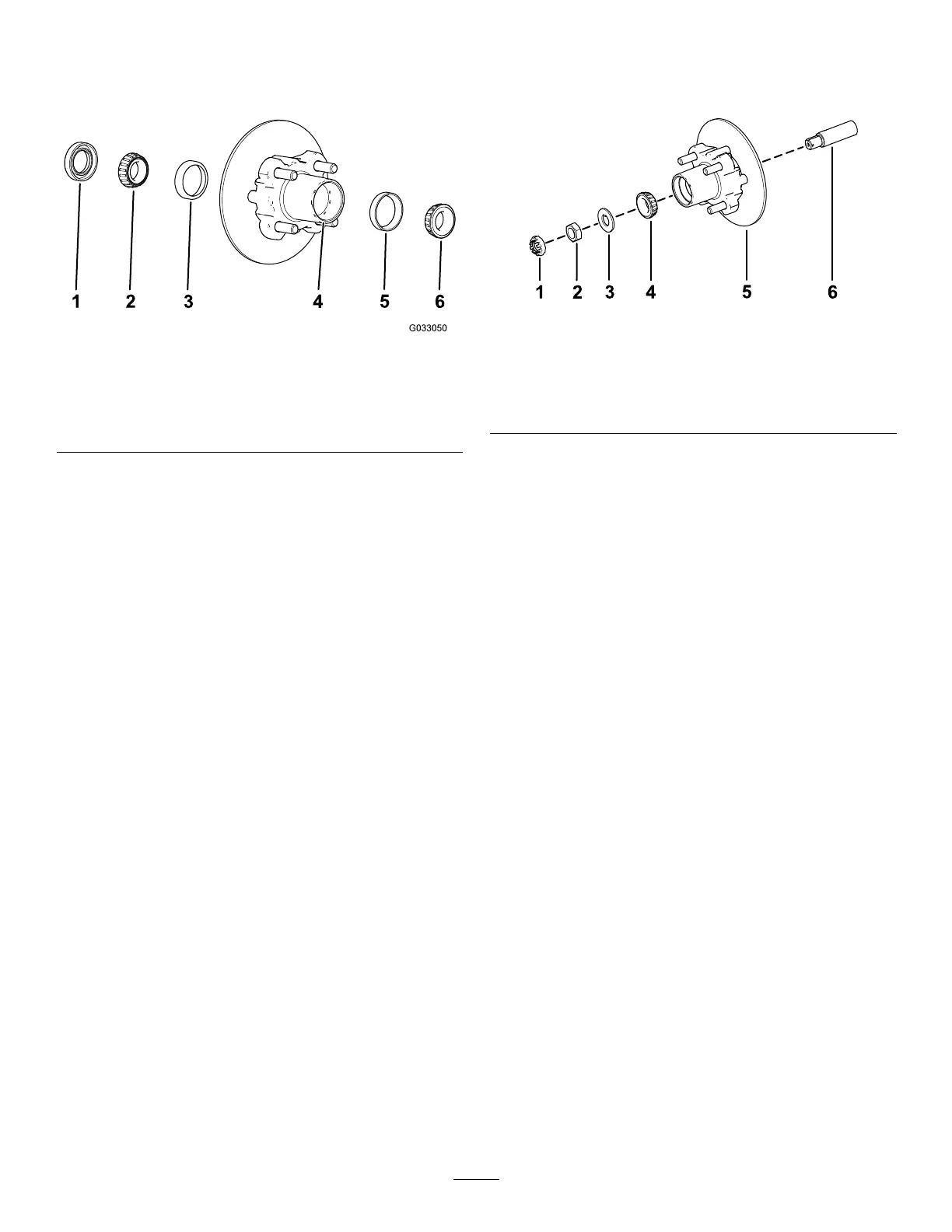

GreasingtheWheelBearings

1.Removetheoutboardbearingandbearingrace

fromthehub(Figure37).

g033050

Figure37

1.Seal4.Bearingcavity(hub)

2.Inboardbearing

5.Outboard-bearingrace

3.Inboard-bearingrace

6.Outboardbearing

2.Removetheseal,inboardbearingfromthehub

(Figure37).

3.Wipecleanthesealandcheckforwearand

damage.

Note:Donotusecleaningsolventtocleanthe

seal.Replacethesealifitiswornordamaged.

4.Cleanthebearingsandraces,andcheckthese

partsforwearanddamage.

Note:Replaceallwornordamagedparts.

Ensurethatthebearingsandracesareclean

anddry.

5.Cleanthecavityofthehubofallgrease,dirt,

anddebris(Figure37).

6.Packthebearingswiththespeciedgrease.

7.Fillthecavityofhub50to80%fullofthe

speciedgrease(Figure37).

8.Assembletheinboardbearingontotheraceat

theinboardsideofthehubandinstalltheseal

(Figure37).

9.Repeatsteps1through8tothebearingsforthe

otherhub.

