RUNNING ADJUSTMENTS

ADJUSTMENT

Setting the

Idle

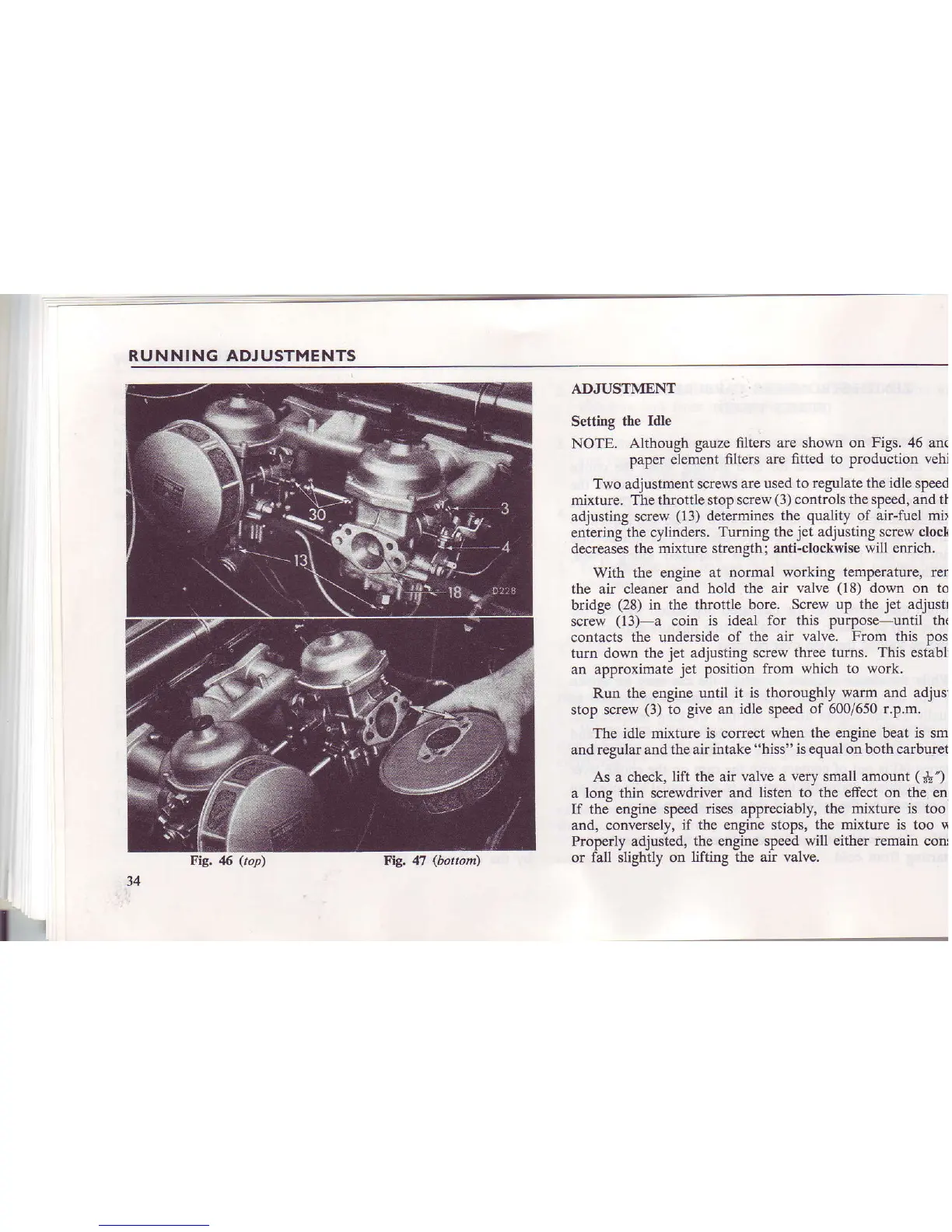

NOTE.

Although gauze

fi1te6 are shown on

Figs.

46 ana

paper element

filters are

fitted to

production

vehi

Two adjustment

screws arc used

to regulate the idle

speed

mixture. The throttle stop screw

(3)

controls the speed, and tl

adjusting screw

(13)

determines lhe quality of air-fuel

mi>

enlerjng the cylinders.

Turning

the

jet

adjusting screw clock

decreases

the mixture strength; anti-clockwise

will enrich,

With the engine

at nomal working

temperature,

ren

the

air

cleaner and hold the air

valve

(18)

down on to

bridge

(28)

in the throttle bore.

