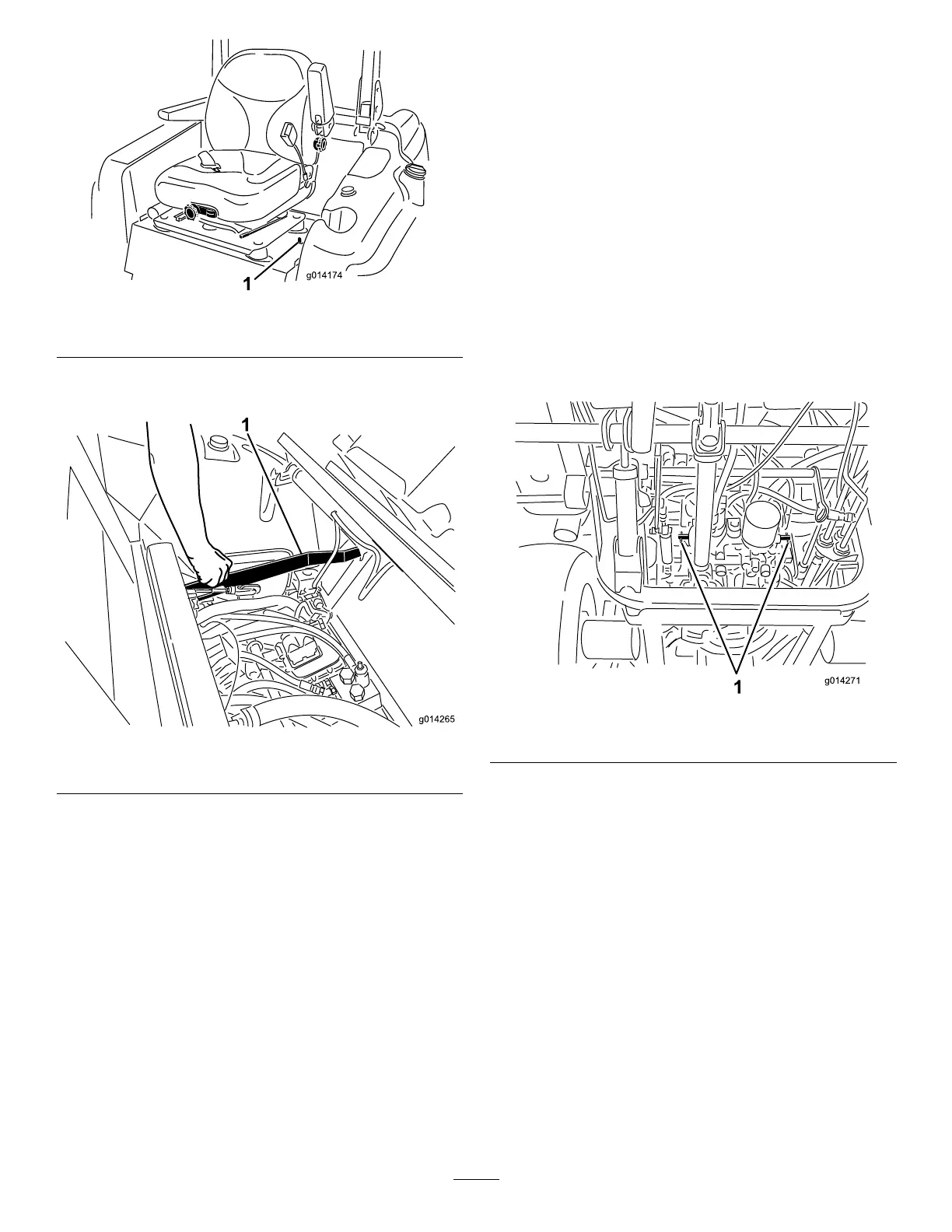

Figure26

1.Seatlatch

2.Tolowertheseat,pullupontheseatlatchreleasebar

andlowertheseatintothelockedposition.

Figure27

1.Seatlatchreleasebar

PushingtheMachinebyHand

Ifthemachinestalls,runsoutoffuel,etc.youmayneedto

pushit.Todoso,yourstneedtoopenbothofthehydraulic

by-passvalves.

Important:Alwayspushthemachinebyhandand

neveralongdistance.Nevertowthemachinebecause

hydraulicdamagemayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO),turntheignition

keytooffandapplytheparkingbrake.

2.Removethekeyfromtheignitionswitch.Both

by-passvalvesmustbeopened.

3.Lifttheseat.

