitframe(Figure22

andFigure23).

6.Inserttheclevispinsandinstallthehairpincotters.

7.Rotatetensionrodcounterclockwise(ngertight)

toputtensiononadjustment.

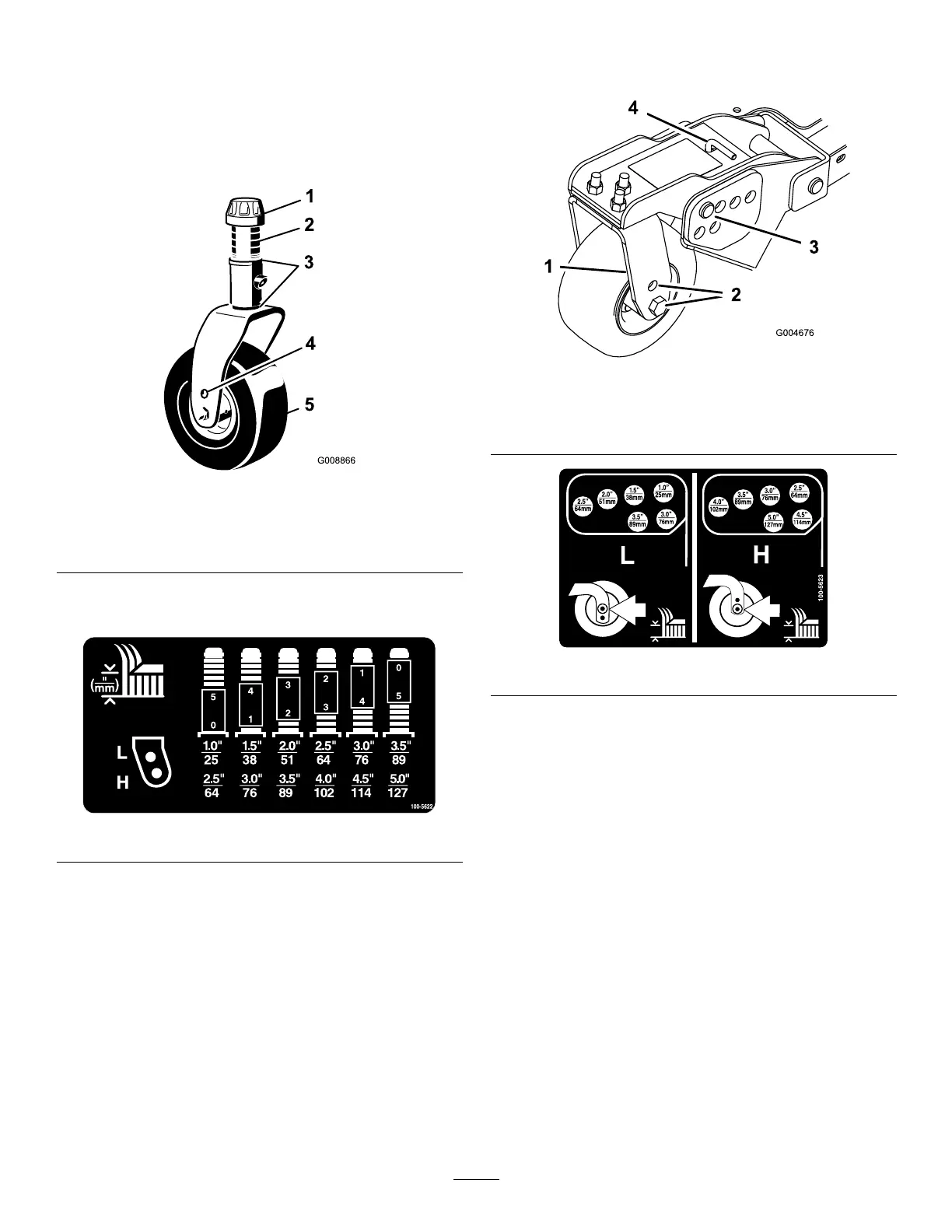

Figure22

1.Castorpivotarm3.Clevispinandhairpin

cotter

2.Axlemountingholes4.Tensionrod

Figure23

8.Removethehairpincottersandclevispinssecuring

thedamperlinkstothecuttingunitbrackets

(Figure24).Alignthedamperlinkholeswiththe

selectedheight-of-cutbracketholesinthecutting

unitframe(Figure25),inserttheclevispins,and

installthehairpincotters.

Important:Thedamperlinklengthshould

neverbeadjusted.Thelengthbetweenthehole

centersshouldbe5-3/8inch(13.7cm).

25

Loading...

Loading...