54

RT-SVX34V-EN

Table 26. 40 - 50 Ton horizontal economizer (O/A) damper static pressure setup (continued)

System

Design CFM

Return Air Duct Static + Return Air Damper Static (Inches of Water)

0.2 0.4 0.6 0.8 1 1.2 1.4

Drive Rod Position

21000 A A A A A B D

21500 A A A A A B D

22000 A A A A A A B

Models with Ultra-Low Leak Economizers

The installer can adjust the stroke of the direct drive

actuator on the O/A damper to compensate for various R/A

duct losses. Figure 43, p. 54 and Figure 44, p. 55 illustrate

the damper & actuator assembly and through list the

various O/A actuator limit positions based on the air flow

(CFM) and the return duct losses (static pressure) for

Downflow and Horizontal units. The actuator stroke limit

can be adjusted between 33% and 100% of full stroke. To

adjust the O/A damper for the correct pressure drop:

1. Measure the return duct static pressure.

2. Enter the calculated CFM from the previous section

“Verifying Proper Air Flow (CFM),” p. 42 to obtain the

return air damper pressure drop.

3. Add the measured return duct static pressure and the

return air damper pressure drop together to obtain the

Total Return Static Pressure. Apply this calculation and

the calculated CFM to the appropriate table. See

through .

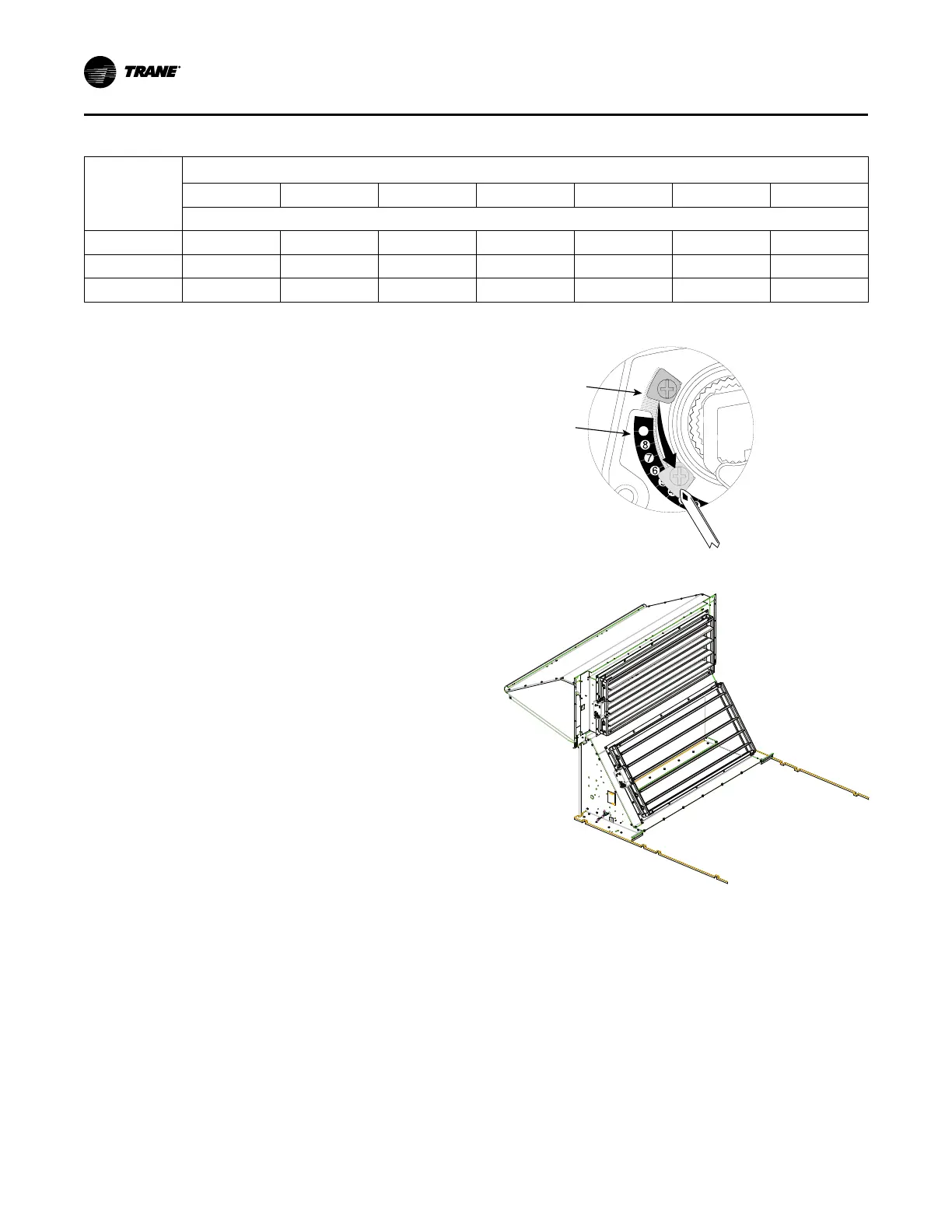

4. To set the actuator stroke limit:

a. Loosen the screw that secures the angle of rotation

limiter on the actuator adjacent to the damper drive

shaft clamp.

b. Move the limiter to the desired % open position and,

making sure the limiter teeth are engaged, retighten

the screw. (See Figure 42, p. 54).

