15

OPERATING INSTRUCTIONS

STARTING AND STOPPING

1. Sit on the seat, keep foot off traction pedal. Assure

parking brake is engaged, traction pedal is in

NEUTRAL and cutting unit engagement switch is in the

DISENGAGED position.

2. Turn ignition switch to ON position. When glow plug

indicator light goes off, engine is ready to START.

3. Turn ignition key to START. Release key when

engine starts.

4. To stop, disengage and move all controls to

NEUTRAL and set parking brake. Turn key to OFF and

remove it from switch. Raise and latch all cutting units in

transport position.

PRIMING FUEL SYSTEM (Fig. 15 & 16)

IMPORTANT: The fuel system may need to be

primed when a new engine is started for the first

time, if it runs out of fuel or if maintenance is

performed on the fuel system.

1. Unlatch and raise hood.

2. Insert a 3/16" hose over bleed screw and run other

end into a container to catch fuel.

3. Loosen fuel filter / water separator bleed screw (Fig.

15) a few turns. Pump priming plunger until a steady

stream of fuel comes out of hole in bleed screw. When

fuel stops foaming, tighten the bleed screw during the

downstroke of the priming plunger. Wipe up any spilled

fuel.

Note: Priming fuel filter without opening bleed screw

may damage priming plunger.

4. Pump priming plunger until resistance is felt. Try to

start engine. If engine does not start repeat step 3.

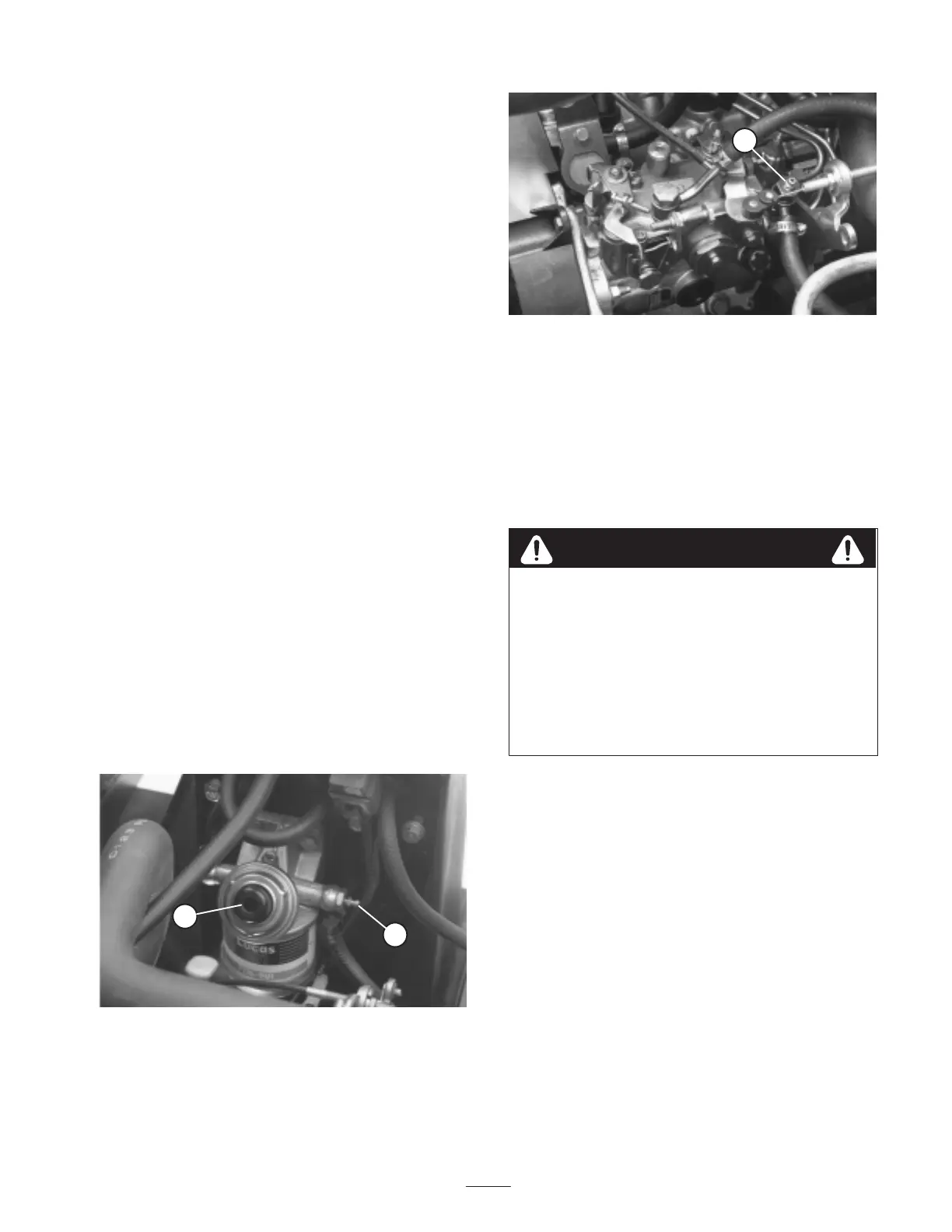

Figure 15

1. Primer Plunger 2. Bleed Screw

1

2

Note: It may be necessary to bleed the air out of the fuel

line between the fuel filter / water separator and the

injection pump. To do this, loosen the fitting on the

injection pump (Fig. 16) and repeat bleeding

procedure.

