13

Dual control built-in thermostatic mixer shower

MAKING GOOD

Make good the wall and complete the

tiling.

If the tiles are accurately cut, then the

coverplate will seal around the hole in the tiles,

and the valve unit will be able to be removed

from the wall without the need to break any

tiles.

Make sure the grout lines around the valve are

ush with the tiles in order to provide a smooth

sealing surface for the coverplate.

BULKHEAD ASSEMBLY

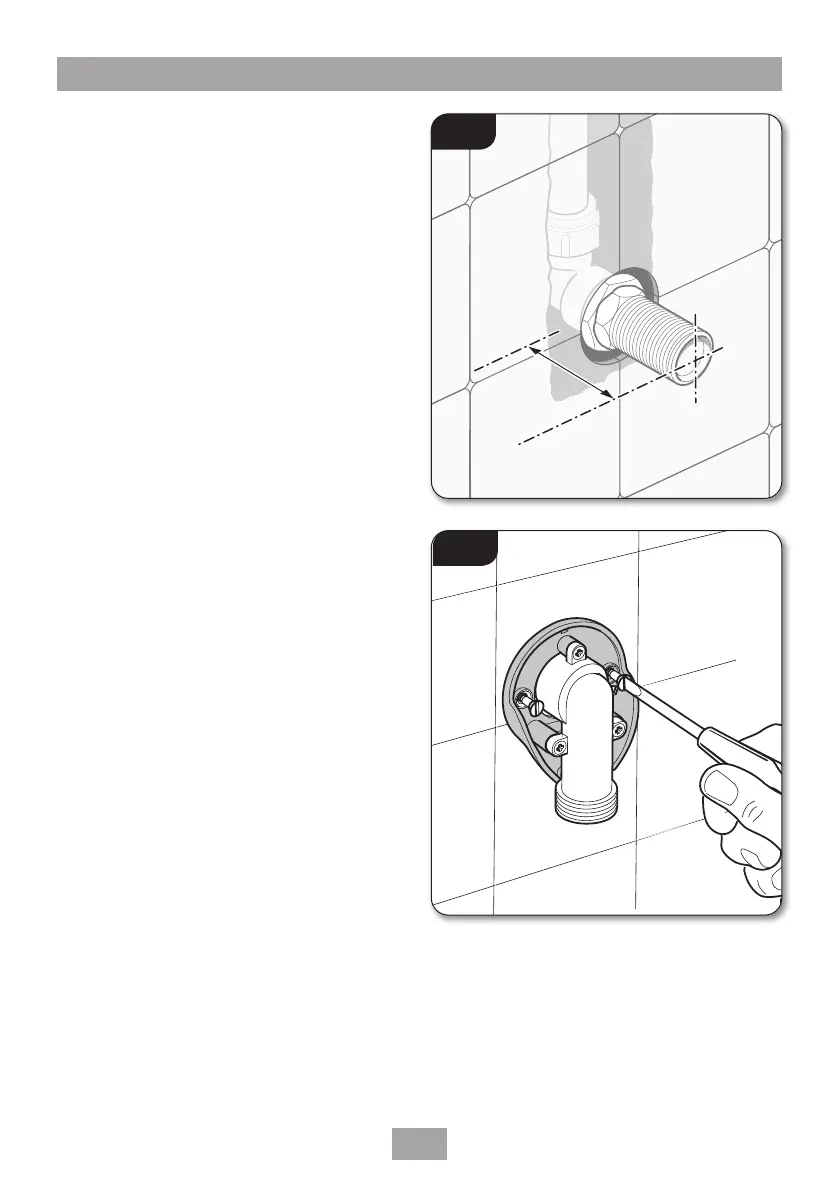

Screw the bulkhead elbow to the bulkhead body

with the three screws supplied.

Screw the completed assembly onto the

threaded connector temporarily to mark the

position of the two xing holes for securing the

bulkhead to the wall.

