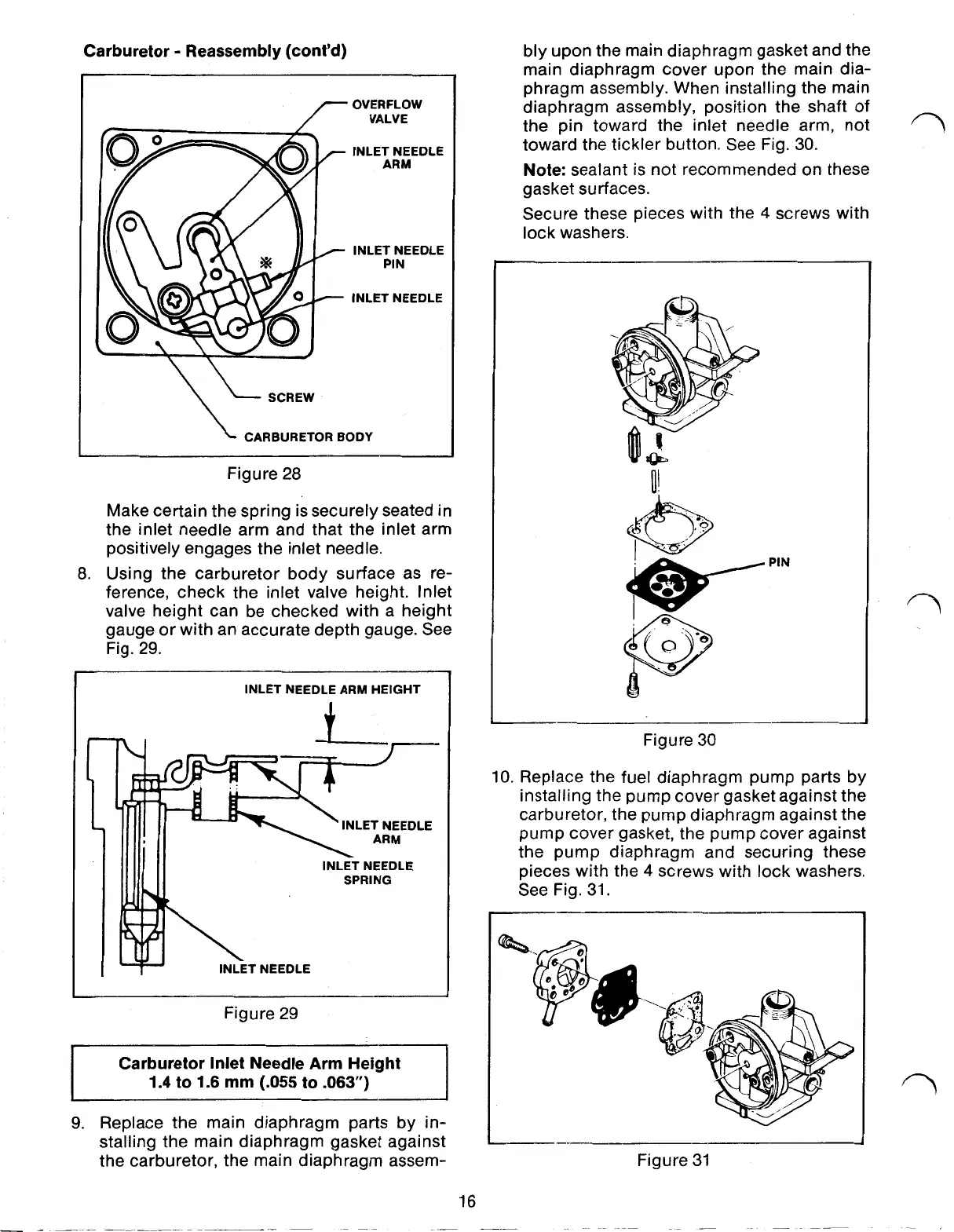

Carburetor Reassembly (cont'd)

VALVE

OVERFLOW

INLET NEEDLE

ARM

INLET NEEDLE

PIN

INLET NEEDLE

SCREW

CARBURETOR BODY

Figure 28

Make certain the spring is securely seated in

the inlet needle arm and that the inlet arm

positively engages the inlet needle.

8. Using the carburetor body surface as re-

ference, check the inlet valve height. Inlet

valve height can be checked with a height

gauge or with an accurate depth gauge. See

Fig.

29.

