6

Dual control built-in thermostatic mixer shower

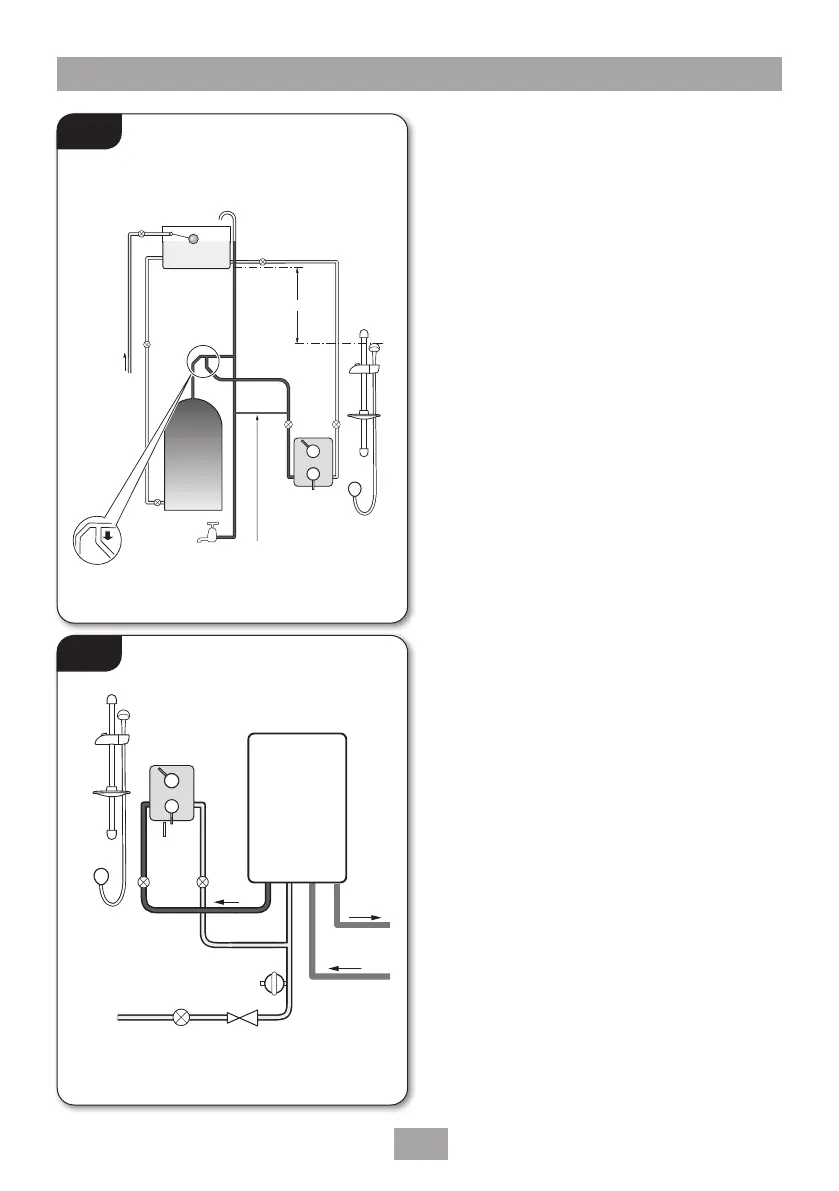

TYPICAL DOMESTIC INSTALLATIONS

Domestic Gravity Fed Systems (g.2)

The mixer shower MUST be fed from a cold

water cistern and hot water cylinder providing

nominally equal pressures. There must be a

minimum of one metre head of water. The

minimum head distance is measured from the

base of the cold water cistern to top of the

shower head.

If valves are gravity fed then supply pressure

should be veried to ensure conditions of use are

appropriate for the valve.

