RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseserious

injury.

Wearglovesorwrapsharpedgesoftheblade

witharag.

1.Holdthebladeendusingaragorthicklypadded

glove.

2.Removethebladebolt,springdiskandblade

fromthespindleshaft(Figure82).

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecould

bethrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blade.

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure80).Maintainthe

originalangle.Thebladeretainsitsbalanceif

thesameamountofmaterialisremovedfrom

bothcuttingedges.

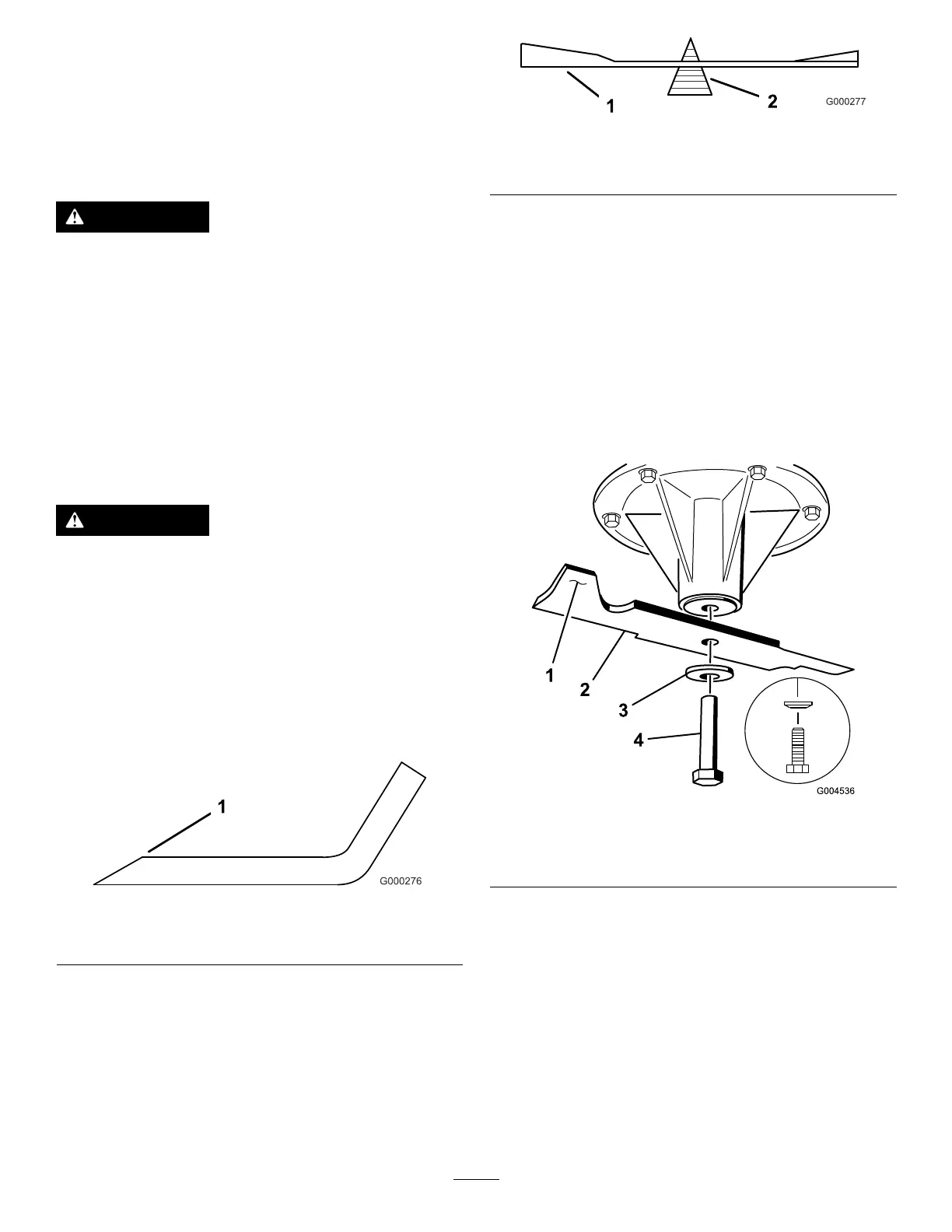

g000276

Figure80

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingiton

abladebalancer(Figure81).Ifthebladestays

inahorizontalposition,thebladeisbalanced

andcanbeused.Ifthebladeisnotbalanced,

lesomemetalofftheendofthesailareaonly

(Figure82).Repeatthisprocedureuntilthe

bladeisbalanced.

