Routine Maintenance

60 CLCH-SVX009A-EN

Fans

Inspecting and Cleaning Fans

Fan sections of air handlers should be inspected every six

months at a minimum or more frequently if operating

experience dictates. If evidence of microbial growth

(mold) is found, identify and remedy the cause

immediately. Refer to “Troubleshooting” on page 62 for

possible causes and solutions. To clean the fan section:

1. Disconnect all electrical power to the unit.

2. Wearing the appropriate personal protective

equipment, remove any contamination.

3. Vacuum the section with a vacuum device that uses

high-efficiency particulate arrestance (HEPA) filters

with a minimum efficiency of 99.97 percent at

0.3 micron particle size.

4. Thoroughly clean any contaminated area(s) with a

mild bleach and water solution or an EPA-approved

sanitizer specifically designed for HVAC use.

5. Immediately rinse the affected surfaces thoroughly

with fresh water and a fresh sponge to prevent

potential corrosion of metal surfaces.

6. Allow the unit to dry completely before putting it back

into service.

7. Be careful any contaminated material does not contact

other areas of the unit or building. Properly dispose of

all contaminated materials and cleaning solution.

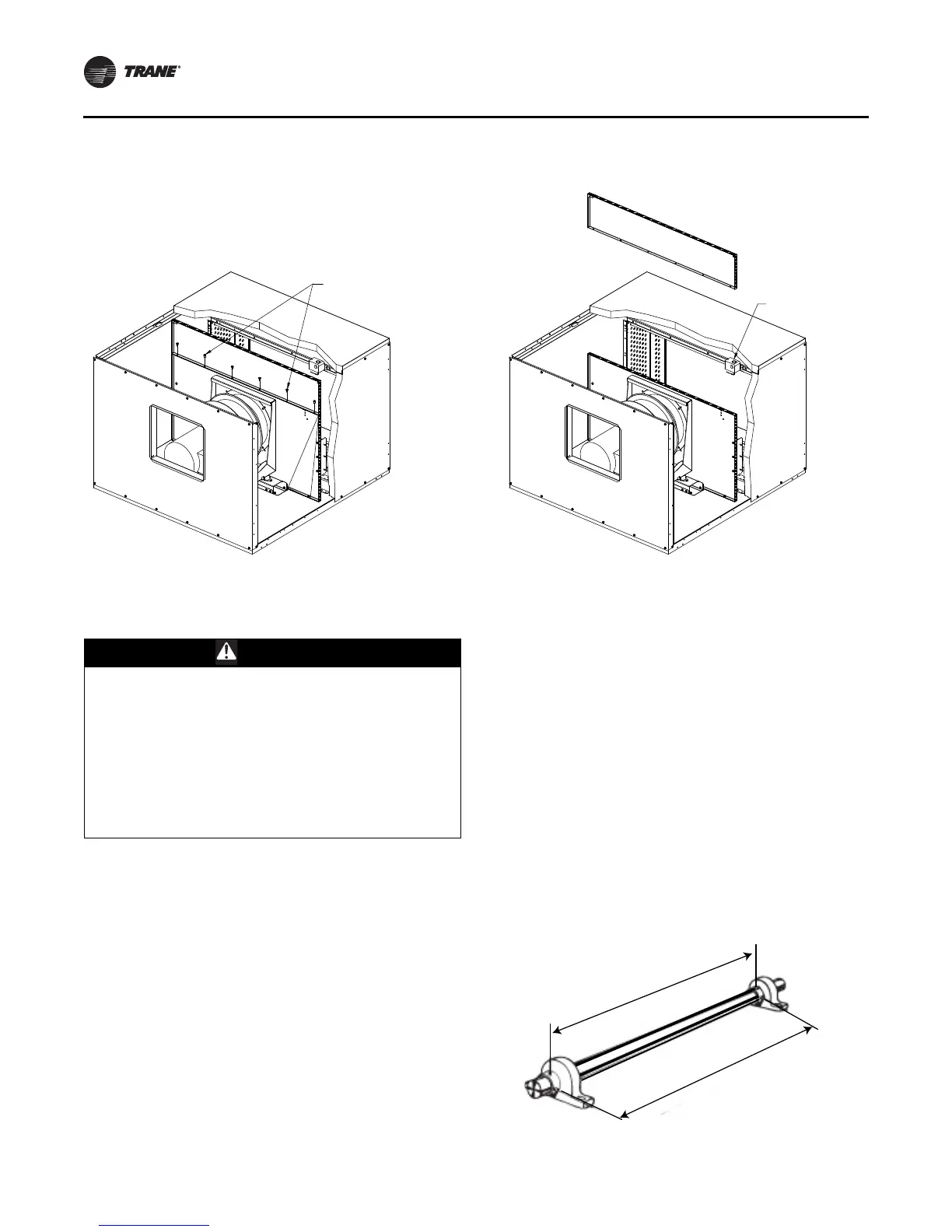

Bearing Set Screw Alignment

Align bearing set screws for belt-drive fans as illustrated in

Figure 53. See Tab le 16 for set screw torque

measurements.