5. After setting the end stop, the actuator needs to be

cycled through its auto-adapt feature to re-scale the

control range. With 24 VAC power applied to the

actuator, turn the control signal reversing switch

forward and back again two times. Within a few

seconds, the actuator will cycle itself to the new limiter

position and then back to zero. This process may take

up to 5 minutes. The actuator will then be set to

respond to the 2-10 VDC control signal to cycle within

the new range of rotation set by the limiter. Verify that

the control signal reversing switch is set back to its

original default position - Y = 0 - same direction as

spring return. (See Figure 45, p. 55).

Figure 42. Actuator stroke limit adjustment

9

Philips screwdriver

Angle of Rotation

Limiter

Scale Shows % of

Full Stroke

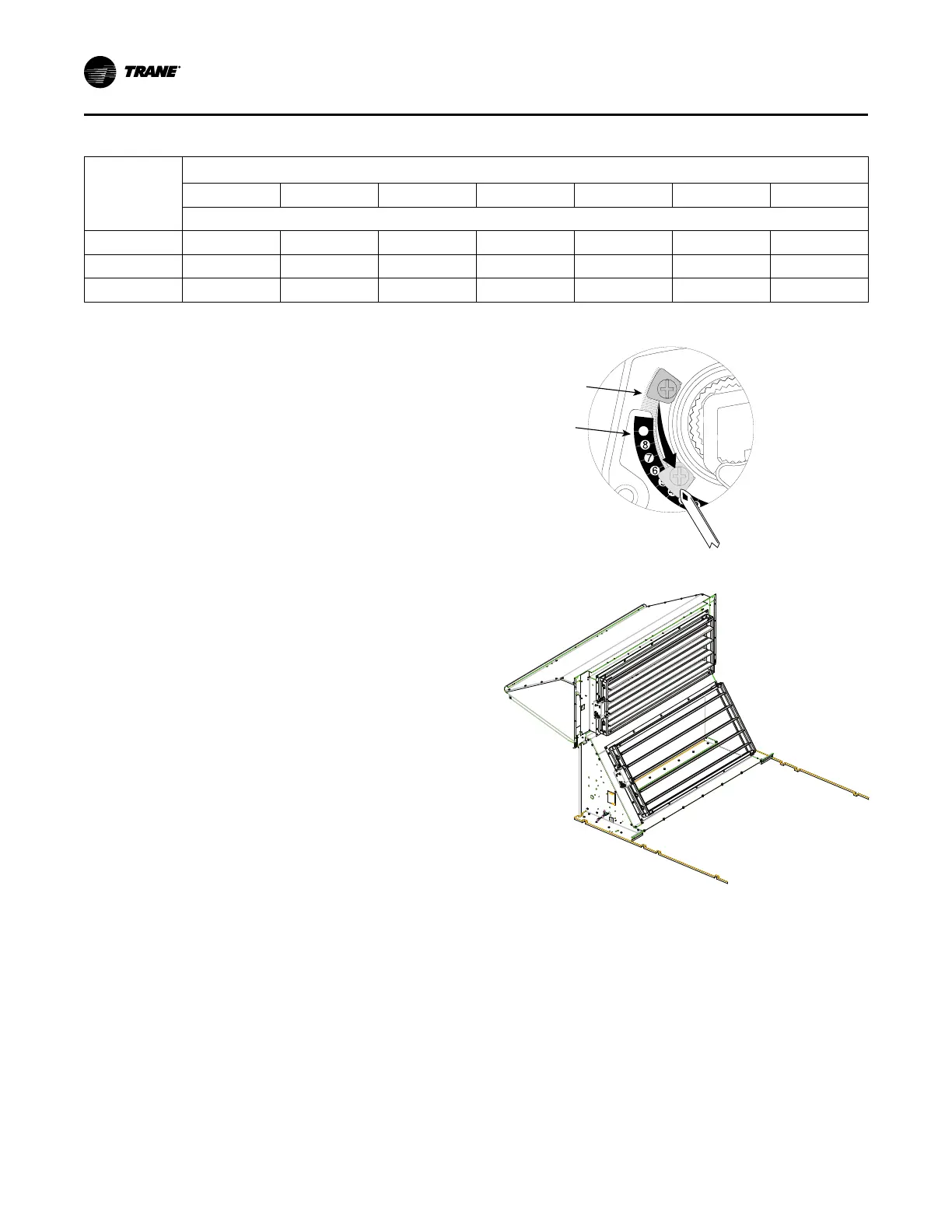

Figure 43. Actuator for OA damper - Downflow

Startup

Loading...

Loading...