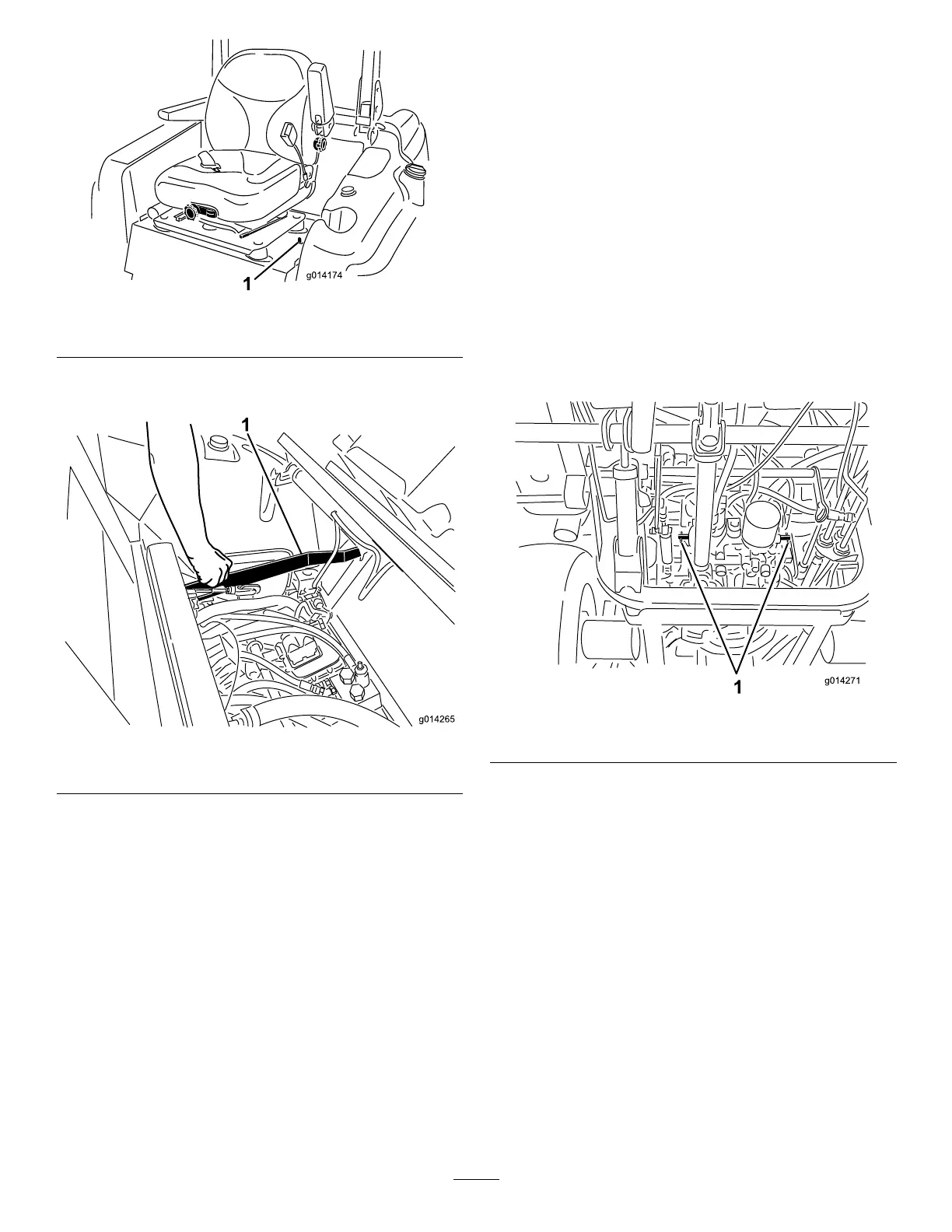

4.Rotateeachby-passvalvecounterclockwise1turn

(Figure28).

Thisallowshydraulicuidtoby-passthepump

enablingthewheelstoturn.

Important:Donotrotatetheby-passvalvesmore

than1turn.Thispreventsvalvesfromcomingout

ofthebodyandcausinguidtorunout.

5.Disengagetheparkingbrakebeforepushing.

ChangingtoMachineOperation

Rotateeachby-passvalveclockwise1turnandhandtighten

them(torqueofapproximately8N-m(71in-lb)(Figure28).

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveproperlyunlesstheby-passvalves

areturnedin.

Figure28

1.By-passvalves

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(Figure29).Thelowerrearsectionof

thetractorframeextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafullwidth

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampstosimulatea

fullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

Figure29).Asteeperanglemaycause

machinecomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

30

Loading...

Loading...