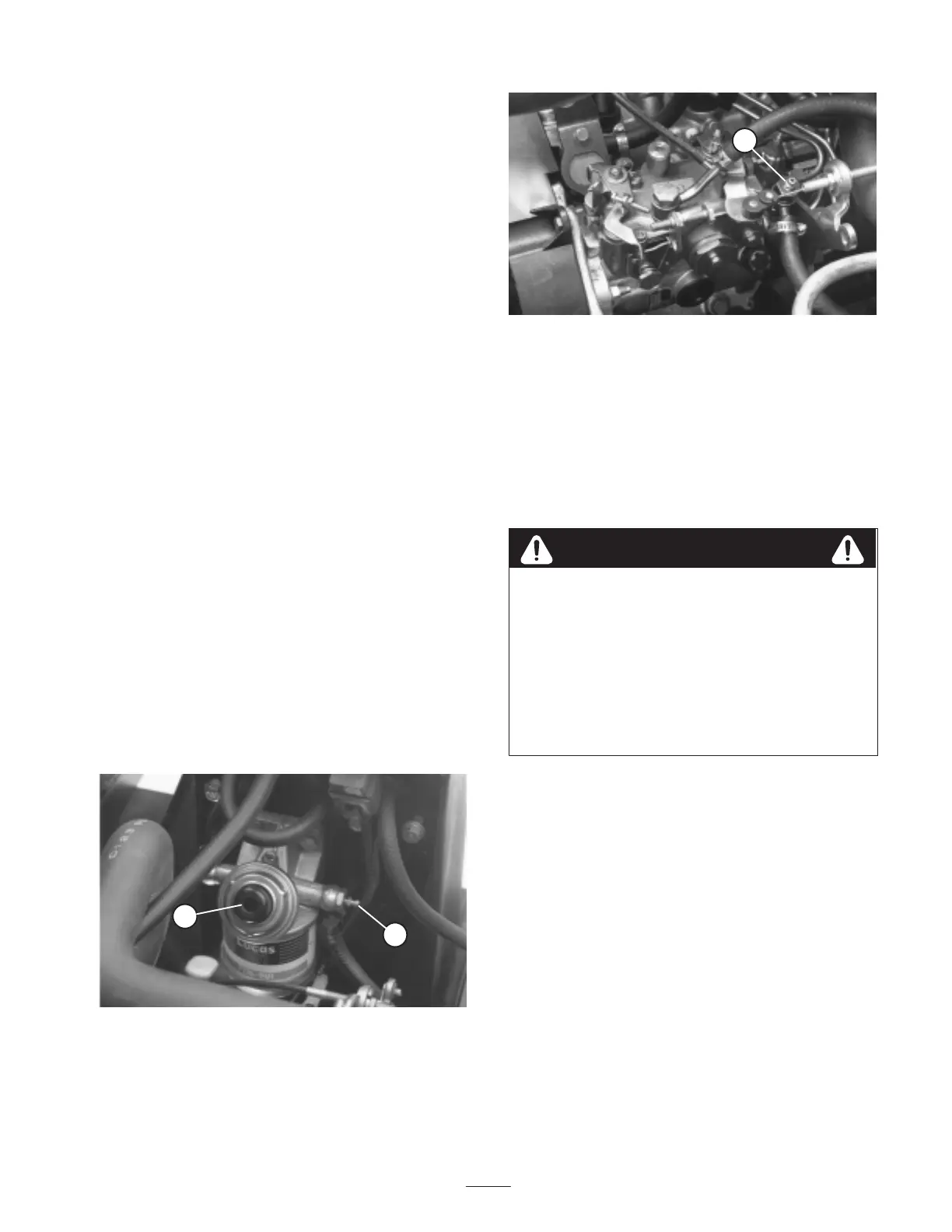

Figure 16

1. Injection Pump Fitting

1

CHECKING INTERLOCK SYSTEM

The purpose of the interlock system is to prevent the

engine from cranking or starting unless the traction

pedal is in NEUTRAL and the cutting unit engagement

switch is DISENGAGED. In addition, the engine will stop

when the cutting unit engagement switch is engaged or

traction pedal is depressed with operator off the seat, or

if the parking brake is engaged.

If safety interlock switches are disconnected or

damaged, the machine could operate unexpectedly

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

• Replace switches every two years regardless of

whether they are operating properly or not.

Caution

1. In a wide open area free of debris and bystanders,

lower cutting unit to the ground. Stop engine.

2. Move cutting unit engagement switch to

DISENGAGED position and remove foot from traction

pedal so it is fully released.

3. Rotate the ignition key to START. Engine should

start. If engine starts, proceed to step 4. If engine does

not start, there may be a malfunction in the interlock

system.

4. Raise off the seat and engage the cutting unit

engagement switch while the engine is running. The

engine should stop within 2 seconds. If engine stops,

the switch is operating correctly; thus, continue

operation. If engine does not stop, there is a

malfunction in the interlock system.

5. Sit on the seat, engage the parking brake and start

the engine. Move the traction pedal out of the neutral

position. The engine should kill. If the engine does not

kill, there is a malfunction in the interlock system that

should be corrected before beginning operation.

Loading...

Loading...