page -38

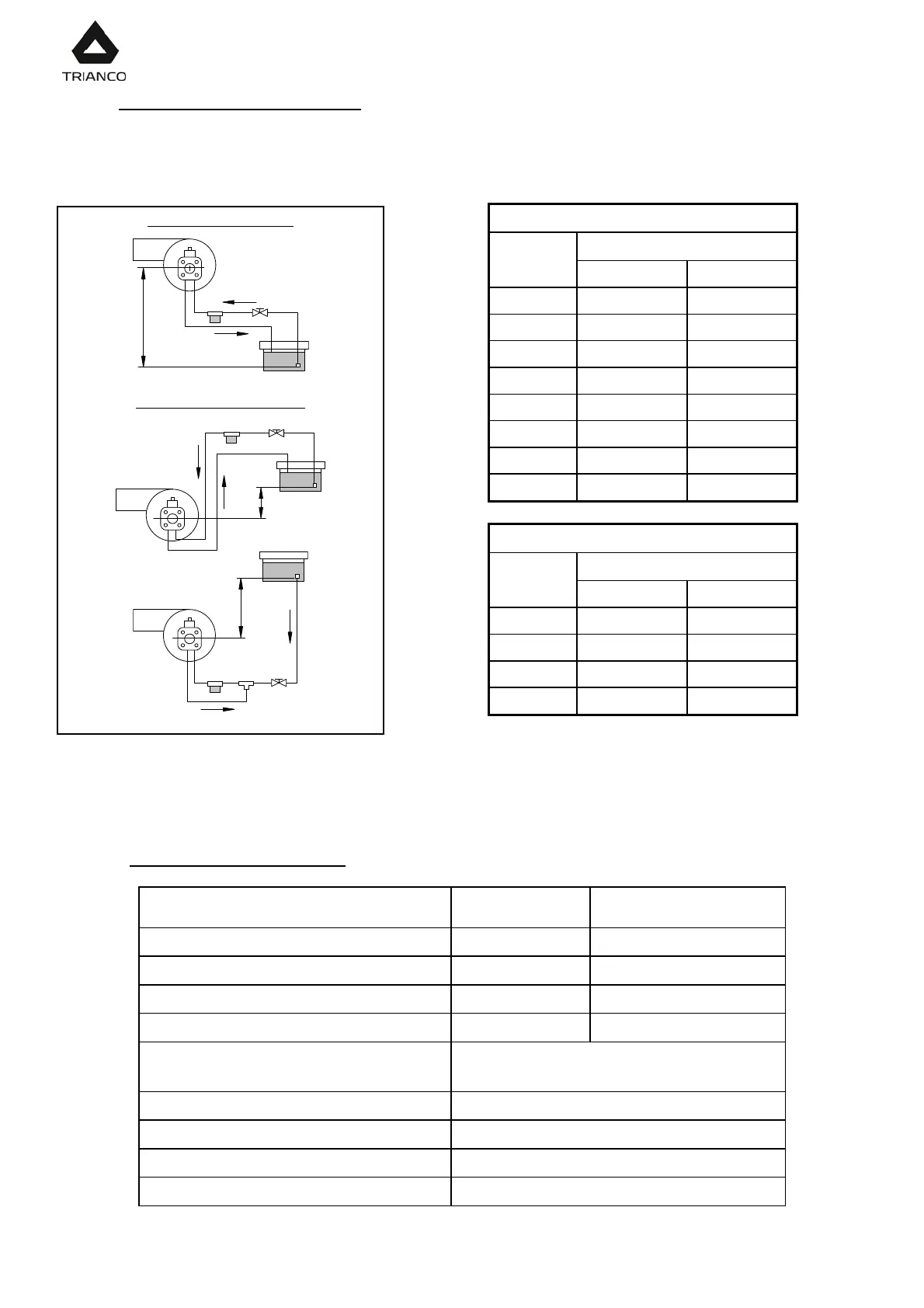

24.9.- Oil supply piping diagrams

The diagrams and tables below correspond to installations without reductions and with a

perfect hydraulic seal. It is recommended to use copper pipes. A pressure drop of 0.4 bar (30

cmHg) must not be exceeded.

Intake installation

H Pipe length

(m) int. 8 mm. int. 10 mm.

0.0 25 60

0.5 21 50

1.0 18 44

1.5 15 38

2.0 12 26

2.5 10 26

3.0 8 20

3.5 6 16

Charging installation

H Pipe length

(m) int. 8 mm. int. 10 mm.

0.5 10 20

1,0 20 40

1.5 40 80

2.0 60 100

WARNING: Check periodically the flexible pipes conditions. Using kerosene, they have to be

replaced at least every 2 years.

24.10.- Technical specifications

MODEL D-3 D-4

Minimum consumption Kg/h

1.5 2.3

Maximum consumption Kg/h

3 4.65

Minimum power kW

17.7 27.2

Maximum power kW

35.5 55.2

Fuel

Gas oil 35 Sec max. Viscosity 6 mm

2

/s at

20ºC Kerosene 28 Sec

Motor power at 2800 r.p.m. W

90-110

Adjustment type

On/Off

Electric current

220 V - 50 Hz

Weight Kg

12.5

Intake installation

H

Charging installation

H

H

Loading...

Loading...