12

Dual control built-in thermostatic mixer shower

FITTING THE SHOWER

Mark the position of two locating screws.

Drill and plug the holes. Use an appropriate

masonry drill, but if the wall is plasterboard or a

soft building block, use special wall plugs and a

suitable drill bit.

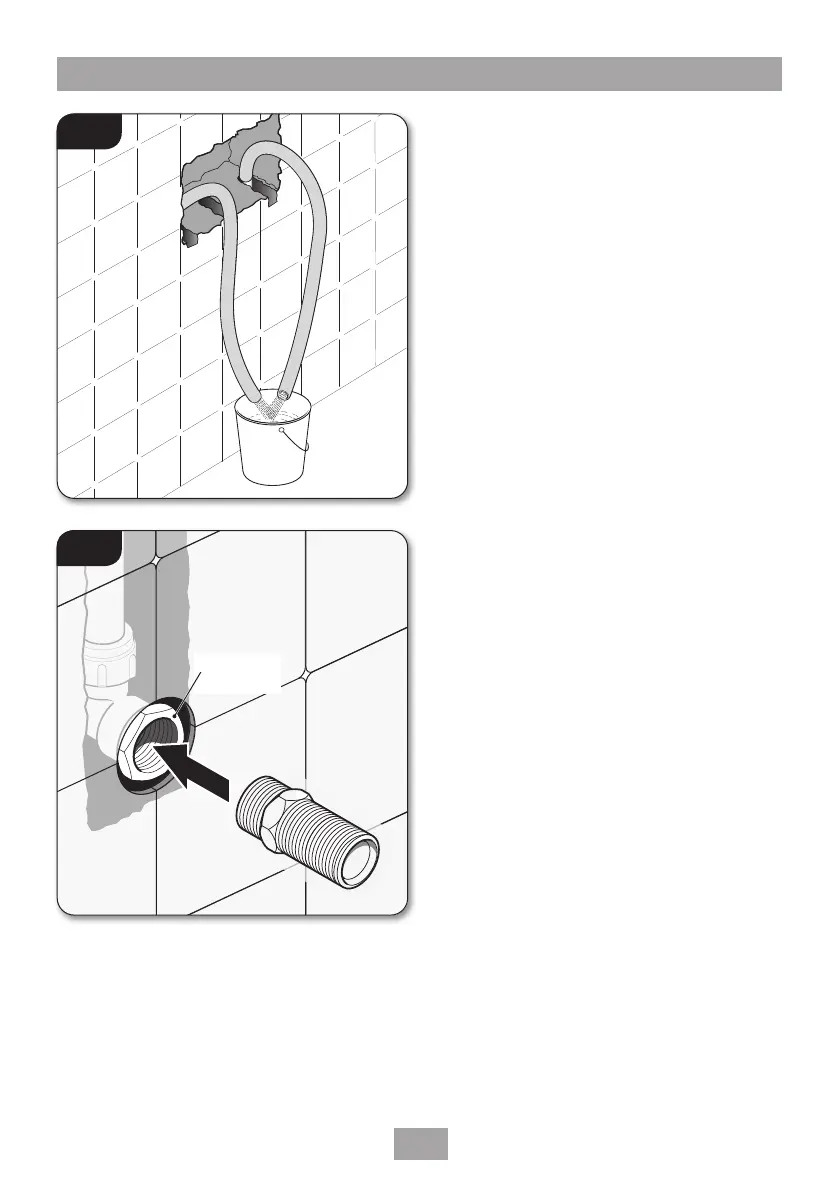

IMPORTANT: Make sure that all supply

pipework has been ushed through before

tting the mixer (g.11).

Connect the hot water supply to the inlet marked

HOT, ‘H’ or red/orange label and connect the cold

water supply to the inlet marked COLD, ‘C’ or

blue label.

Tighten all compression ttings.

Secure the mixer to the wall.

