Start-Up

CLCH-SVX009A-EN 53

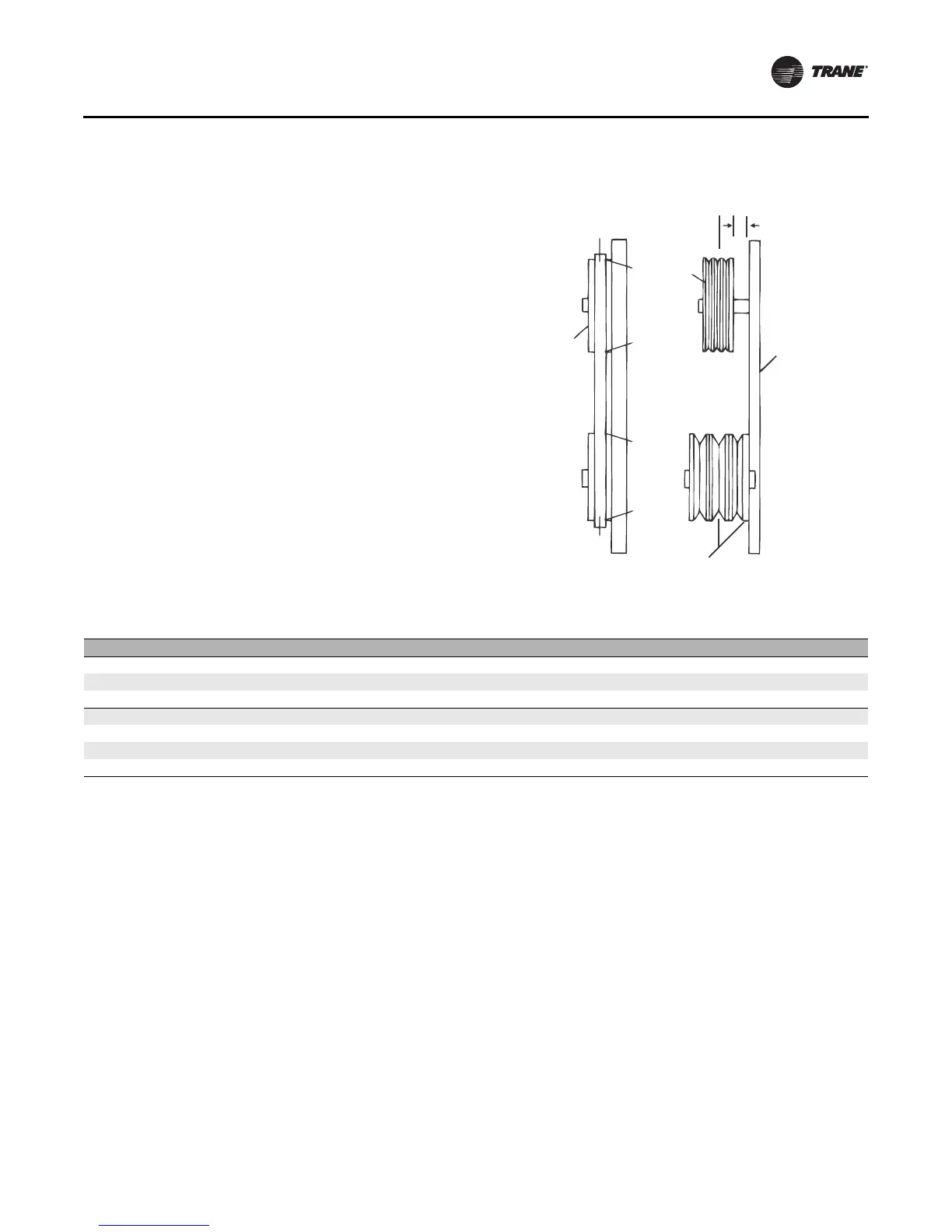

Align Fan and Motor Sheaves

Align the fan and motor sheaves using a straightedge. The

straightedge must be long enough to span the distance

between the outside edges of the sheaves. When the

sheaves are aligned, the straightedge will touch both

sheaves at points A through D (see Figure 46) to confirm

the shaft is parallel. For uneven width sheaves, place a

string in the center groove of both sheaves and pull tight.

Adjust the sheaves and tighten the sheave set screws to

the proper torque given in Tabl e 16 .

Check Multiple Belts

Tighten the belts slightly and rotate the drive several

times.

On multiple belt drives, ensure the force of deflection is

approximately the same on each belt by pushing each belt

in an equal distance at a point halfway from each sheave

(see Figure 46). If this force is not the same for each belt,

the motor and fan shaft are not parallel. Realign as

required. After realignment, tighten the belts again to the

standard belt tensioning specifications. If the force is still

not the same for all belts, the belts or sheaves are worn

and must be replaced.

External Insulating Requirements

The following areas should be specifically addressed, as

applicable:

• Supply and return water piping connections

• Supply and return refrigerant piping connections

• Condensate drain lines and connections

• Outdoor-air-intake duct connections

• Discharge duct connections

• Special requirements for low-temperature-air systems

Figure 46. Proper drive alignment

D

Fixed

Sheave

C

B

A

Adjustable

Sheave

Straight

Edge

Lines must

be parallel

Center line

must coincide

Fixed

Sheave

Table 16. Set screw torque settings (inches)

Screw Size Hex Key Square Head Hex Head Torque (in.-lb.) Torque (ft.-lb.)

1/4 1/8 3/8 7/16 66-90 5.5-7.5

5/16 5/32 1/2 1/2 126-164 10.5-13.7

3/8 3/16 9/16 9/16 228-300 19.0-25.0

7/15 7/32 5/8 5/8 348-450 29.0-37.5

1/2 1/4 3/4 3/4 504-650 42.0-54.2

5/8 5/16 15/16 15/16 1290-1390 107.0-116.0

#10 3/32 - - 28-40 2.3-3.3

Loading...

Loading...