INLET NEEDLE ARM HEIGHT

t

INLET NEEDLE

INLET NEEDLE

Figure 29

Carburetor Inlet Needle Arm Height

1.4 to 1.6 mm

(.055

to .063")

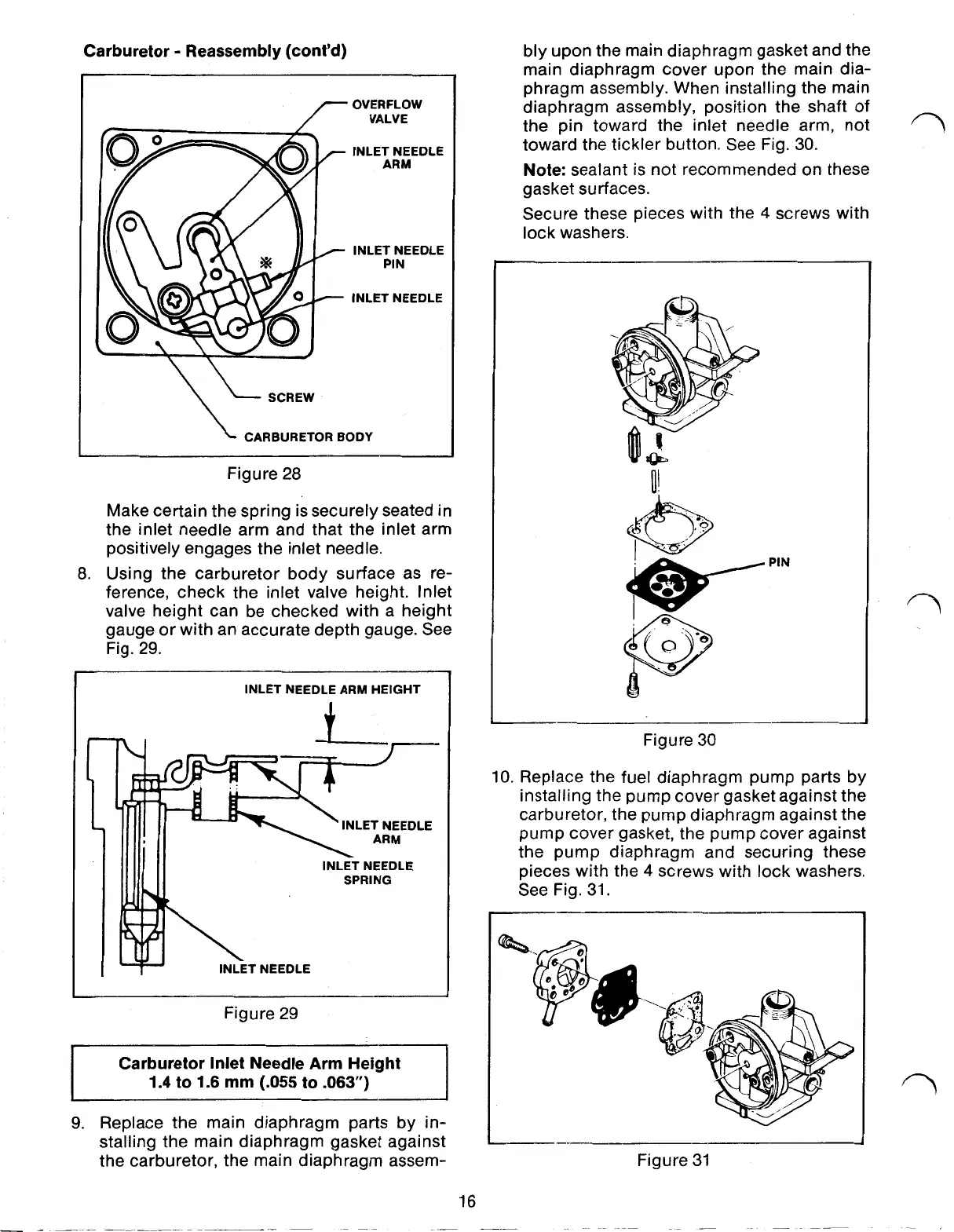

9.

Replace the main diaphragm parts by in-

stalling the main diaphragm gasket against

the carburetor, the main diaphragm assem-

16

bly upon the main diaphragm gasket and the

main diaphragm cover upon the main dia-

phragm assembly. When installing the main

diaphragm assembly, position the shaft of

the pin toward the inlet needle arm, not

toward the tickler button. See Fig. 30.

Note:

sealant is not recommended on these

gasket surfaces.

Secure these pieces with the

4

screws with

lock washers.

PIN

Figure

30

10. Replace the fuel diaphragm pump parts by

installing the pump cover gasket against the

carburetor, the pump diaphragm against the

pump cover gasket, the pump cover against

the pump diaphragm and securing these

pieces with the

4

screws with lock washers.

See Fig. 31.

Loading...

Loading...