ControlsSystem

Maintenance

Adjustingthe

Control-HandlePosition

Thereare2heightpositionsforthecontrol

levers—highandlow.Removetheboltstoadjustthe

heightfortheoperator.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

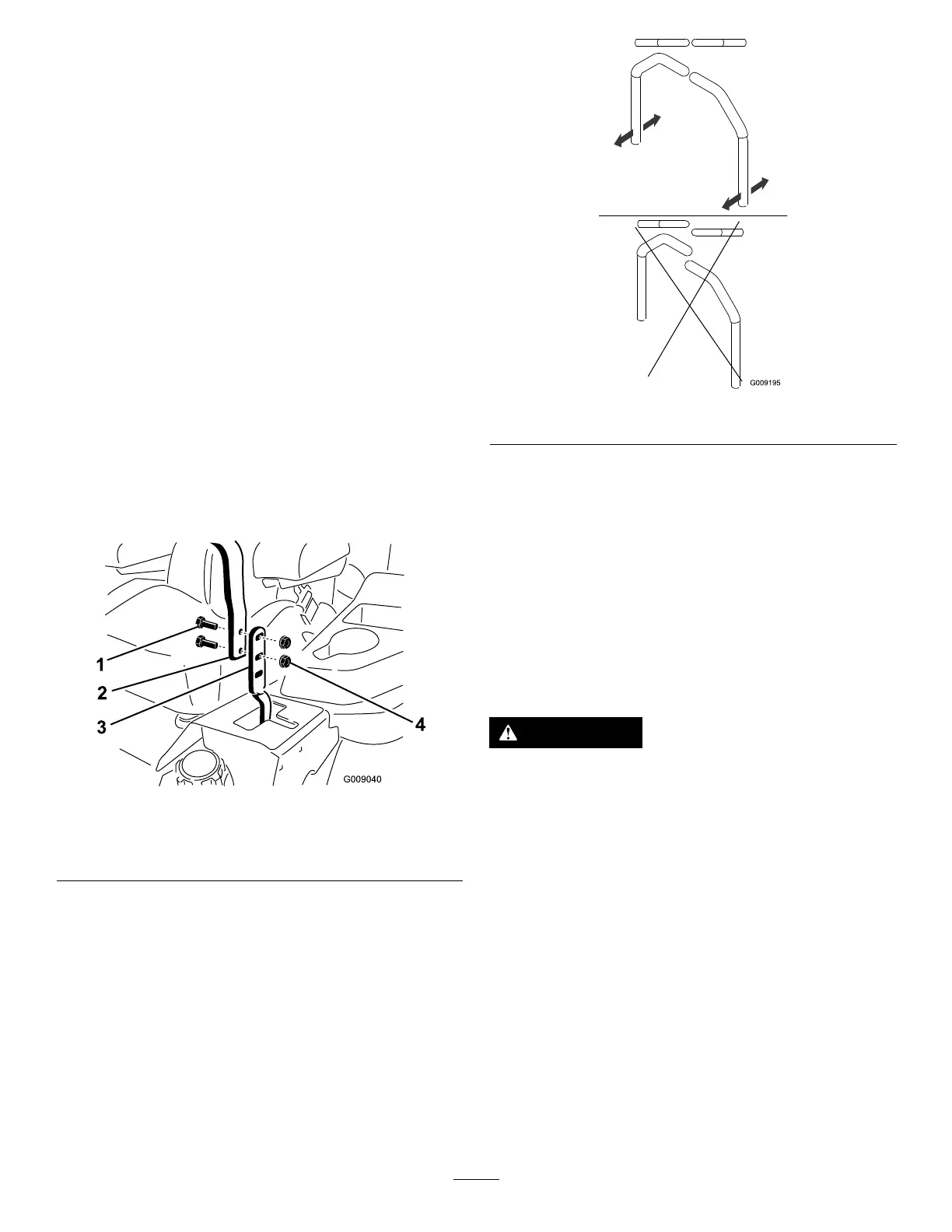

3.Loosentheboltsandangenutsinstalledinthe

levers(Figure63).