Screw up the

jet

adjustl

screw

(13)

a coin

is ideal for this purpose-until th(

contacts

the undenide of the air

valve. From this

pos

turn dow[ the

jet

adjusting

screw three tums. This establi

an approximate

jet

position from

which to work.

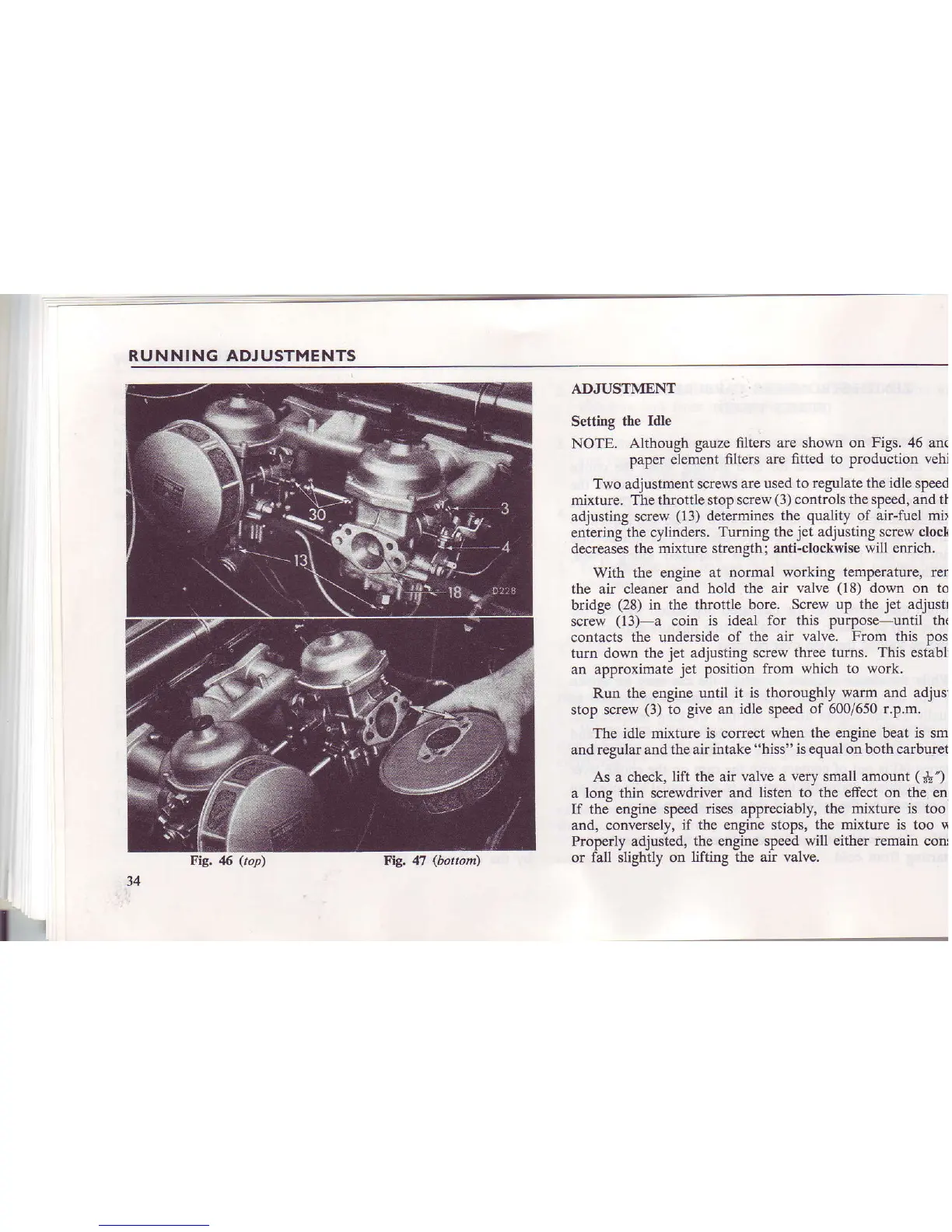

Run the engine

until it is thoroughly

warm

and adjusl

stop screw

(3)

to give an idle speed

of 600/650 r.p.m.

The idle

mixture is corlect when the engine beat is sm

and regular and the air intake

"hiss"

is equal o--n both carburet

As

a

check, lift the air

valve a very small amount

(j!)

a long thin screwdriver

and listen to the effect oll the eni

If

the

engine

speed rises appreciably,

the mixture is too

and, conversely,

if the engine stops, the mixture is too !i

Properly adjusted,

the engine speed

will

either remain coru

or fall slightly on

lifting the air valve.

I

34

Big. 46

(top)

FE 47

(bottom')

Loading...

Loading...