Figure24

1.Damperlink

Figure25

AdjustingtheSkids

Theskidsshouldbemountedinthelowerposition

whenoperatinginheightofcutsgreaterthan2-1/2

inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

Adjusttheskidsbyremovingtheangeboltandnuts,

positioningthemasdesired,andinstallingthefasteners

(Figure26).

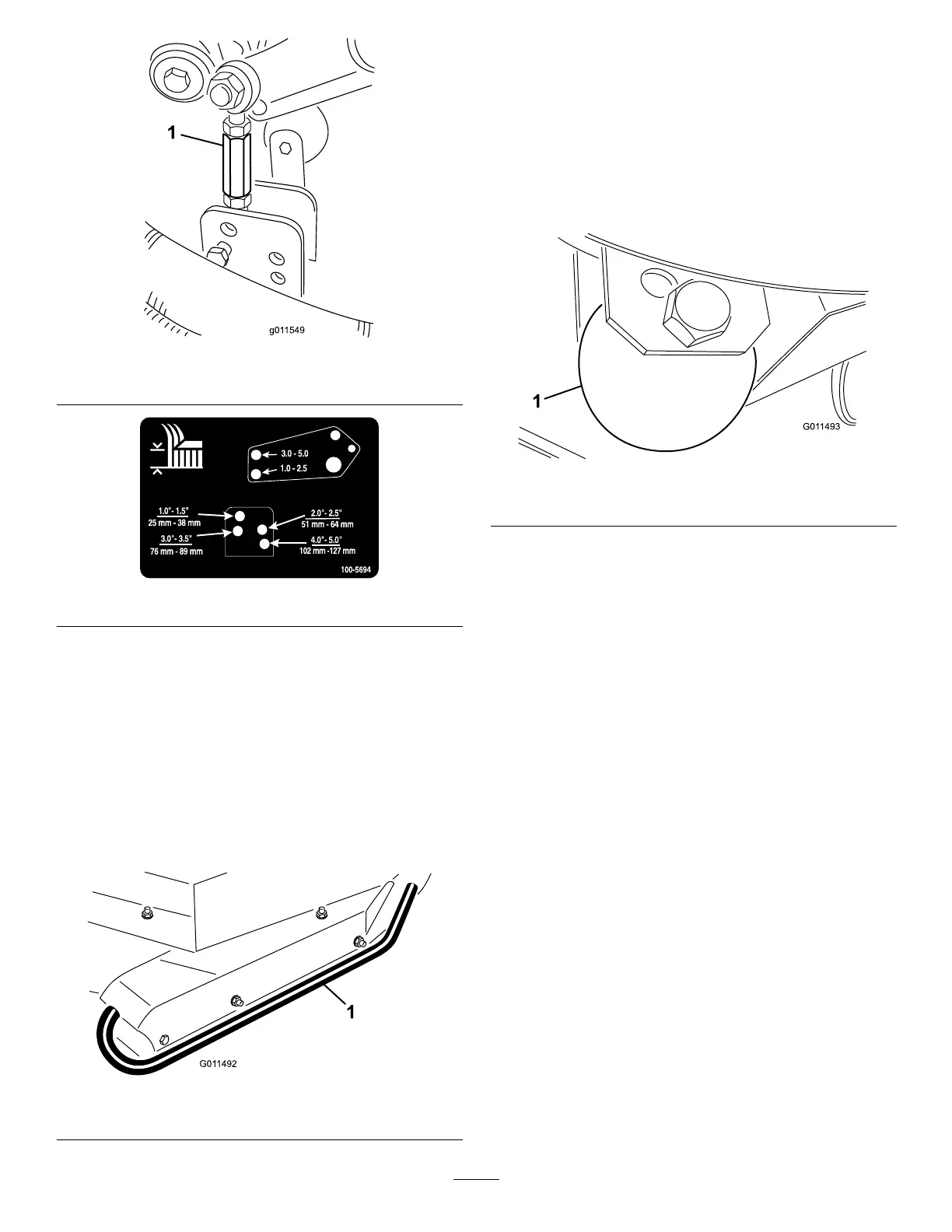

Figure26

1.Skid

AdjustingtheCuttingUnitRollers

Thecuttingunitrollersshouldbemountedinthelower

positionwhenoperatinginheightofcutsgreaterthan

2-1/2inches(64mm)andinthehigherpositionwhen

operatinginheightofcutslowerthan2-1/2inches(64

mm).

1.Removetheboltandnutsecuringthegagewheelto

thecuttingunitbrackets(Figure27).

