10

Dual control built-in thermostatic mixer shower

BUILT-IN FITTING

The following are typical thicknesses and are

given as a guide only:

Tile 6 − 10mm

Adhesive 2 − 3mm

Plasterboard 9.5 − 12.5mm

Plaster nish 2 − 3mm

Maximum tile thickness to be 10mm.

When installing into a stud partition or other

hollow wall structure, the installer may wish to

consider building rear supports or other options

for tting the mounting plate. Such options are

beyond the scope of this guide.

Use the cover plate or tiling shroud (if supplied)

as a template when cutting the opening for

installing the shower into a solid wall, stud

partition or hollow wall structure.

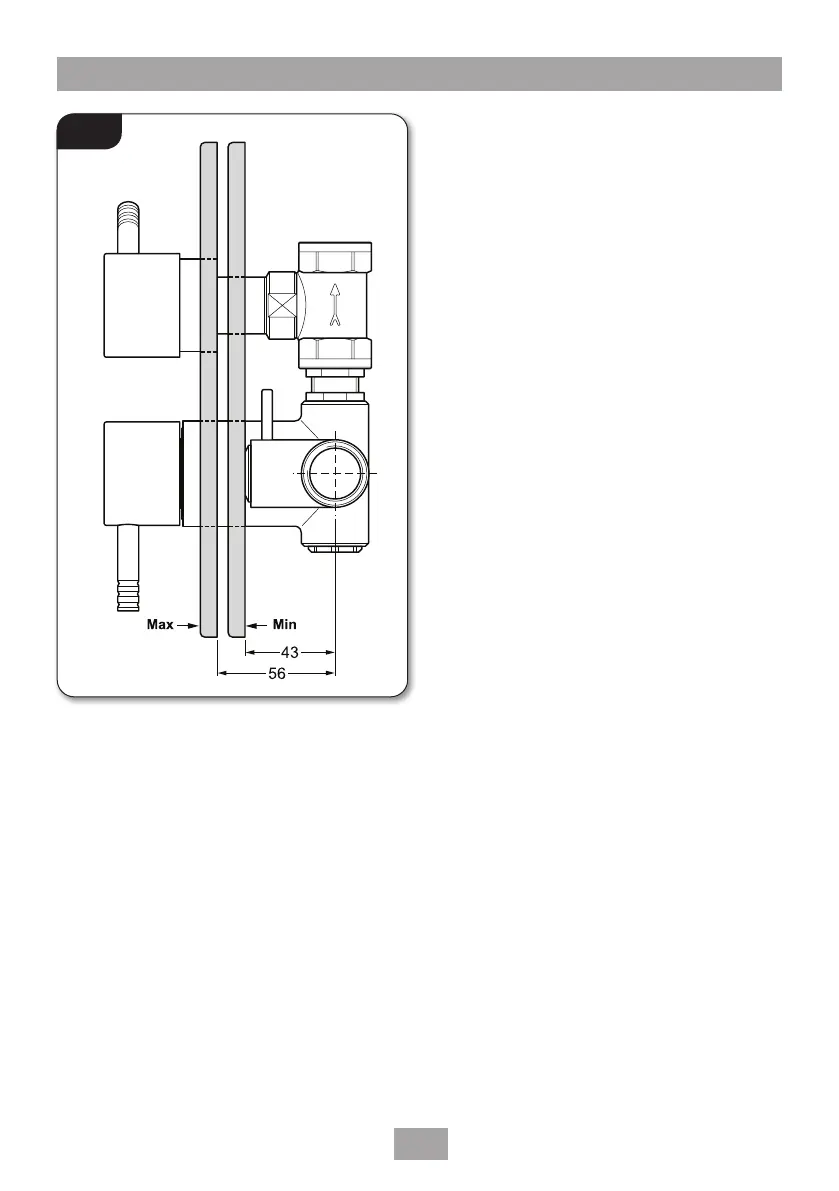

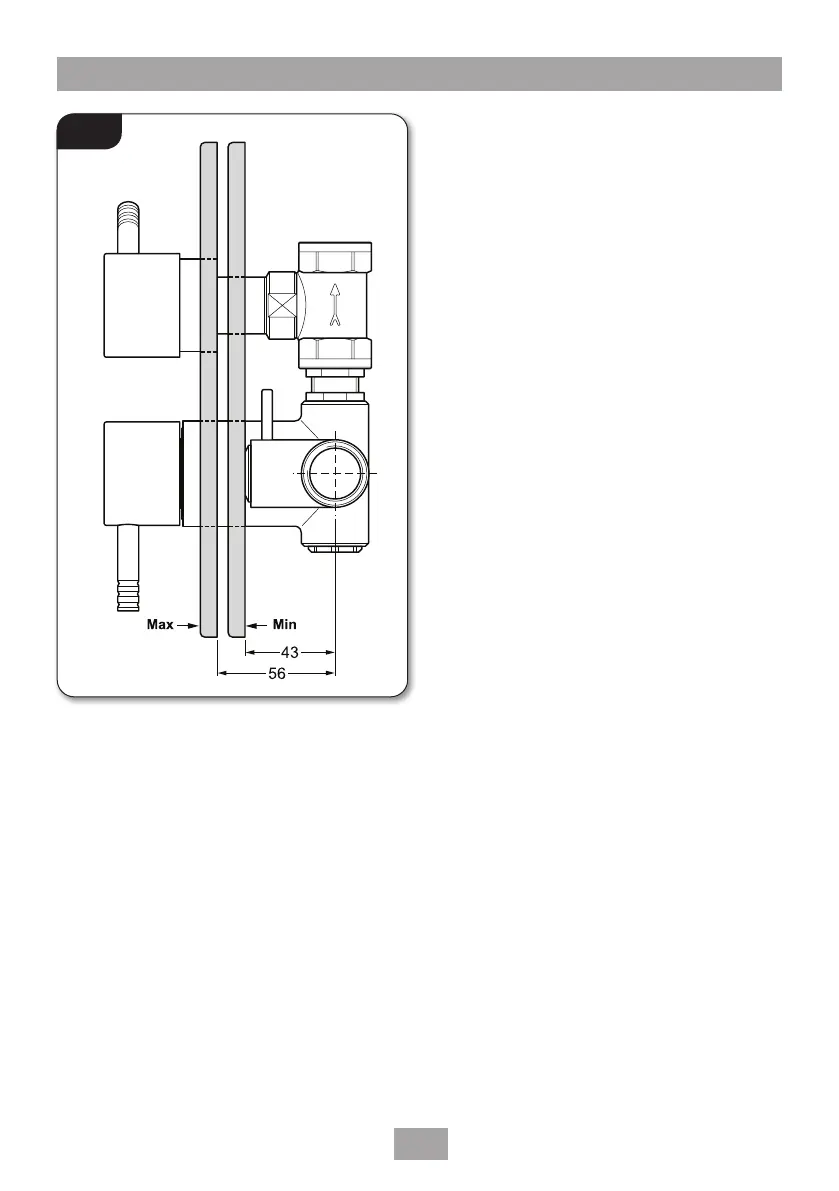

The building-in depth for the mounting plate

from the plaster nish is given in g.9 but this is

dependent upon tile and adhesive thicknesses.

The inlet elbows allow for either rising, falling or

rear entry hot and cold water supplies.

NOTE: To ease future requirements for

cleaning and maintenance of the unit, it is

advisable to route both the incoming and

outgoing pipework from the same direction.

Access to the integral strainers will also be

improved with this layout.

Installation in a Solid Wall

Decide on the shower position and determine

whether the hot and cold water supplies will

enter the shower from top (falling) or bottom

(rising) or rear.

As a guide for the size of hole, it should be large

enough to accept the valve complete with the

inlet and outlet ttings and also allow access for

connection to the pipework.

Remove the plaster and brickwork to the required

depth and chase out any additional areas of the

wall to give access to the pipework to and from

the valve plus any outlet ttings. Note that the

valve body requires a deeper recess than the inlet

and outlet ttings.

Fig.9

Loading...

Loading...