FITTING THE BULKHEAD PIPEWORK

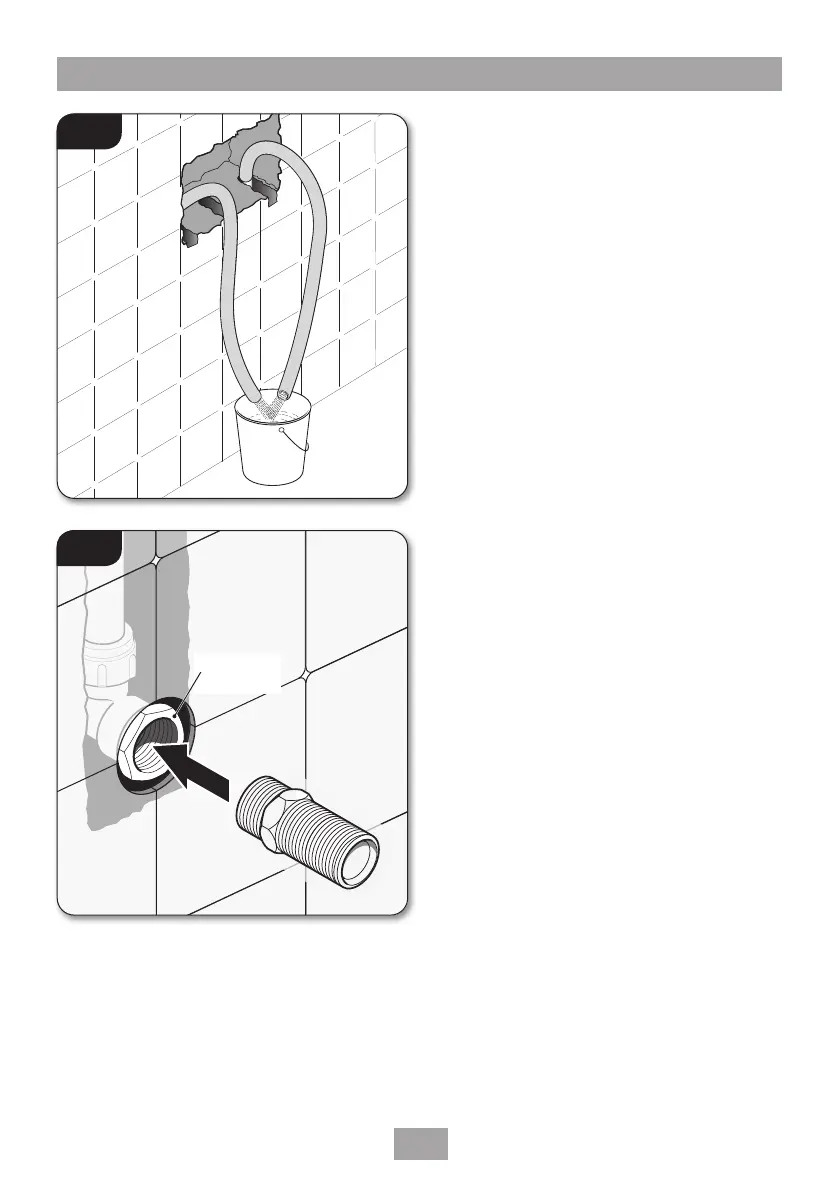

Complete the outlet pipework ending in a 15mm

x ½” BSP female thread elbow (g.12).

NOTE: This tting is not supplied as variations

in installations require the selection of a

suitable solder or compression tting.

Screw the supplied male-thread connector into

the female tting (g.13) using PTFE tape to

give a watertight joint.

NOTE: The male-thread connector supplied

has a shoulder. If tting into a ush wall, make

an additional 8mm allowance for this shoulder

at the nished surface. The connector can be

cut to size if required.

The threaded connector should protrude from the

nished wall surface between 8mm and 13mm.

LEAK TESTING

Direct the outlet of the shower to waste. Open

the isolating valves to the shower and check for

leaks. Remedy any leaks found.

Fig.11

8mm − 13mm

Finished surface

Fig.12

Appropriate

tting

Loading...

Loading...