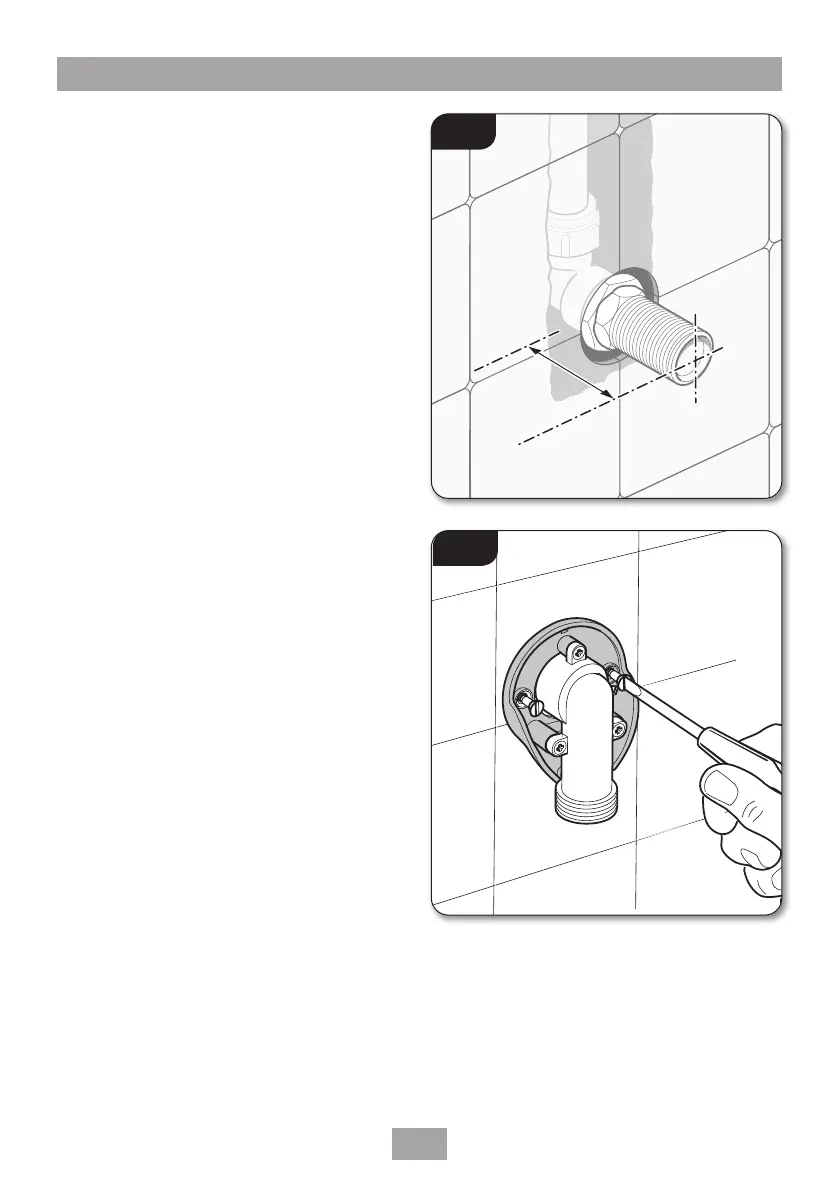

NOTE: If screw thread protrudes too far out

of the wall, it can be cut to the correct length

using a hacksaw.

Unscrew and remove the bulkhead assembly.

Check the location of the pipe in the wall before

drilling.

Drill and plug the wall. An appropriate drill bit

should be used. If the wall is brick, plasterboard or

a soft building block, appropriate wall plugs and

screws should be tted.

If tting to a hollow wall structure, it may be

preferable to secure the bulkhead by applying a

bead of silicon seal to the back of the bulkhead.

Apply PTFE tape to the threaded connector.

Screw the bulkhead assembly onto the threaded

connector until tight to the wall and the two

xing holes are aligned. Secure to the wall with

the two screws supplied (g.14).

Finish by clipping the cover onto the bulkhead,

making sure the protruding legs locate in the

bulkhead body.

Fig.14

Fig.13

8mm - 13mm

Loading...

Loading...