2

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressurefornon-cabmodelsis103kPa(15psi)inthefront

tiresand172kPa(25psi)inthereartires.Ifacabisinstalled

onthemachine,thefrontandreartiresshouldbeinatedto

172kPa(25psi).

3

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicSystem(page

44).

2.Checktheengineoillevelbeforestartingtheengine,

refertoCheckingtheEngine-OilLevel(page34).

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page39).

4

InstallingtheDriveShafttoan

OptionalMowerDeckorQAS

Partsneededforthisprocedure:

1

Driveshaft

4

Screw,5/16x1–3/4inch

4

Locknut,5/16inch

2

Rollpin,3/16x1–1/2inch

Procedure

Note:PTOdriveshaftinstallationiseasierifthemachineis

positionedonahoist.

1.Parkmachineonalevelsurface,stopengine,engage

parkingbrakeandremovekeyfromtheignitionswitch.

WARNING

Donotstarttheengineandengagethe

PTOswitchwhenthePTOdriveshaftis

disconnectedfromthecuttingdeck.Ifthe

engineisstartedandthePTOshaftisallowed

torotate,seriouspersonalinjuryandmachine

damagecouldresult.BeforethePTOdrive

shaftisdisconnectedfromthecuttingdeck,

disconnectPTOsolenoidcoilconnector

fromwireharnesstopreventunintentional

engagementofthePTOclutch.

2.TopreventtheunintentionalengagementofthePTO

clutch,disconnectthewireharnesselectricalconnector

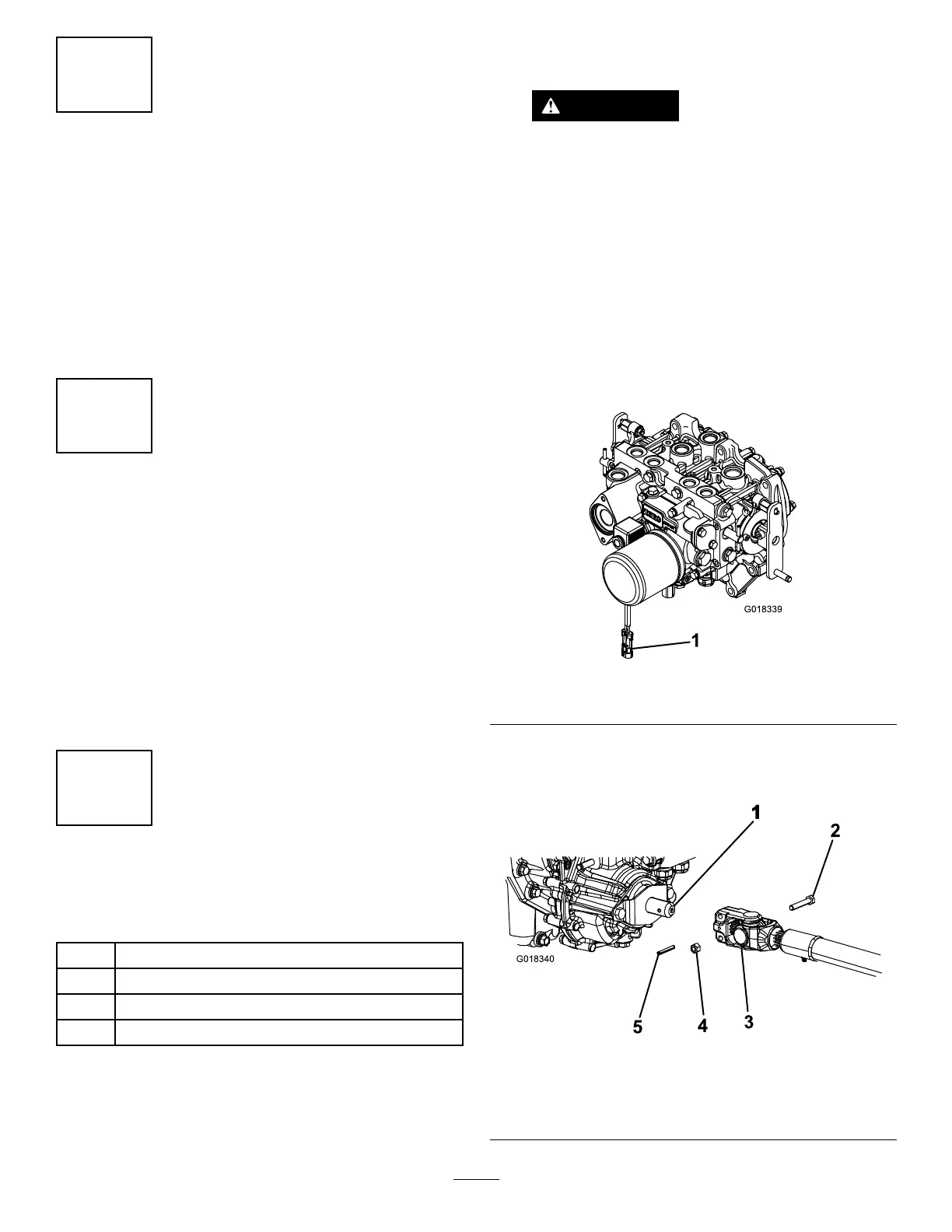

fromthePTOsolenoidvalvecoilconnector(Figure4).