g000277

Figure81

1.Blade2.Balancer

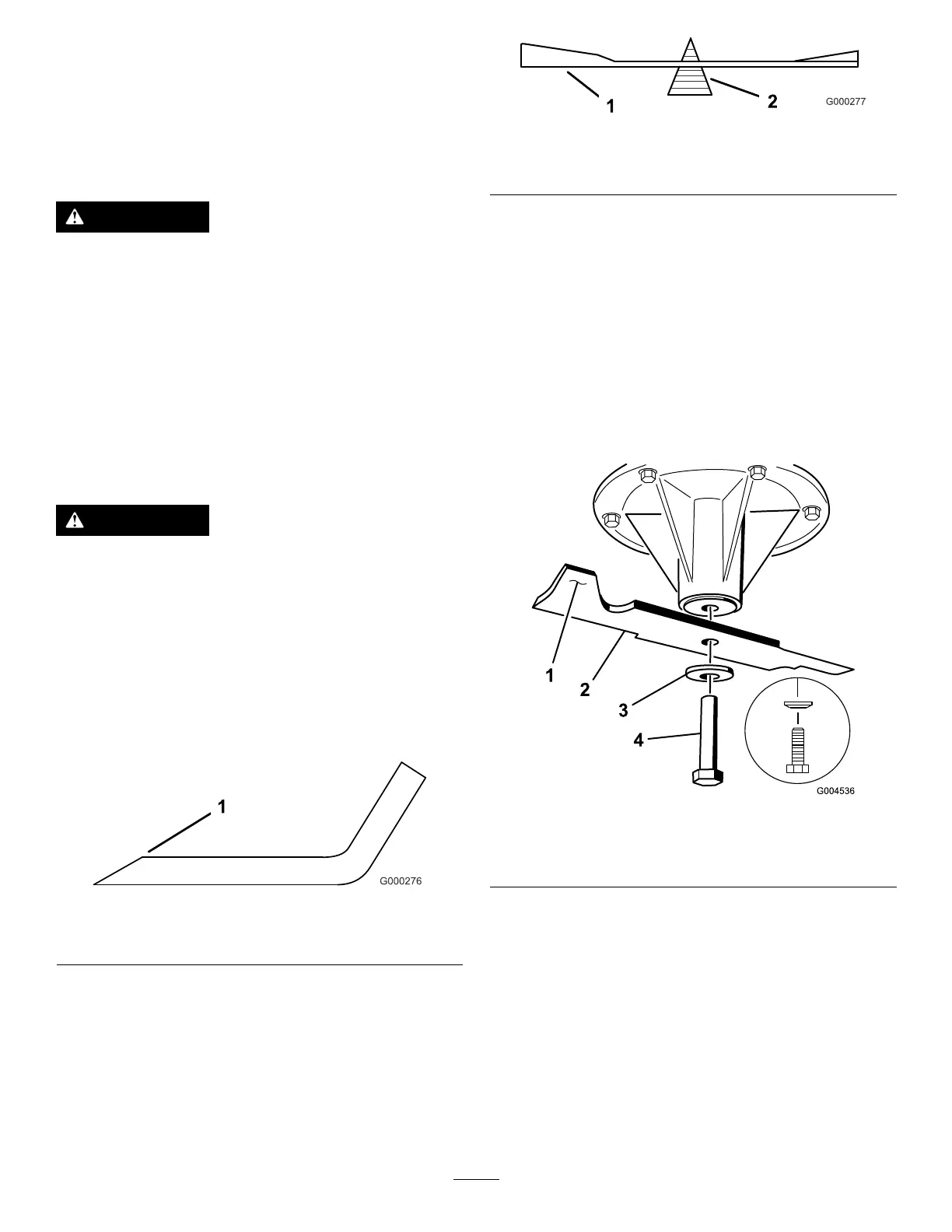

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

82).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installthecurvedwasherandbladebolt.The

curvedwasherconemustbeinstalledtoward

thebolthead(Figure82).T orquethebladebolt

to115to150N∙m(85to110ft-lb).

g004536

Figure82

1.Sailareaofblade3.Curvedwasher

2.Blade4.Bladebolt

61

Loading...

Loading...