REAR SUSPENSION

The swinging fork pivots on bronze bushes w

hi

ch shou

ld

be lubricated

with a high p

re

ssure grease gun at least every 1,000

mi

les (1,600Km)

until grease

is

seen to exude from the ends of the pivot

s.

There are two nipples, one beneath each bearing housing. If the mileage

intervals are not conven

ie

nt, it is better to grease more frequently rather

th

an to extend the interv

al.

The movement is controlled by

Gi

rl

in

g gas

pressurised mono tube damper units. The hydrau

li

c damping mecha

ni

sm

is completely sealed but the static loading of the spring is adjus

ta

ble.

There is a three

pOSition

castellated cam ring covered

by

a shroud

be

low

the chromium plated spring and a

"

C"

spanner is provided

in

the

to

olkit.

To increase the static loading of the spring, place the machine on the

stand so

th

at the

re

is least load

on

the spring and use

the

"C" spanner to

turn the

ca

m; both units must

be

on

th

e same notch

wh

i

ch

ever may be

chosen.

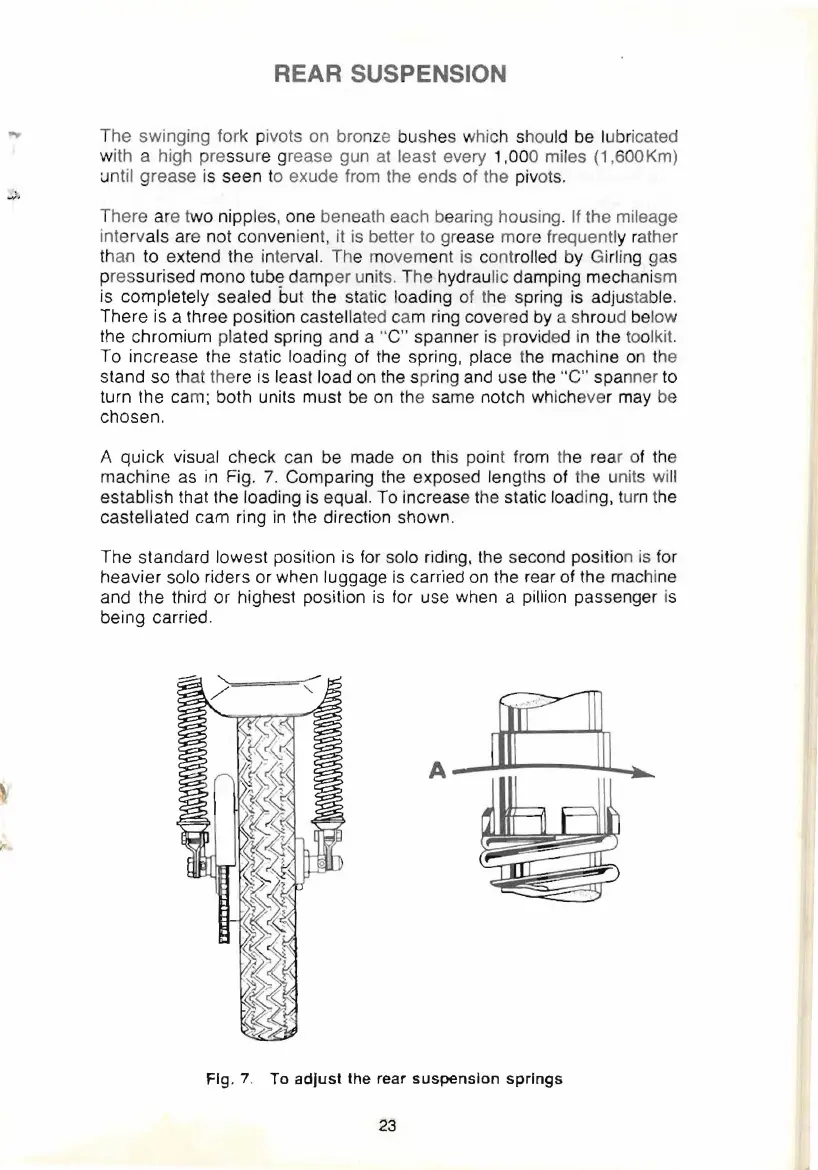

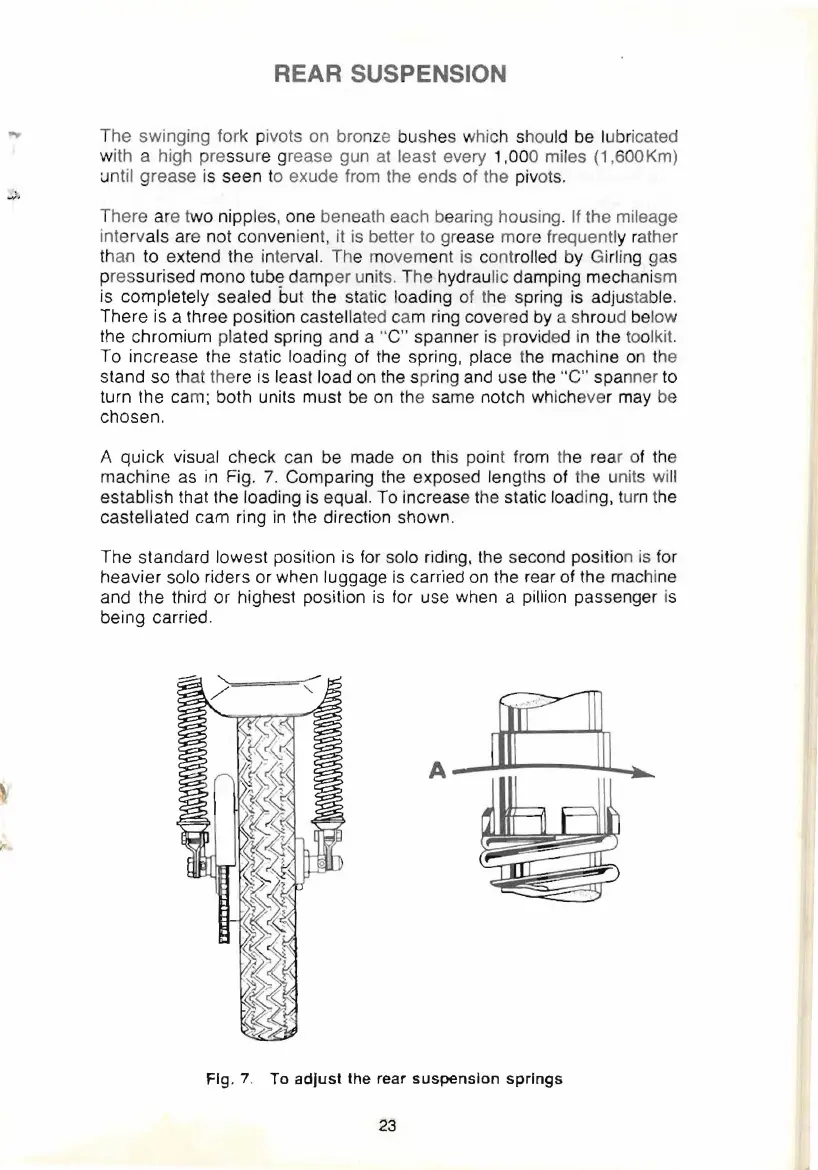

A quick visual check can be made on this paint from the rear of

th

e

machine as

in

Fig. 7. Comparing the exposed lengt

hs

of the units

wi

ll

establish that the loading is equal. To increase the static loading. tu

rn

the

castellated cam ring

in

the direction shown.

The standard lowest position is

for

solo riding, the second position

is

for

heavier solo riders or when luggage

is

carried on the rear of the machine

and the third or highest position

is

tor use when a pillion passenger is

being carried.

Fig. 7. To

adjust

the rear

suspension

springs

23

Loading...

Loading...