Figure4

1.Wireharnesselectricalconnector

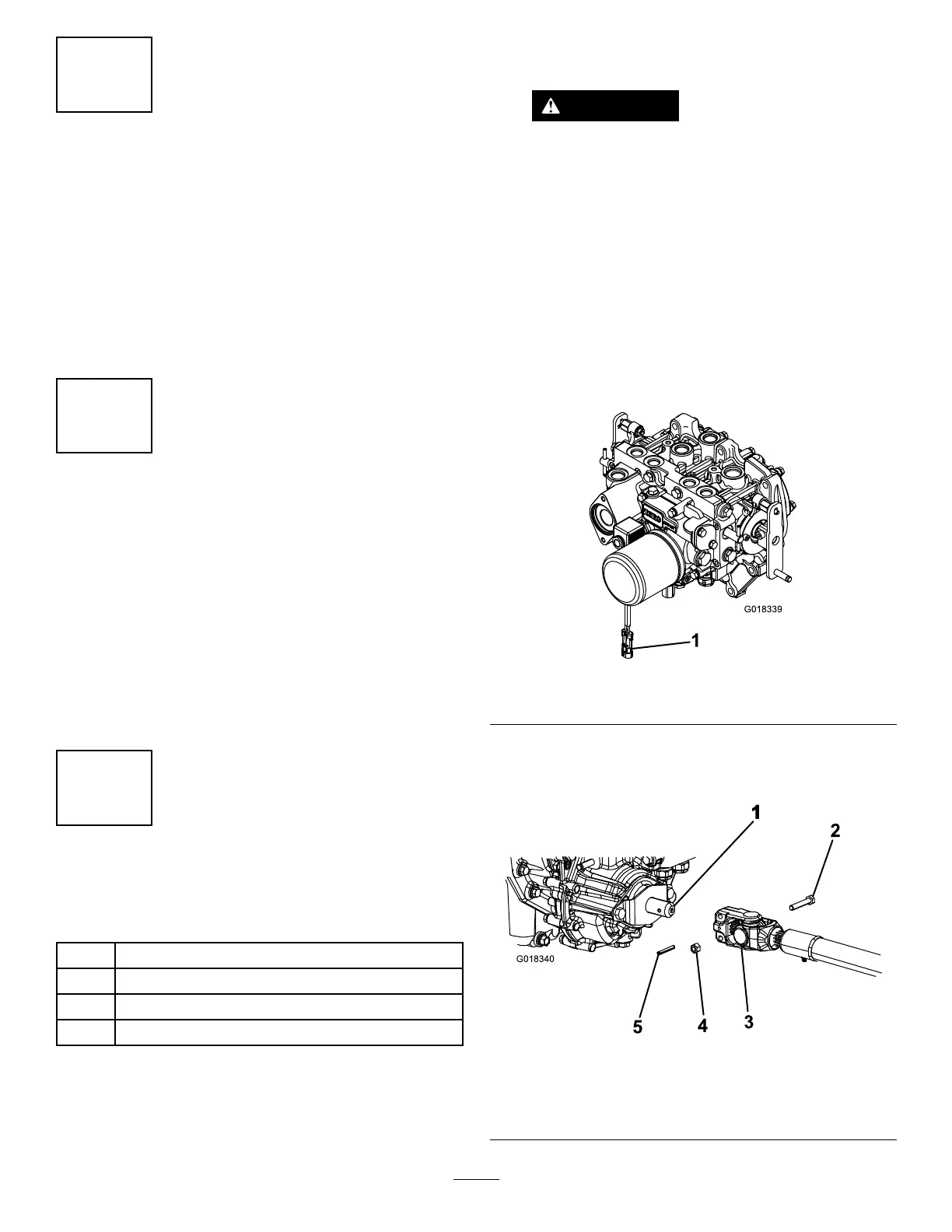

3.PositionthePTOdriveshaftunderthefrontofthe

machine.Makesurethatthedriveshaftslipshaftyoke

(Figure5)istowardthetransmissionPTOshaft.

Figure5

1.Transmissiondriveshaft

4.Locknut

2.Capscrew

5.Rollpin

3.PTOshaft

13

Loading...

Loading...