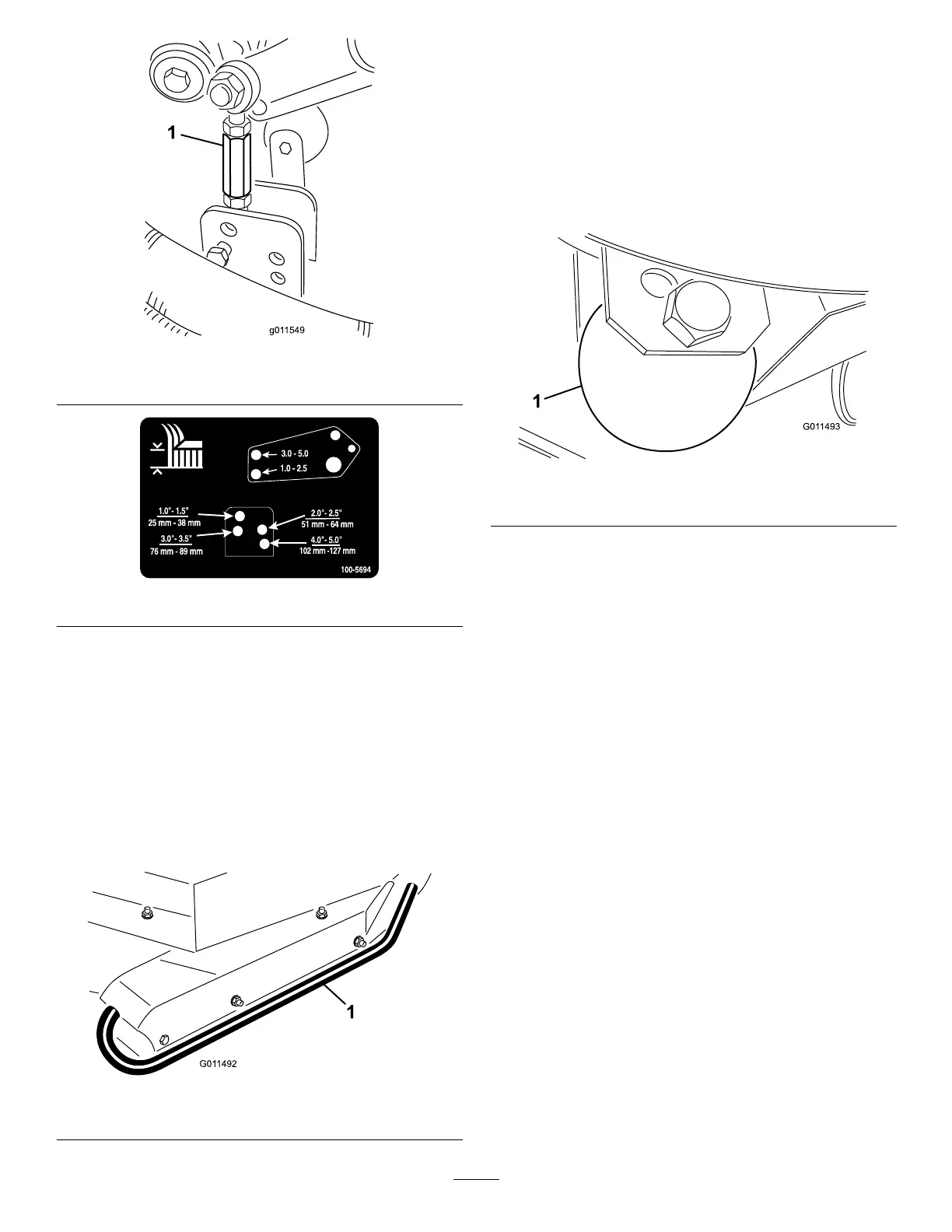

Figure27

1.Gagewheel

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

CorrectingMismatchBetweenCutting

Units

Duetodifferencesingrassconditionsandthe

counterbalancesettingofthetractionunit,itisadvised

thatasampleareaofgrassbecutandtheappearance

checkedbeforeformalcuttingisstarted.

1.Setallcuttingunitstothedesiredheightofcut;

refertoAdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressure

to25-30psi(172-207kPa).

3.Checkandadjustallcastortirepressuresto50psi

(345kPa).

4.Checkchargeandcounterbalancepressures

withengineathighidleusingtestportsdened

inHydraulicSystemsTestPorts.Adjust

counterbalancesettingtobe220psi(1517kPa)

higherthanchargepressurereading.

5.Checkforbentblades;refertoCheckingforaBent

Blade.

6.Cutgrassinatestareatodetermineifallcutting

unitsarecuttingatthesameheight.

7.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga6foot(2m)orlongerstraightedge.

26

Loading...

Loading...