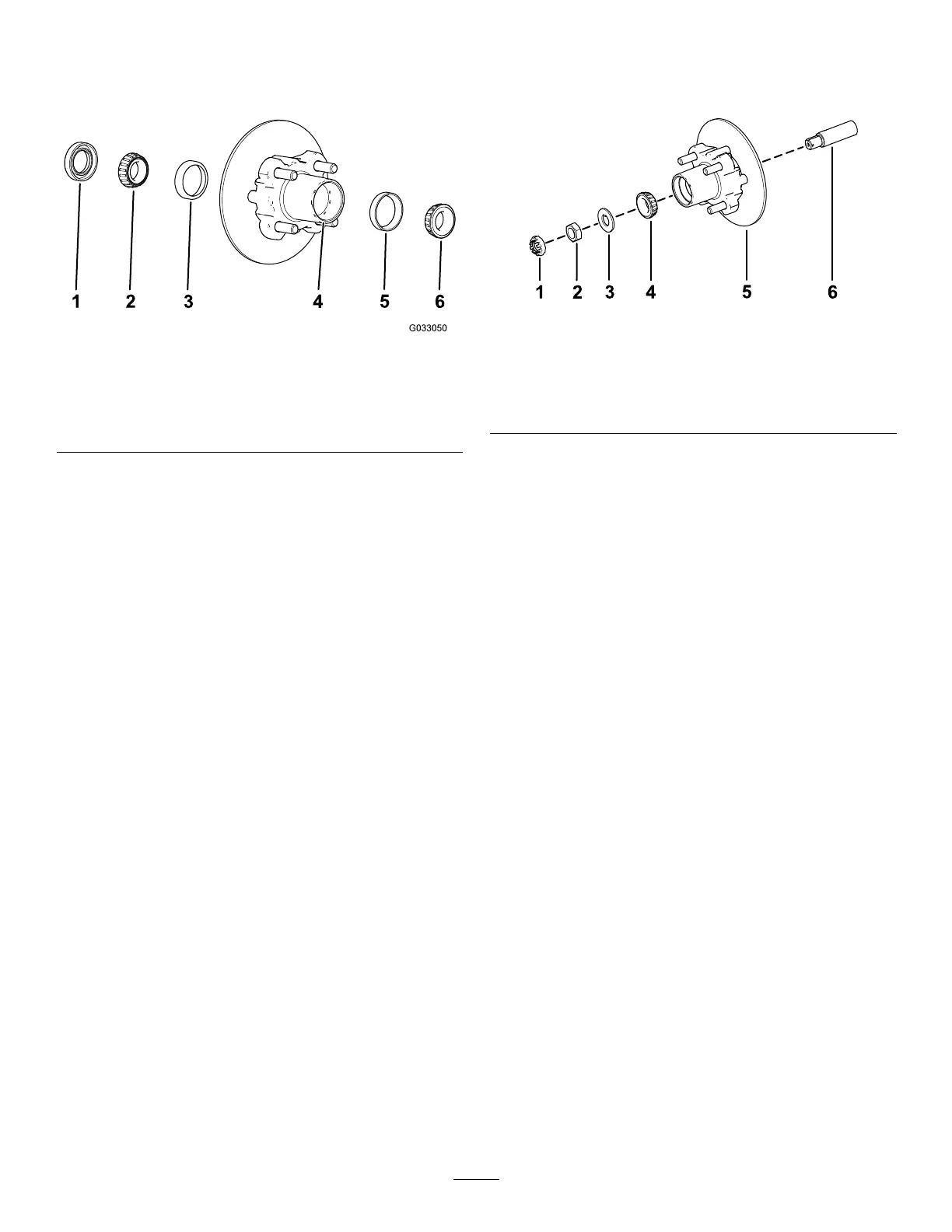

InstallingtheHubandRotor

1.Applyalightcoatofthespeciedgreasetothe

spindle(Figure38).

g192344

Figure38

1.Nutretainer

4.Outerbearing

2.Spindlenut

5.Hub,rotor,innerbearing,

race,andseal

3.Tabwasher

6.Spindle

2.Assemblethehubandrotorontothespindle

withtherotorinboard(Figure38).

3.Assembletheoutboardbearingontothespindle

andseatthebearingtotheoutboardrace

(Figure38).

4.Assemblethetabwasherontothespindle

(Figure38).

5.Threadthespindlenutontothespindleand

tightenthenutto15N∙m(11ft-lb),whilerotating

thehubtoseatthebearing(Figure38).

6.Loosenthespindlenutuntilthehubrotates

freely.

7.Torquethespindlenutto170to225N∙cm(15

to20in-lb).

8.Installtheretaineroverthenutandcheckthe

alignmentoftheslotintheretainerandthehole

inthespindleforthecotterpin(Figure39).

Note:Iftheslotintheretainerandtheholein

thespindlearenotaligned,tightenthespindle

nuttoaligntheslotandholetoamaximum

torqueof226N∙cm(20in-lb)onthenut.

34

Loading...

Loading...