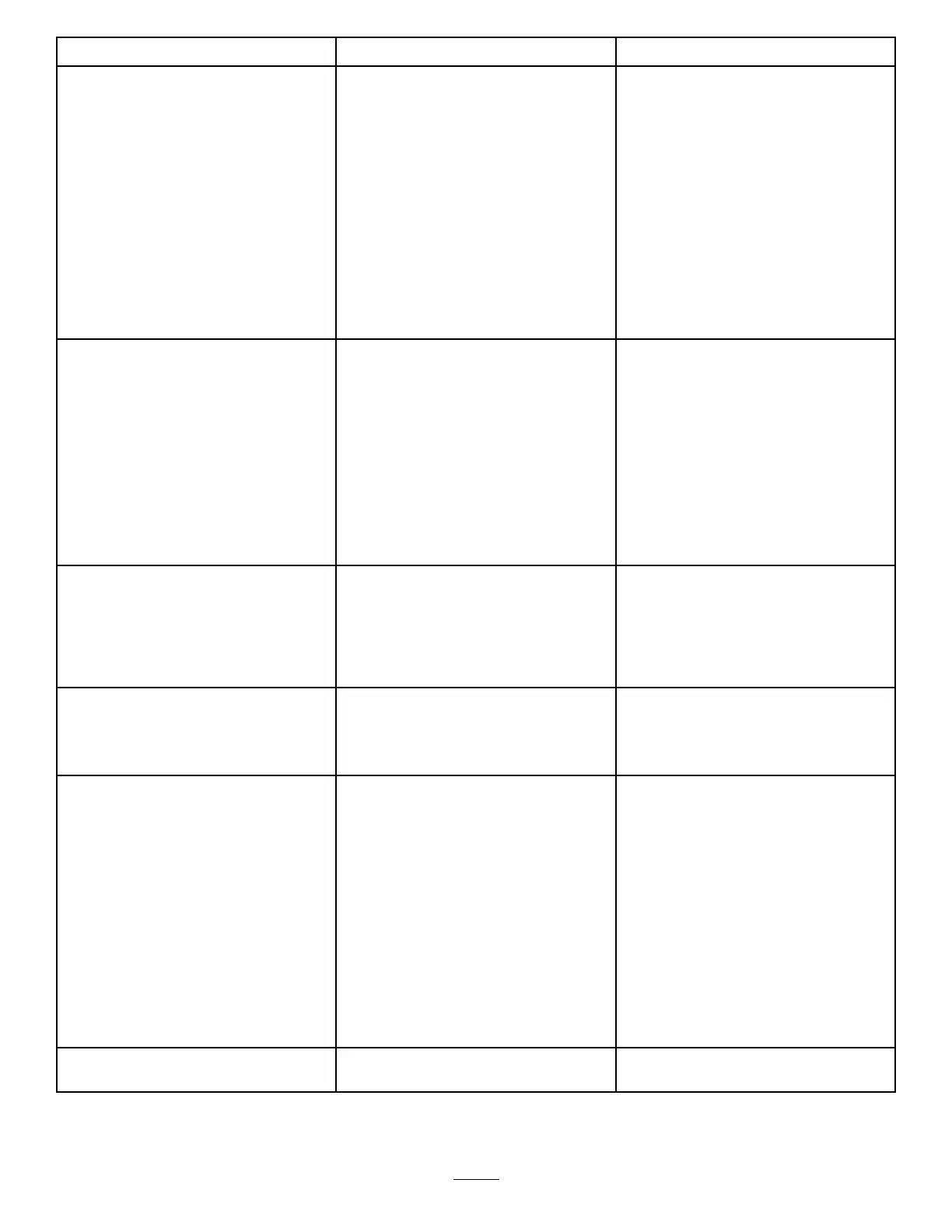

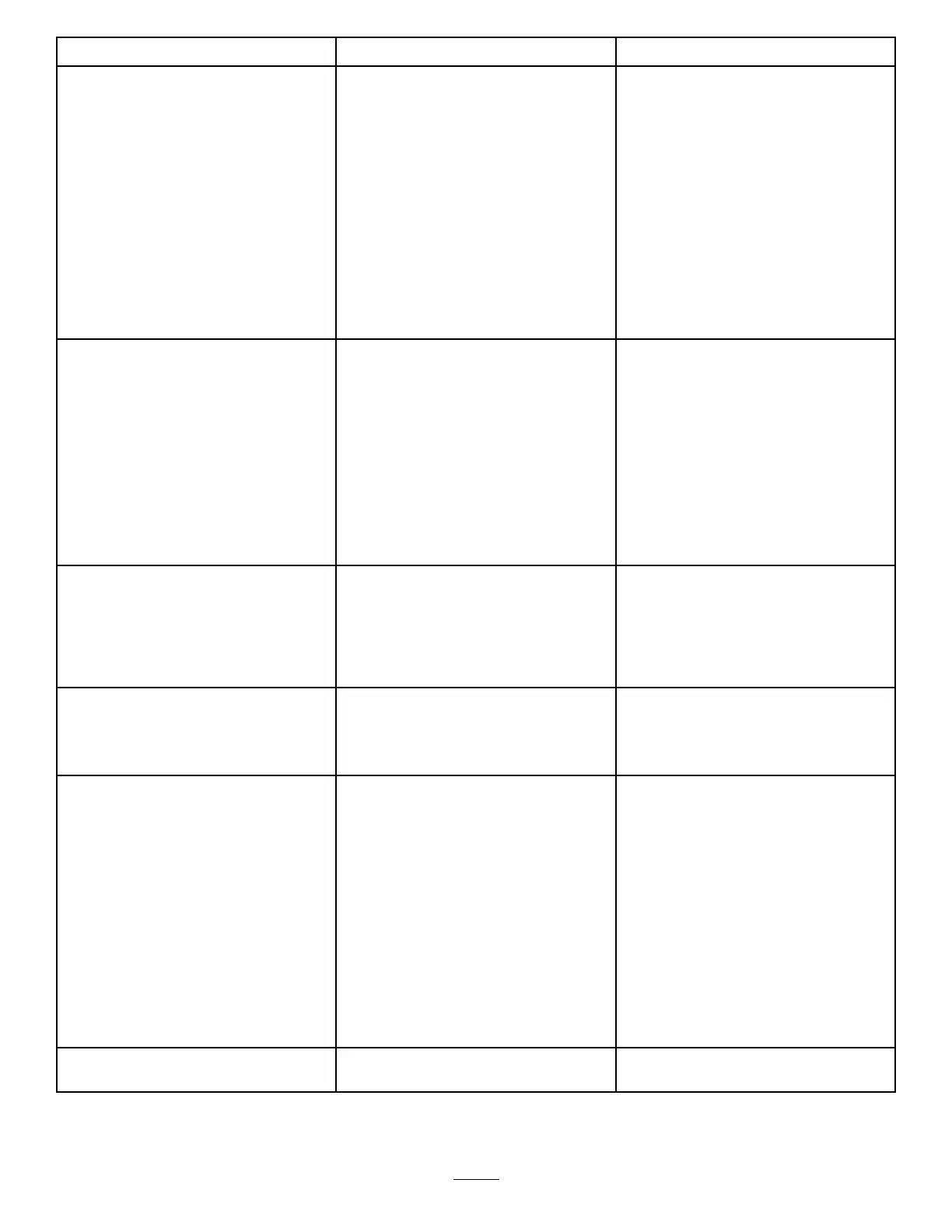

Problem

PossibleCauseCorrectiveAction

1.Faultypump

1.Identifynoisypumpandserviceor

replace

2.Faultymotor

2.Identifynoisymotorandserviceor

replace

3.Airleakingintosystem

3.Tightenorreplacehydraulicttings

particularlyinsuctionlines

4.Suctionstrainerblockedordamaged4.Cleanandreplacesuctionstraineror

renewasnecessary

5.Excessiveoilviscosityduetocold

conditions

5.Allowsystemtowarmup

6.Lowreliefvalvesetting6.Havereliefvalvecleanedandpressure

checked.Consultyourauthorized

dealer

Excessivenoiseinhydraulicsystem

7.Lowhydraulicoillevel7.Fillhydraulicoilreservoirtocorrect

level

1.Wornpumpormotor1.Replaceasnecessary

2.Lowhydraulicoillevel2.Fillhydraulicoiltanktocorrectlevel

3.Incorrectoilviscosity3.Replaceoilinhydraulictankwith

correctviscositygradeoil

4.Oillterelementblocked4.Changelterelement

5.Faultypressurereliefvalve5.Havereliefvalvecleanedandpressure

checked.Consultyourauthorized

dealer

6.Overheating

6.Reduceworkratei.e.increaseheight

ofcutorreduceforwardspeed

Afterinitialsatisfactoryoperationmachine

losespower

7.Leaksonsuctionhose

7.Checkandtightenttings.Replace

hoseifnecessary.

1.Liftcylindersealfailure

