Installation

30 RT-SVX21N-EN

120F,YHC120E andYHC072F-102F units secure the tab

on left side to the indoor coil block off with one of the

screws removed in step 2 and secure the right side of

the bracket with one of the screws removed from the

access panel. Refer to Figure 35, p. 29.

5. Using the remaining 2 screws removed in step 2,

secure the bottom bracket. Refer to Figure 34, p. 29.

Note: Larger diameter holes on bottom bracket line up

with the dimples on the rear panel.The smaller

diameter holes line up with the screw holes in the

rear panel.

Main Electrical Power

Requirements

Verify that the power supply complies with the unit

nameplate specifications.

• Inspect all control panel components; tighten any

loose connections.

• Connect properly sized and protected power supply

wiring to a field-supplied/installed disconnect switch

and to the main power terminal block (HTB1) in the unit

control panel.

• Install proper grounding wires to an earth ground.

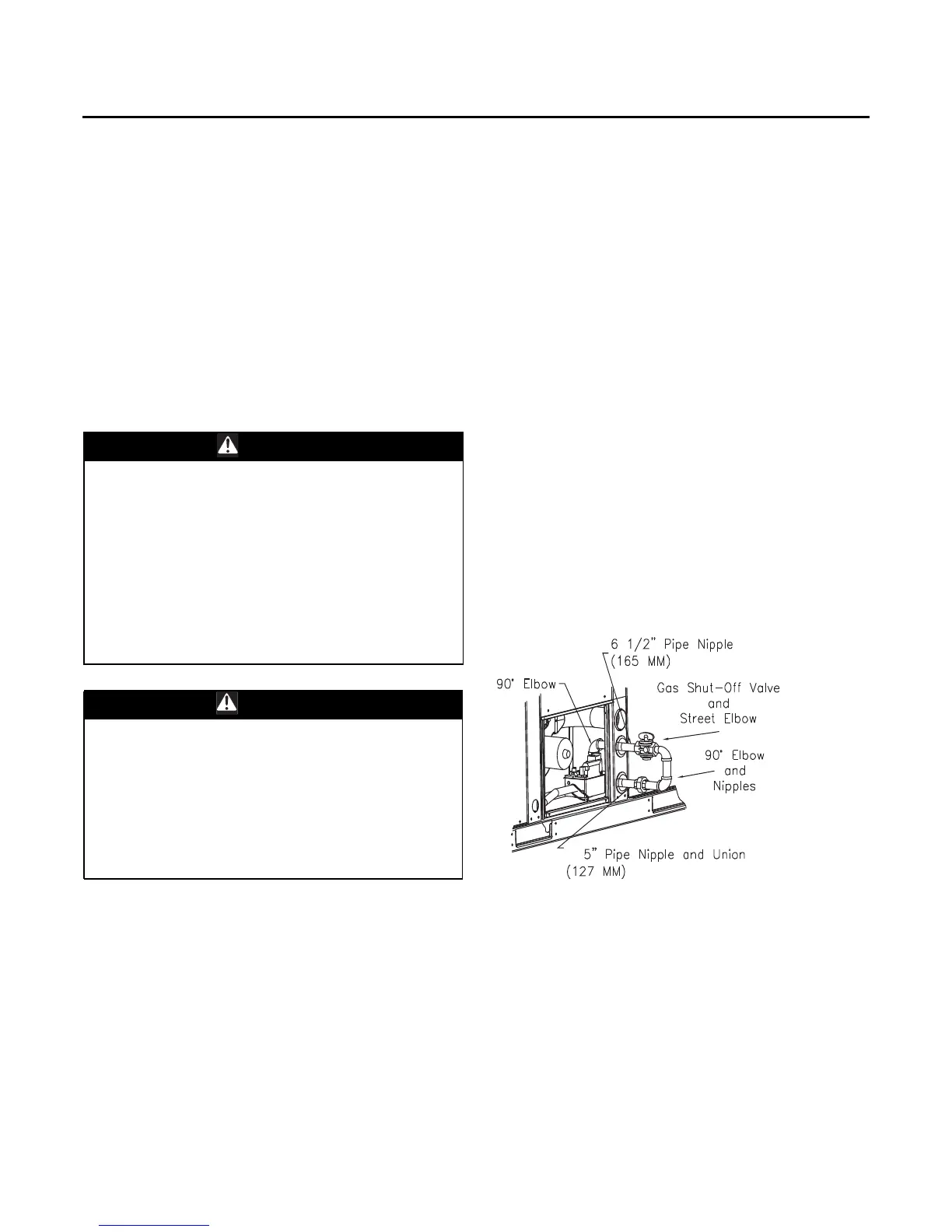

Through-the-Base Gas

Installation

The gas supply line must extend 4⅝” above the base pan.

The “Through-the-Base Gas” kit is located in the Heat

Vestibule compartment.To gain access to the kit, remove

the Heat Compartment access panel.

1. Remove the pipe assembly strapped to the manifold.

Unscrew 90° elbow from 6½” nipple and slide rubber

grommet off of nipple.

2. Remove the plastic plug from the hole in the center

post and insert the grommet removed from

6½” pipe nipple.

3. Using pipe sealant, attach the 90° elbow to the gas

supply line.

4. Disconnect the 5" pipe nipple and union from the

“Through-the-Base Gas” kit assembly.

5. Using pipe sealant, attach the 6½” nipple and gas

shutoff assembly to the 90° elbow on the gas supply

line.

6. Using pipe sealant, attach the 5" pipe nipple and union

to the street el attached to the gas valve.

7. Connect 5" pipe nipple and union to 6½” nipple and

gas shutoff assembly.

Requirements for Gas Heat

Note: The unit gas train and OptionalThrough-the-Base

Gas Shut-OffValve are rated at 1/2 PSIG maximum.

A pressure reducing regulator is recommended to

prevent this maximum from being exceeded.

These components must be isolated during field

gas piping test that exceed 1/2 PSIG. It is

recommended that the field piping be capped prior

to the unit gas train or OptionalThrough-the-Base

Gas Shut-Off Valve if present.

• Gas supply line properly sized and connected to the

unit gas train.

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. Verify with an appropriate

voltmeter that all capacitors have discharged. Failure to

disconnect power and discharge capacitors before

servicing could result in death or serious injury.

For additional information regarding the safe discharge

of capacitors, see PROD-SVB06A-EN

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards.To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Figure 36. Typical through-the-base gas installation

Loading...

Loading...