P9 ASD Installation and Operation Manual 73

Virtual Linear Pump Setup

Toshiba International Corporation’s Virtual Linear Pump algorithm allows for direct and precise

control of pressure, flow rate, or level. This is achieved without the concerns, instabilities, or

complexities that are traditionally associated with pumping system control.

This section provides useful setup and operational information for the Virtual Linear Pump system.

The system is initially configured using the (Program Virtual Linear Pump ) Virtual Linear

Pump Setup Wizard. Once the Wizard is started, it must be completed for normal Virtual Linear

Pump operations to function.

However, the parameters addressed while using the Wizard or the Virtual Linear Pump Settings menu

selection are also accessible via their associated direct access numbers for specific adjustments when

required.

If not using the Wizard to configure the settings of the Virtual Linear Pump algorithm, parameter

F911 must first be set to 255: Virtual Linear Pump to accept the new or changed Virtual Linear

Pump parameter settings. Upon completion of the parameter changes, set parameter F911 to 1 or 2 to

use the changed (new) settings for normal Virtual Linear Pump operations (Zero may be selected at

F911 to save the changes to be used later).

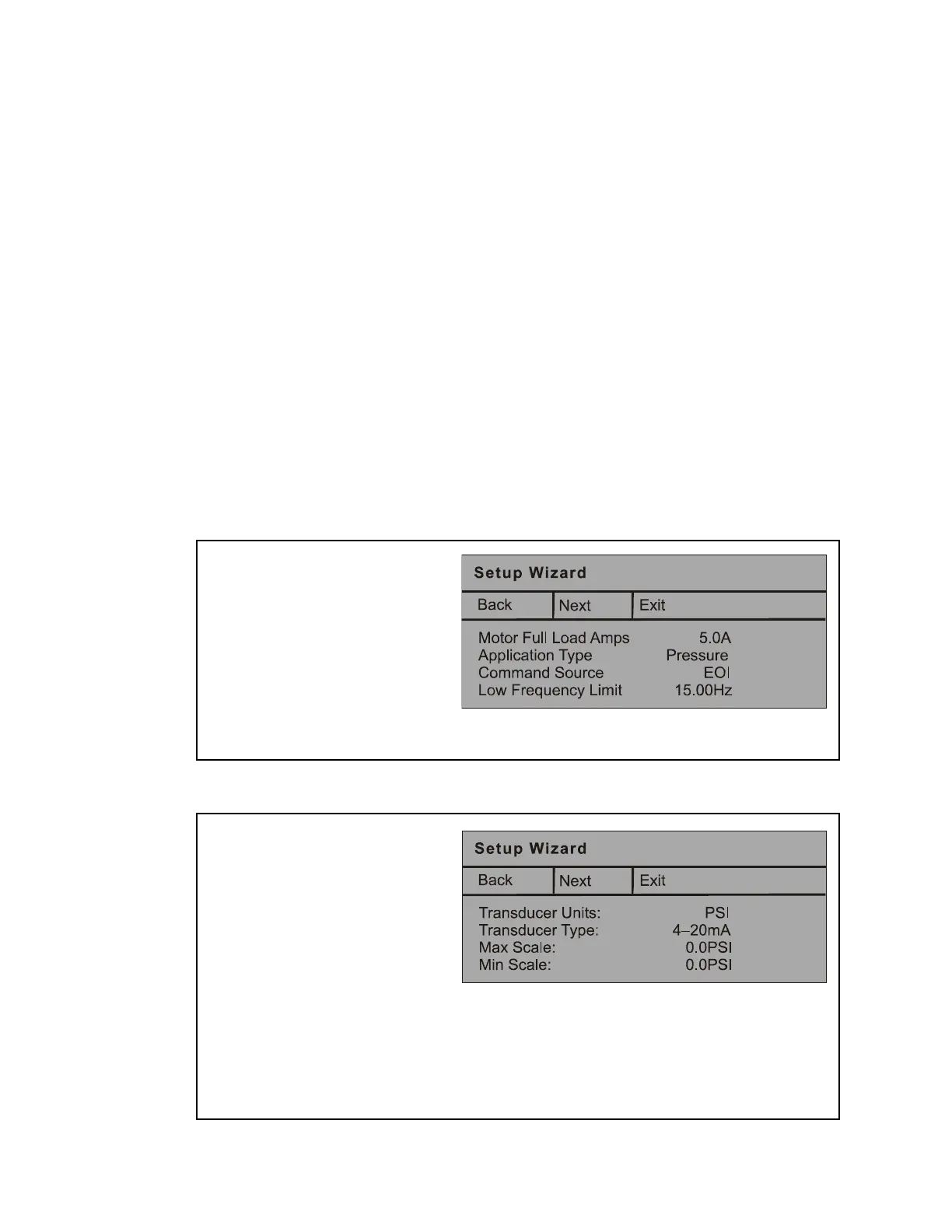

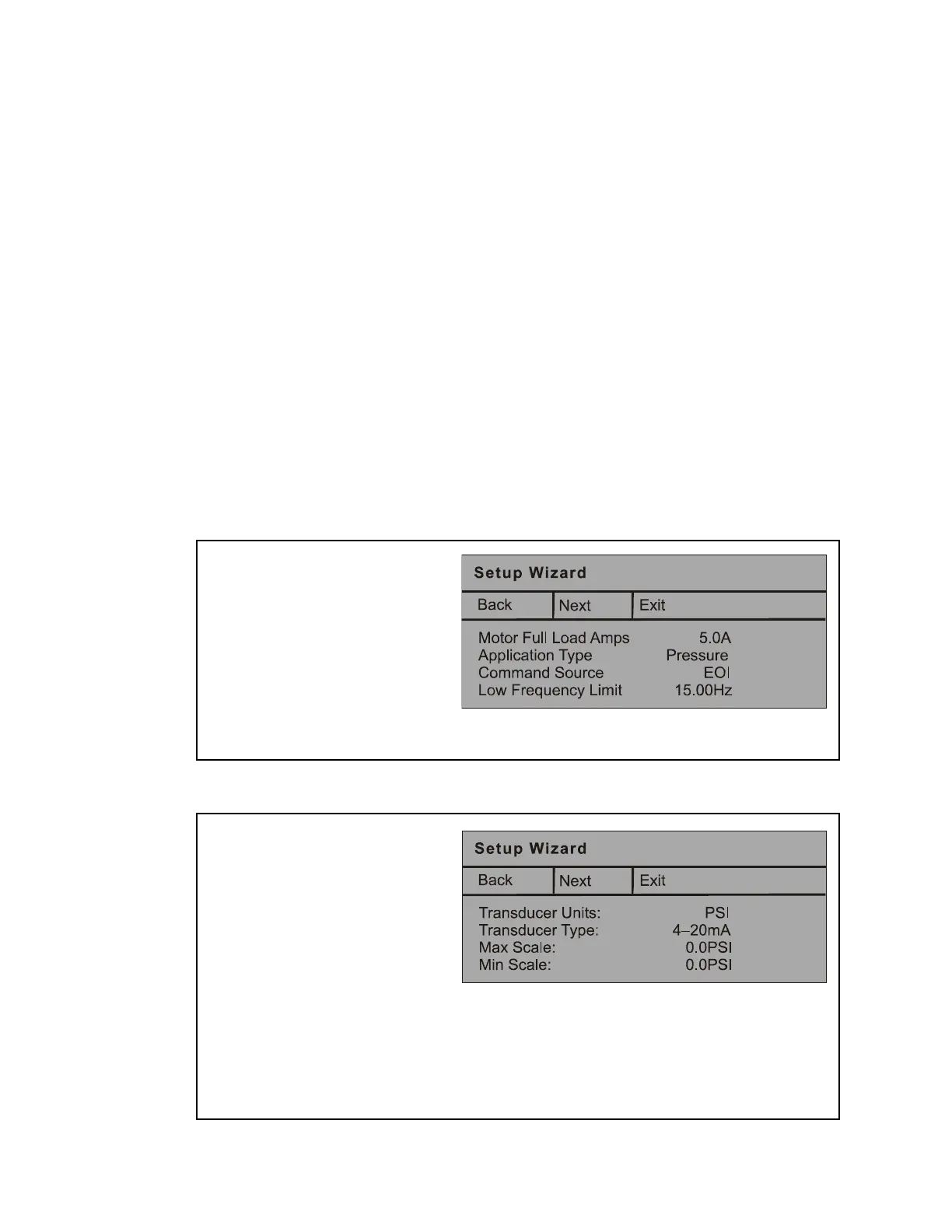

The setup procedure and the Wizard setup screens are shown below.

Figure 29. Input the Electrical Specifications of the Motor.

Figure 30. Input the Specifications of the Transducer.

1.Enter the FLA from the

nameplate of the motor.

2.Select Pressure or Level.

3.Select the command source:

EOI or V/I analog input.

4.Set the Low Frequency

Limit. 15 Hz fits most

applications.

5.Click Next to continue.

6.Set the unit of measure for

the transducer: pressure,

flow rate, or level (i.e., PSI,

GPM, Inches of Water

Column, Feet of Water

Column, or Cubic Feet per

Minute).

7.Select the transducer output

range and signal type:

Current or Voltage.

8.Set the full-scale reading of

the transducer.

9.Click Next to continue.

Loading...

Loading...