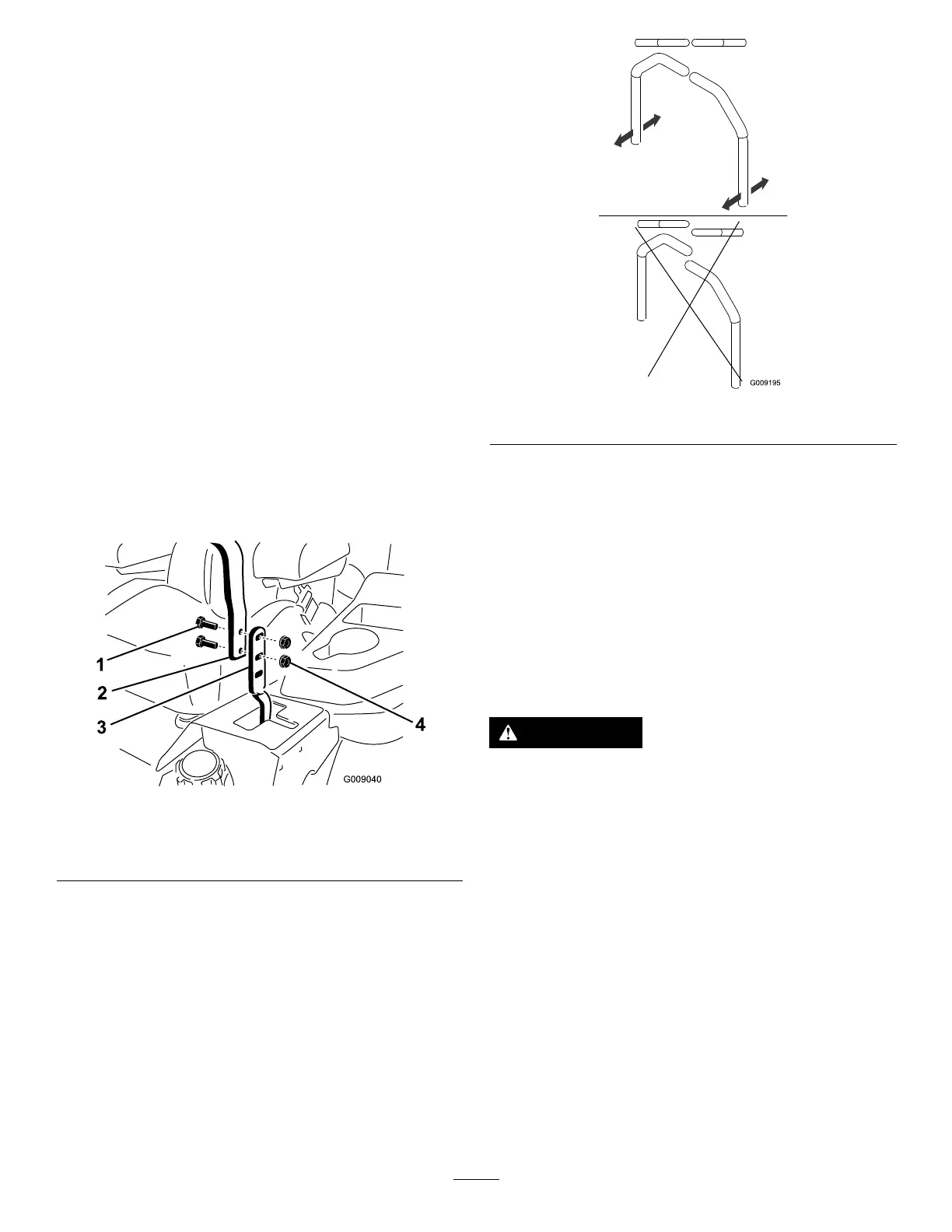

4.Aligntheleversinthefront-to-rearpositionby

bringingtheleverstogethertotheNEUTRAL

position,andslidethemuntiltheyarealigned,

thentightenthebolts(Figure64).

g009040

Figure63

1.Bolt

3.Controllever

2.Handle4.Nut

g009195

Figure64

5.Iftheendsofthelevershitagainsteachother,

repeatthisprocedure.

Adjustingthe

Motion-ControlLinkage

Locatedoneithersideofthefueltank,belowtheseat

arethepump-controllinkages.Rotatingthepump

linkagewithawrench(1/2inch)allowsnetuning

adjustmentssothatthemachinedoesnotmovein

neutral.Anyadjustmentsshouldbemadeforneutral

positioningonly.

WARNING

Toadjustthemotioncontrol,youmustrun

theengineandturnthedrivewheels.Contact

withmovingpartsorhotsurfacesmaycause

personalinjury.

Keepyourngers,hands,andclothingclear

ofrotatingcomponentsandhotsurfaces.

1.Priortostartingtheengine,pushthedeck-lift

pedal,andremovetheheight-of-cutpin.

2.Lowerdecktotheground.

3.Raisetherearofmachineupandsupportitwith

jackstands(orequivalentsupport).

Note:Raisethemachinejusthighenoughto

allowthedrivewheelstoturnfreely.

4.Removetheelectricalconnectionfromtheseat

safetyswitch,locatedunderthebottomcushion

oftheseat.

Note:Theswitchisapartoftheseatassembly.

53

Loading...

Loading...