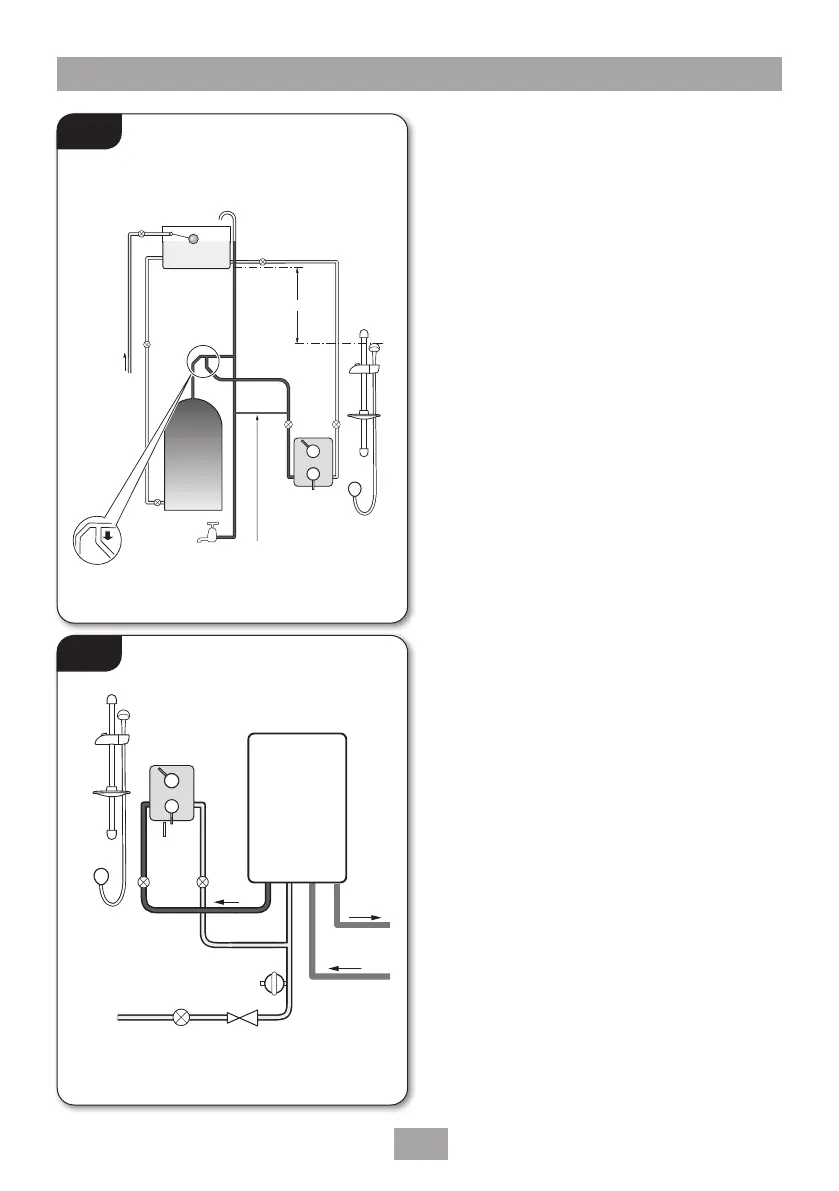

Instantaneous Gas-heated Systems,

e.g. combination boilers (g.3)

The mixer shower MUST be installed with a

multi-point gas water heater or combination

boiler of a fully modulating design i.e. to

maintain relatively stable hot water temperatures.

A drop tight pressure reducing valve MUST

be tted if the supply pressures exceed 5 bar

running.

An expansion vessel may be tted and regularly

maintained, to prevent the mixer shower

being damaged by excess pressures. This may

already be installed within the boiler (check with

manufacturer) and is in addition to the normally

larger central heating expansion vessel.

Hot water

cylinder

Kit

Cold supply

Hot supply

Alternative supply

(must be below

vent pipe tee)

Cold

water

mains

supply

Drain

valve

Gate

valve

Stop valve

Cold water

cistern

Minimum head

Other

draw-offs

Draw-off must point down

to avoid airlock issues

Service

valves

Mixer

*Fig.3

*Fig.2

CH flow

Cold

mains

supply

Hot water

CH return

Service

valves

Mixer

Stop

tap

Expansion

vessel

Pressure

reducing valve

Combination

boiler

Kit

*Diagrammatic view – not to scale.

For illustration purposes only.

*Diagrammatic view – not to scale.

For illustration purposes only.

Loading...

Loading...