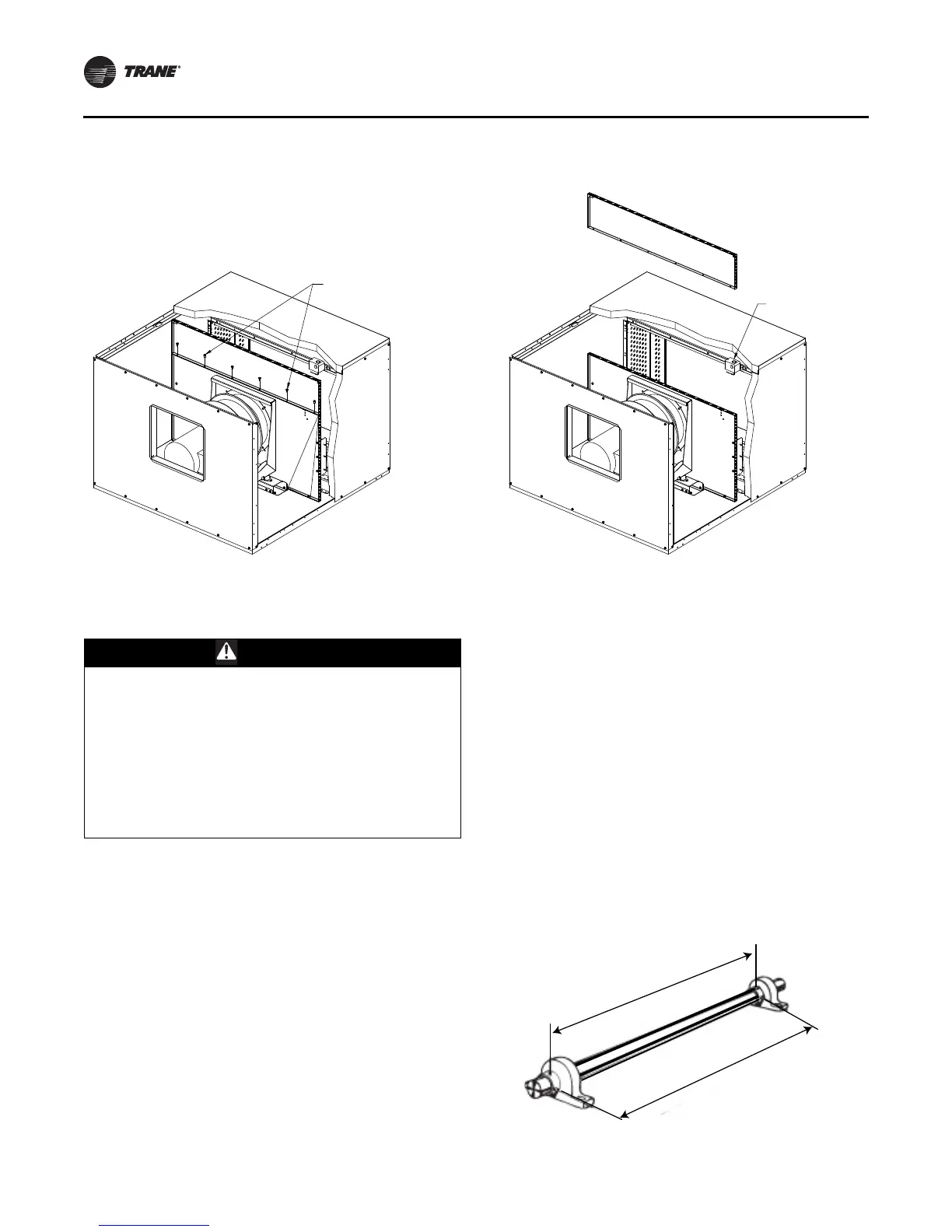

Figure 52. Resetting low limit switch for horizontal DDP fan units sizes 8 and 14-30

Removable

access panel

Low limit freeze stat

Panel removed

from unit

Screw: 10-16 x 0.750 self-driller

Remove all from perimeter of panel

WARNING

Rotating Components!

The following procedure involves working with rotating

components. Disconnect all electric power, including

remote disconnects before servicing. Follow proper

lockout/ tagout procedures to ensure the power can

not be inadvertently energized. Secure rotor to ensure

rotor cannot freewheel. Failure to secure rotor or

disconnect power before servicing could result in

rotating components cutting and slashing technician

which could result in death or serious injury.

Figure 53. Alignment

Align set screws

Align set screws

Loading...

Loading...