1.Replaceseals

2.Pressurereliefvalvejammedopenor

wronglyset

2.Havereliefvalvecleanedandpressure

checked.Consultyourauthorized

dealer

3.Defectivecontrolvalve3.Overhaulcontrolvalve

Cuttingunitfailstoliftoutofwork

4.Mechanicalblockage4.Removeblockage

1.Tightnessinpivots1.Releaseandgreaseasnecessary

2.Moweroperatedin‘hold’position2.Movepositioncontrolswitchto‘down

/oat’position

Cuttingunitdoesnotfollowground

contours

3.Weighttransfersettoohigh3.Reduceweighttransfer

1.Faultyseatsensorswitch

1.Checkmechanicalandelectrical

operationofswitch

2.Lowoillevel2.Fillhydraulicoilreservoirtocorrect

level

3.Sheareddriveshaft3.Checkmotorandcylinderdriveshafts

andreplaceifnecessary

4.Pressurereliefvalvejammedopenor

wronglyset

4.Havereliefvalvecleanedandpressure

checked.Consultyourauthorized

dealer

5.Cuttingunitblade(s)jammed5.Clearasnecessary

6.Cuttingunitcontrolvalveinthe‘off’

positioncausedbydefectivecontrol

valve

6.Overhaulcontrolvalve

Cuttingunitfailstostartup

7.Cuttingunitcontrolvalveinthe‘off’

positioncausedbyelectricalfault

7.Haveelectricalsystemchecked

Bladesrotateinwrongdirection1.Hosesconnectedwrong

1.Checkhydrauliccircuitandreconnect

asnecessary

48

Loading...

Loading...